High-speed gearbox processing method

A processing method and gearbox technology, applied in the field of gearbox processing, can solve the problems of large coaxiality error of bearing holes on the gearbox, inaccurate positions of screw holes and positioning pin holes, etc., to ensure quality, ensure positioning accuracy, The effect of ensuring the degree of position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

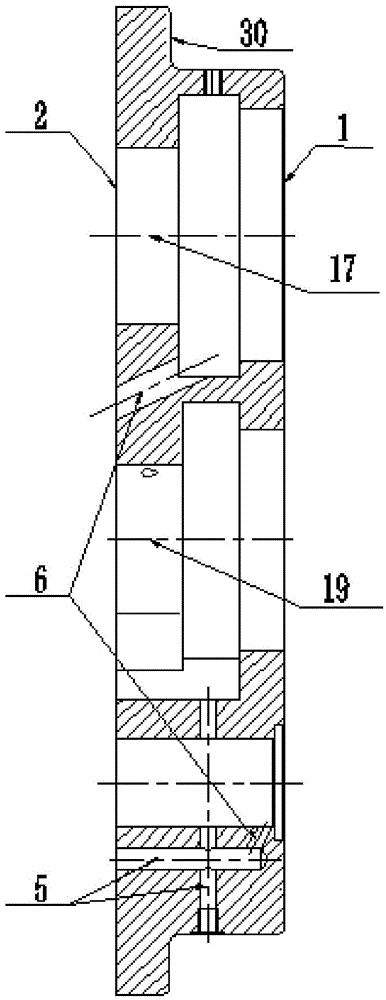

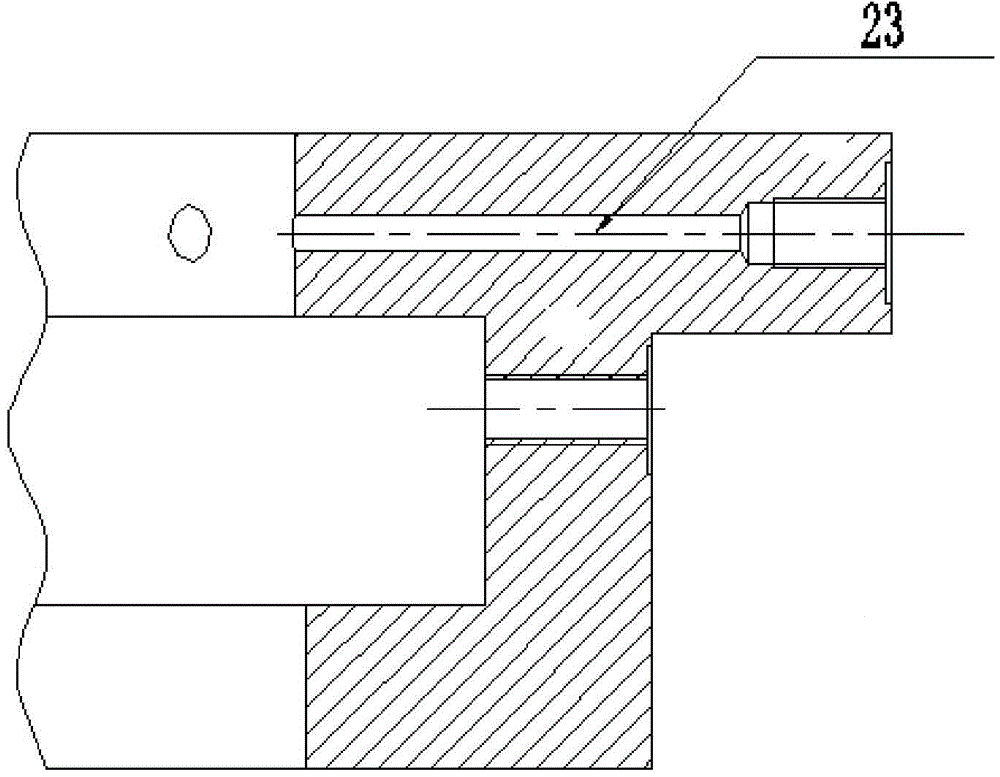

[0061] The specific implementation manner of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0062] Such as Figure 1-12 Shown, a kind of high-speed gearbox processing method comprises the following steps:

[0063] a. Rough processing of the back cover:

[0064] a1. Remove the nodules and residual sand inside the blank of the back cover casting;

[0065] a2. Back cover castings are annealed to relieve stress;

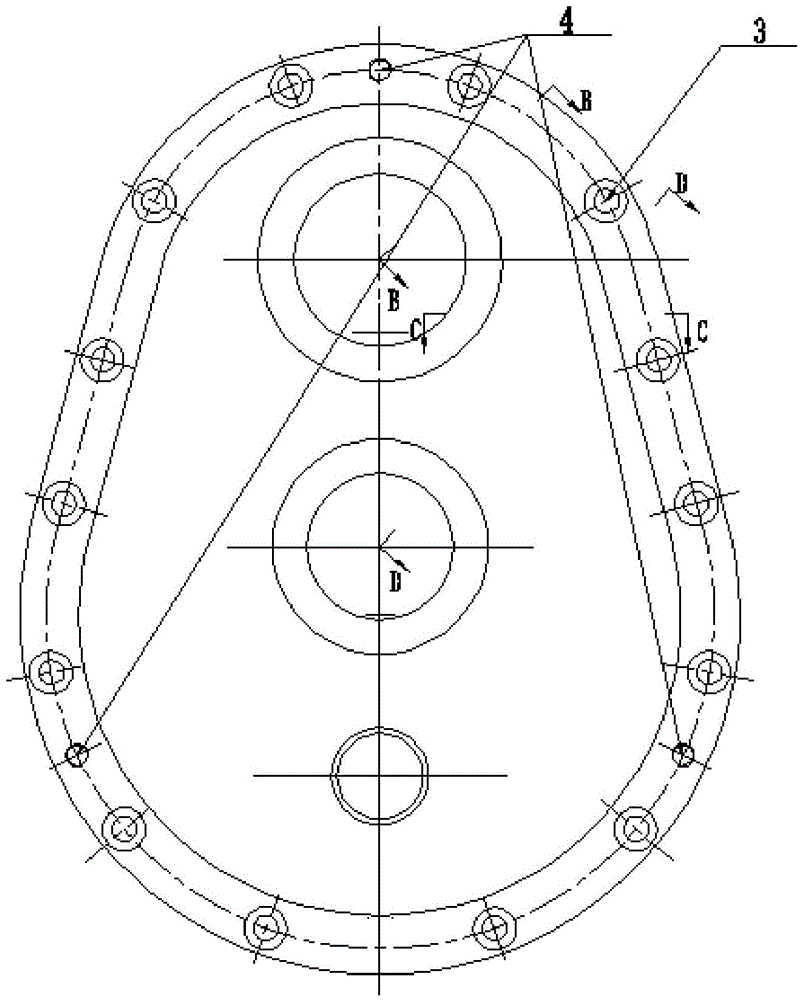

[0066] a3. Based on the step surface 30 of the back cover, draw the starting processing line of the end face 1 of the back cover and the bonding surface 2 with the body, and the alignment lines of the bearing holes of all levels on the back cover;

[0067] a4. Roughly turn the end face of the rear cover according to the starting size and marking line 1;

[0068] a5. Laying surface 2 between the rough car turned over and the body;

[0069] a6. Drill the connection through hole 3, drill and tap the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com