Metal electroslag remelting and smelting equipment

A technology of electroslag remelting and equipment, which is applied in the field of metal smelting, can solve problems that cannot be solved, and achieve the effects of reducing point segregation, improving purity, and reducing sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in combination with specific embodiments.

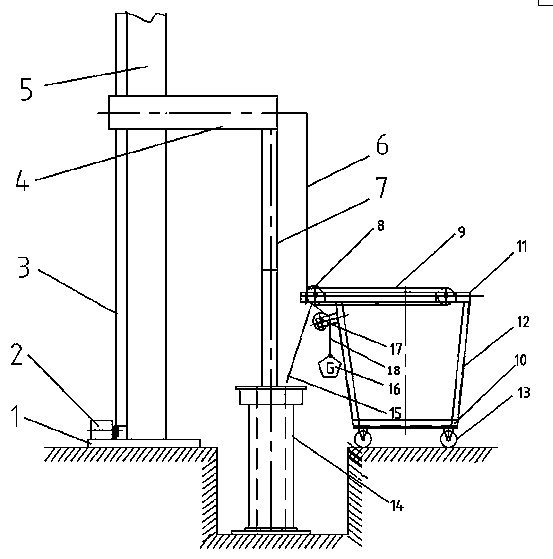

[0025] During specific implementation: if figure 1 As shown, a metal electroslag remelting smelting equipment includes a furnace-shaped crystallizer 14 as a whole, the crystallizer 14 is located in a crystallizer installation groove, and also includes a column 5 located on one side of the crystallizer installation groove, above the column 5 A transverse cantilever 4 is provided, and an electrode 7 extending downward into the crystallizer is installed on the transverse cantilever 4 against the electrode chuck facing the crystallizer 14, wherein it also includes an auxiliary material automatic dosing device positioned at the side of the crystallizer, and the auxiliary material The automatic dosing device includes a discharge part structure and a power control part structure.

[0026] Wherein, the structure of the discharge part includes a frame 12 arranged on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com