Unloading system for bars and sections

A bar and section steel technology, which is applied in the field of steel loading system, can solve the problems of high equipment cost, easy to overturn, low utilization rate of cooling bed, etc., and achieve the effect of reducing equipment cost, stable transfer process, and improving steel loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

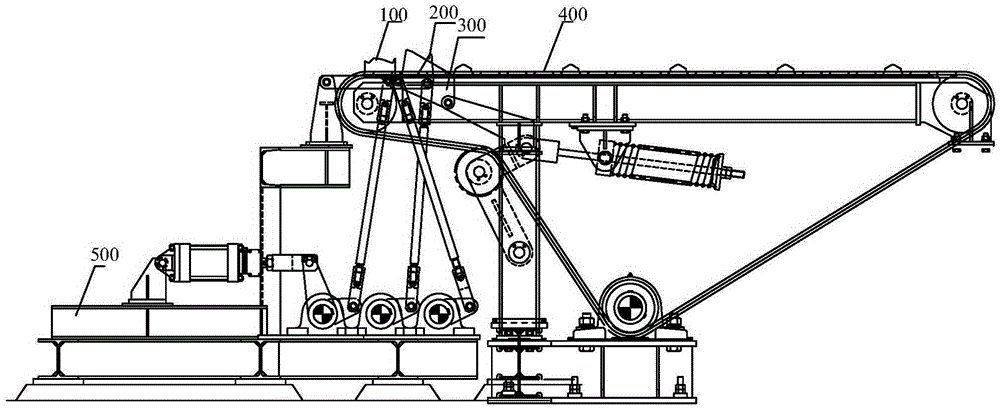

[0042] The steel lowering system applicable to bars and shaped steels in this embodiment includes a stepping lowered steel device, an auxiliary lowered steel device and a conveying device for transporting the bars or shaped steels. With the assistance of the auxiliary lowering device, the stepping lowering device can lower steel for both profiled steel and bars.

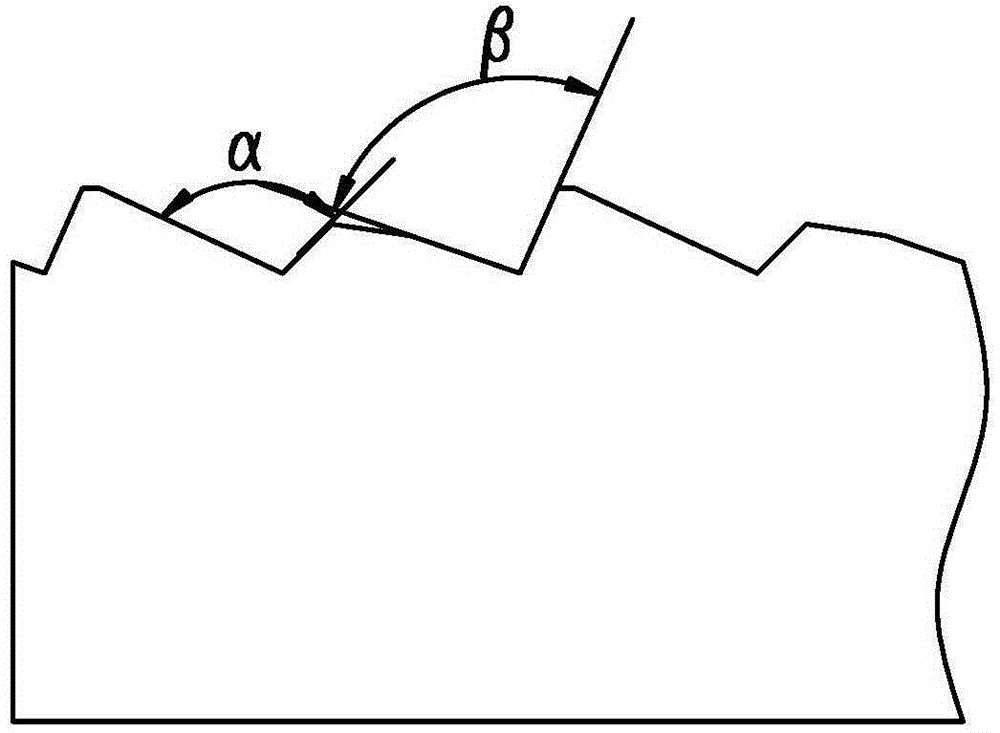

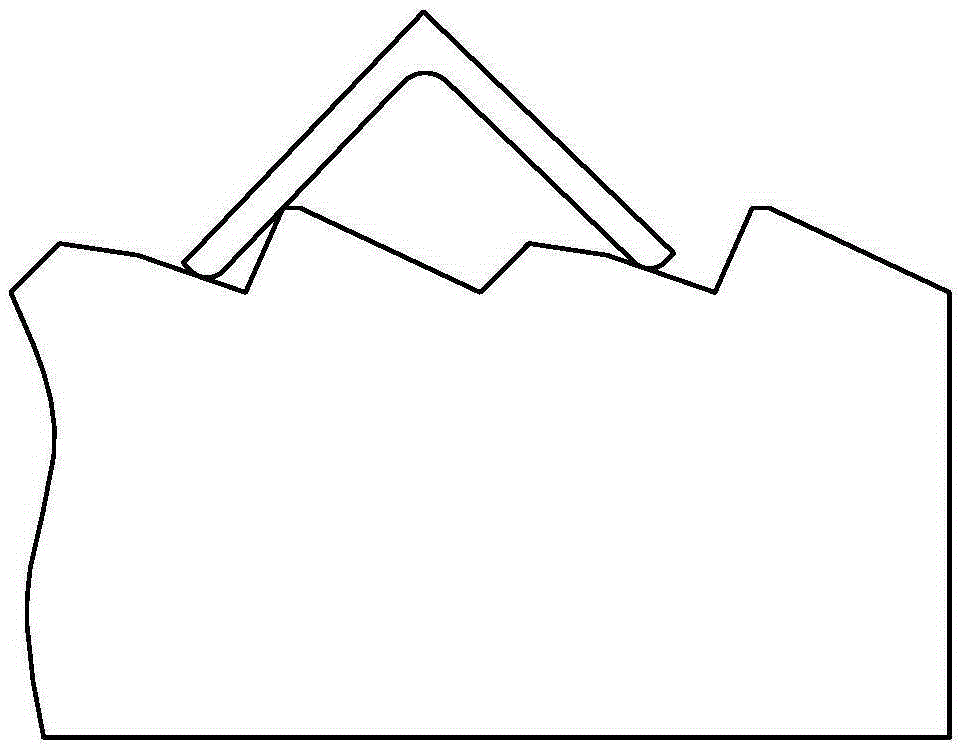

[0043] The stepping steel lowering device includes a movable rack, a static rack and a rack driving device for driving the movable rack to move steppingly. The movable rack and the static rack have the same tooth profile, and both are provided with a number of recesses for placing rods or profiles. The tooth shape of the movable rack in this embodiment is different from that in the prior art, and the opening angles of any two adjacent recesses on the movable rack in this embodiment are different. This setting is for the stability of the moving process and no overturning during the process of transferring the profile...

Embodiment 2

[0059] In this embodiment, on the basis of the above-mentioned embodiments, a bar grouping steel lowering device is provided, and the bar material grouping steel lowering device is set between the auxiliary steel lowering device and the conveying device, and is used for specifications smaller than The bars are grouped under steel. The steel bar grouping device includes a stop device and a sliding device.

[0060] The stop device 200 includes a stop baffle 206, a second driving device 201 and a second transmission device connected to the power output end of the second drive device, and the second drive device controls the stop device through the second transmission device. The movable baffle is in high or low position.

[0061] The second transmission device includes a third connecting rod 202, a second transmission shaft 203, a fourth connecting rod 204, a second screw rod 205, and a flat head. The third connecting rod 202 and the fourth connecting rod 204 are arranged on t...

Embodiment 3

[0077] In this embodiment, on the basis of the above-mentioned embodiment 1, five conveyor chain stoppers 409 are arranged on the conveyor chain, and these five conveyor chain stoppers divide the conveyor chain into four lower steel areas, and each two lower steel areas are One group is divided into two groups to realize the simultaneous conveying of two groups of rolled pieces. In this embodiment, the conveying chain is divided into regions using chain stoppers, so that the number of rolling pieces in each region is relatively reduced, and the two ends of each region are controlled by chain stoppers, so the arrangement of the rolling pieces is more neat and orderly . In the follow-up work, the processes of straightening the section steel in rows and cold shearing and sectioning of the bar are smoother, which improves the work efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com