Automatic waste embryo barreling machine for avian influenza vaccine production process

A vaccine production and avian influenza technology, which is applied to conveyor objects, transportation and packaging, stacking of objects, etc., can solve problems such as reducing production efficiency, adversely affecting the occupational health of employees, and harming operators, and achieves improved automation. The effect of reducing the labor intensity of employees and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with the accompanying drawings, the timely solution of the present invention is clearly and completely described through specific embodiments, but the present invention is not limited to the following embodiments. Within the scope of the present invention or without departing from the content, spirit and scope of the present invention, the waste embryo automatic barreling device and its component parts for a kind of avian influenza vaccine production process described in the present invention are scaled down or enlarged, replaced The materials and / or components of the waste embryo automatic barreling device used in the production process of the avian influenza vaccine are obvious to those skilled in the art, and they are all considered to be included in the scope of the present invention.

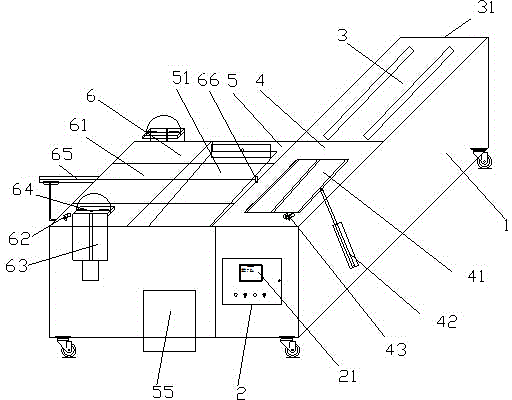

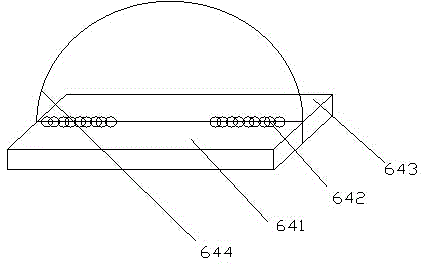

[0018] See attached figure 1 , 2 And 3, a waste embryo automatic barreling machine for a bird flu vaccine production process of the present invention, incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com