A kind of production method for preparing special fertilizer for ginger by-product of ammonium dihydrogen phosphate

A technology of ammonium dihydrogen phosphate and a production method, applied in the directions of phosphate, phosphorus oxyacid, application, etc., can solve the problems of slowing down of ginger growth, stoppage, and inability to supply ginger with nutrients, and achieves improved element content, good absorption rate, The effect of reducing planting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

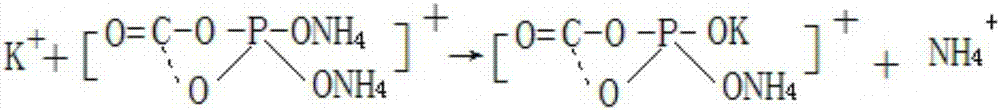

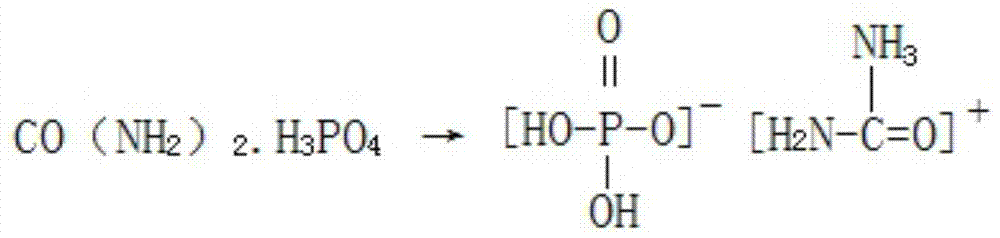

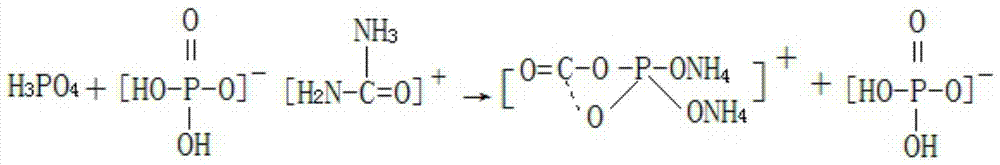

Method used

Image

Examples

Embodiment 1

[0049] A kind of production method of preparing ammonium dihydrogen phosphate by-product ginger special fertilizer provided by the present embodiment mainly comprises the following steps:

[0050] 1) Phosphoric acid and carbonamide are mixed according to the molar ratio of 1.2:1, and the temperature is raised from 80°C to 160°C at a heating rate of 8°C / min. After reaching 160°C, the reaction is stirred for 4 hours, and the intermediate is separated, and then Add the intermediate to the aqueous ammonia solution, the molar ratio of the intermediate to the ammonia water is 1:1.4, adjust the temperature to 65°C, stir and react for 4 hours, after the reaction is completed, perform cooling crystallization and filtration, the crystallization temperature is 35°C, and the filtrate is cooled Circular crystallization treatment in the crystallizer, the obtained filter cake is ammonium dihydrogen phosphate product, and the component content in the filtrate is detected;

[0051] 2) adding c...

Embodiment 2

[0056] A kind of production method of preparing ammonium dihydrogen phosphate by-product ginger special fertilizer provided by the present embodiment mainly comprises the following steps:

[0057] 1) Phosphoric acid and carbonamide are mixed according to the molar ratio of 1.4:1, and the temperature is raised from 80°C to 160°C at a heating rate of 5°C / min. After reaching 160°C, the reaction is stirred for 4 hours, and the intermediate is obtained by separation. Add the intermediate to the aqueous ammonia solution, the molar ratio of the intermediate to the ammonia water is 1:1.2, adjust the temperature to 50°C, stir and react for 5h, after the reaction, perform cooling crystallization and filtration, the crystallization temperature is 30°C, and the filtrate is cooled Circular crystallization treatment in the crystallizer, the obtained filter cake is ammonium dihydrogen phosphate product, and the component content in the filtrate is detected;

[0058] 2) in the filtrate, addin...

Embodiment 3

[0063] A kind of production method of preparing ammonium dihydrogen phosphate by-product ginger special fertilizer provided by the present embodiment mainly comprises the following steps:

[0064] 1) Phosphoric acid and carbonamide are mixed according to the molar ratio of 1.3:1, and the temperature is raised from 80°C to 160°C at a heating rate of 6°C / min. After reaching 160°C, the reaction is stirred for 3.5 hours, and the intermediate is separated. Then add the intermediate to the aqueous ammonia solution, the molar ratio of the intermediate to the ammonia water is 1:1.3, adjust the temperature to 60°C, stir and react for 4.5h, after the reaction, carry out cooling crystallization and filtration treatment, the crystallization temperature is 32°C, make the filtrate The crystallization process is circulated in the cooling crystallizer, and the obtained filter cake is ammonium dihydrogen phosphate product, and the component content in the filtrate is detected;

[0065] 2) addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com