Mold stacking method of high-precision integral anode chamber for conductive FRP electrostatic demister

A technology of conductive FRP and electric demister, which is applied in the field of conductive FRP electric demister, can solve the problems of large size deviation of the anode chamber, low work efficiency and high production cost, so as to reduce production cost, improve work efficiency and reduce size deviation small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0043] The stacking method of the high-precision integral anode chamber for the conductive glass fiber reinforced plastic electrostatic demister of the present invention comprises the following steps:

[0044] The first step, prepare the mold

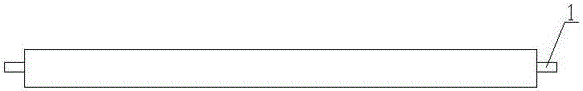

[0045] The mold is a mold with a steel skeleton covered with a glass fiber reinforced plastic structure, and the number of molds is not less than the number of anode tubes required by the overall anode chamber to be produced. Such as figure 1 with figure 2 As shown, the mold is columnar, and its cross section is a regular hexagon. Both ends of the mold have outwardly protruding cylinders 1. The axes of the cylinders 1 coincide with the axes of the mould, and the surface of the mold is processed flat and smooth.

[0046] The second step is to prepare the stacking platform

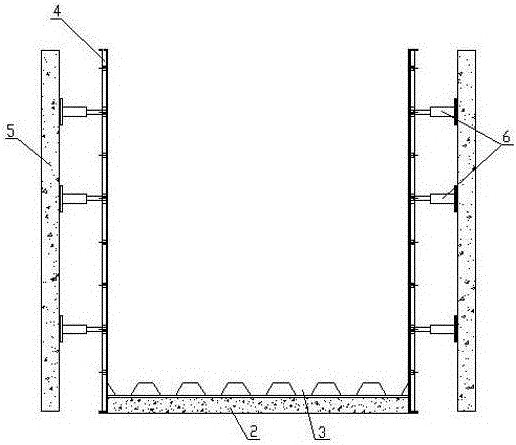

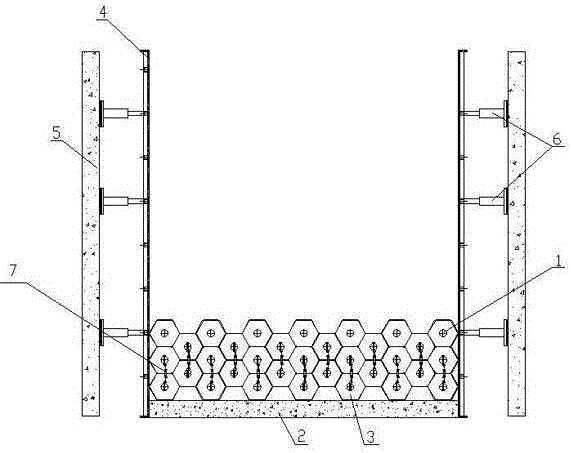

[0047] Such as image 3As shown, the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com