Constant-velocity universal joint jacket comprehensively-measuring, grouping and engraving machine

A technology of constant velocity universal joint and comprehensive measurement, which is applied in the field of mechanical equipment, can solve problems such as easy to cause errors in partition storage, difficult to meet production in turn, and unreliable grouping, etc., to achieve convenient and fast operation and type change, compact structure, and avoid The effect of packet errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific drawings and embodiments.

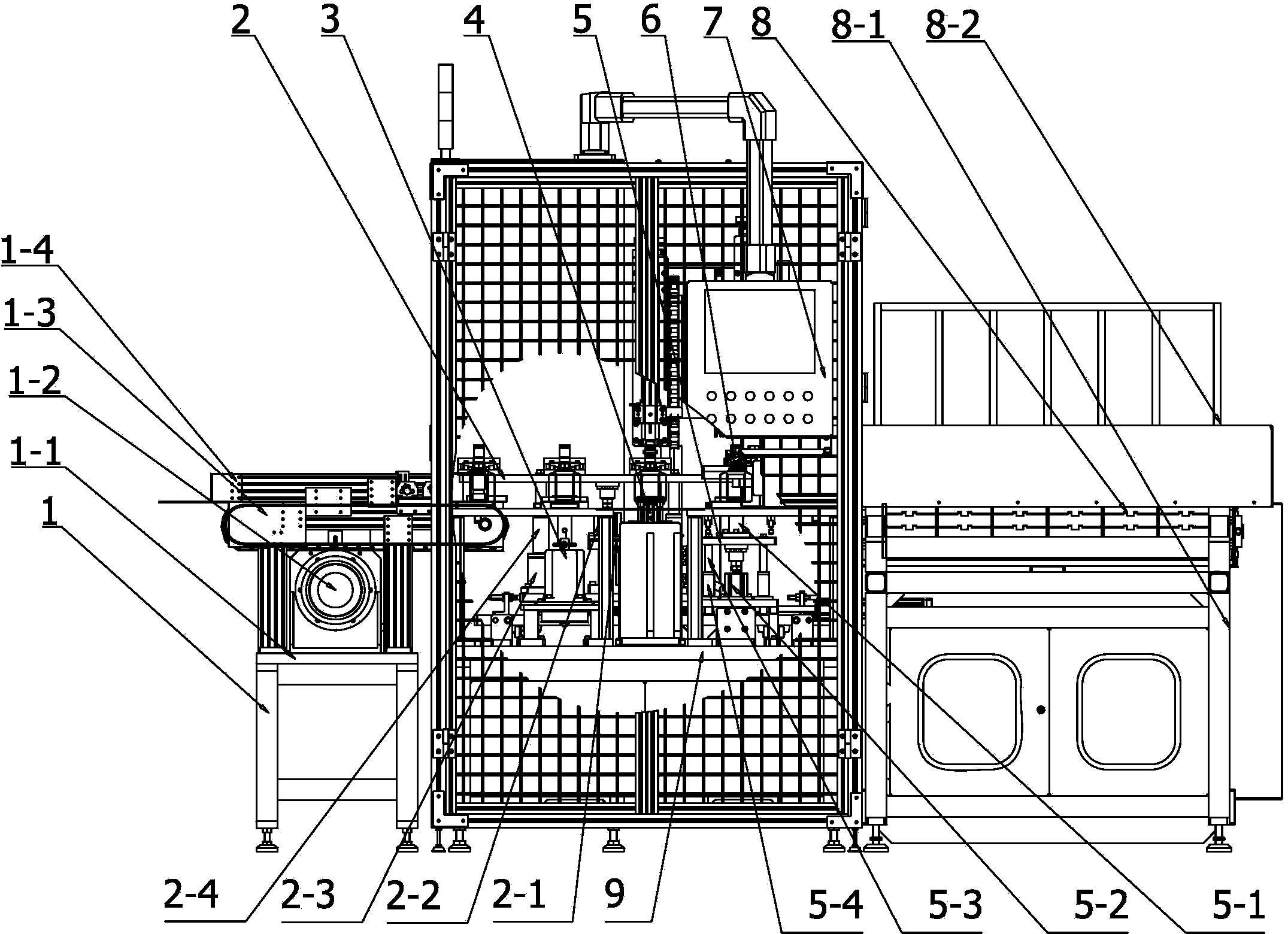

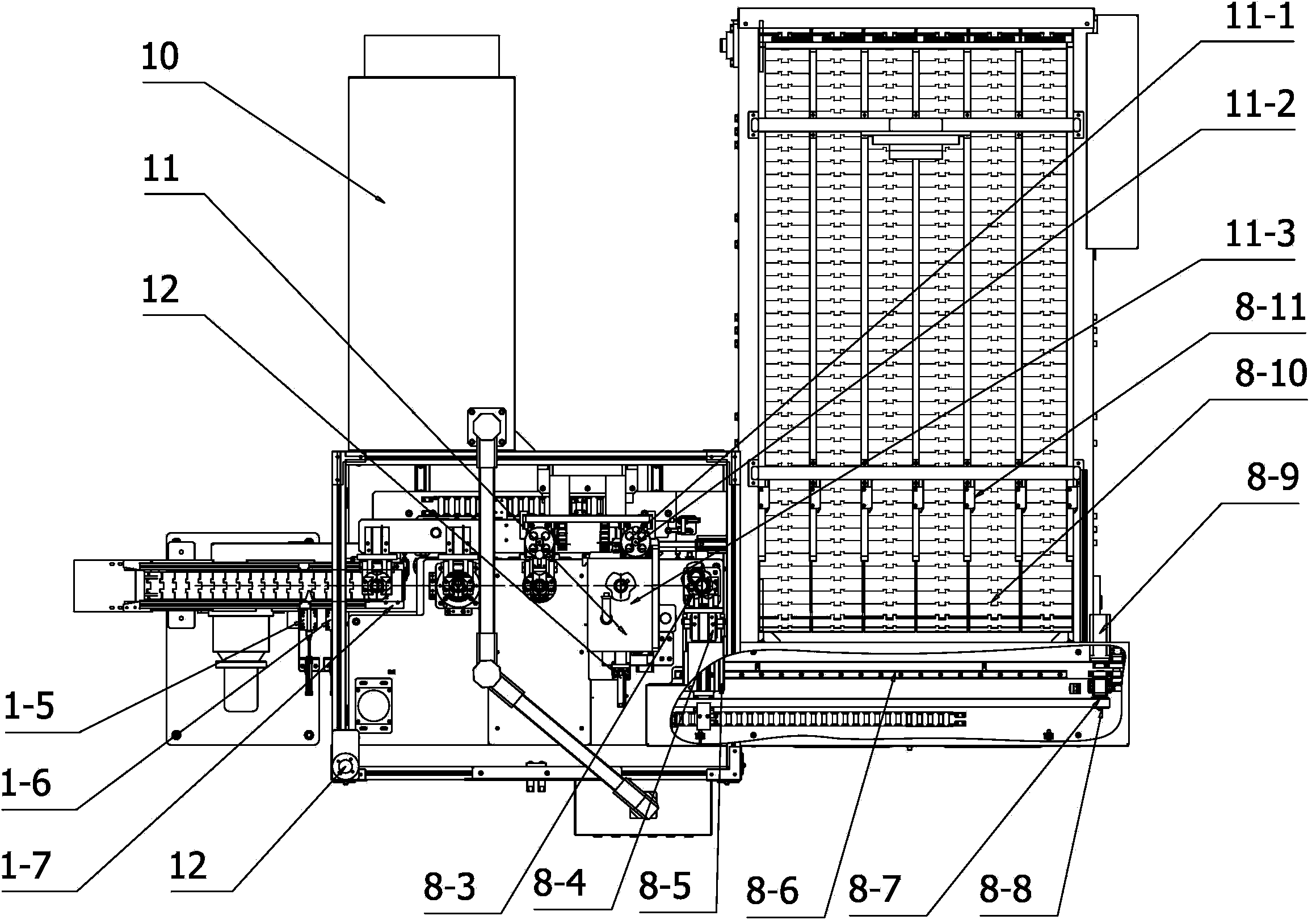

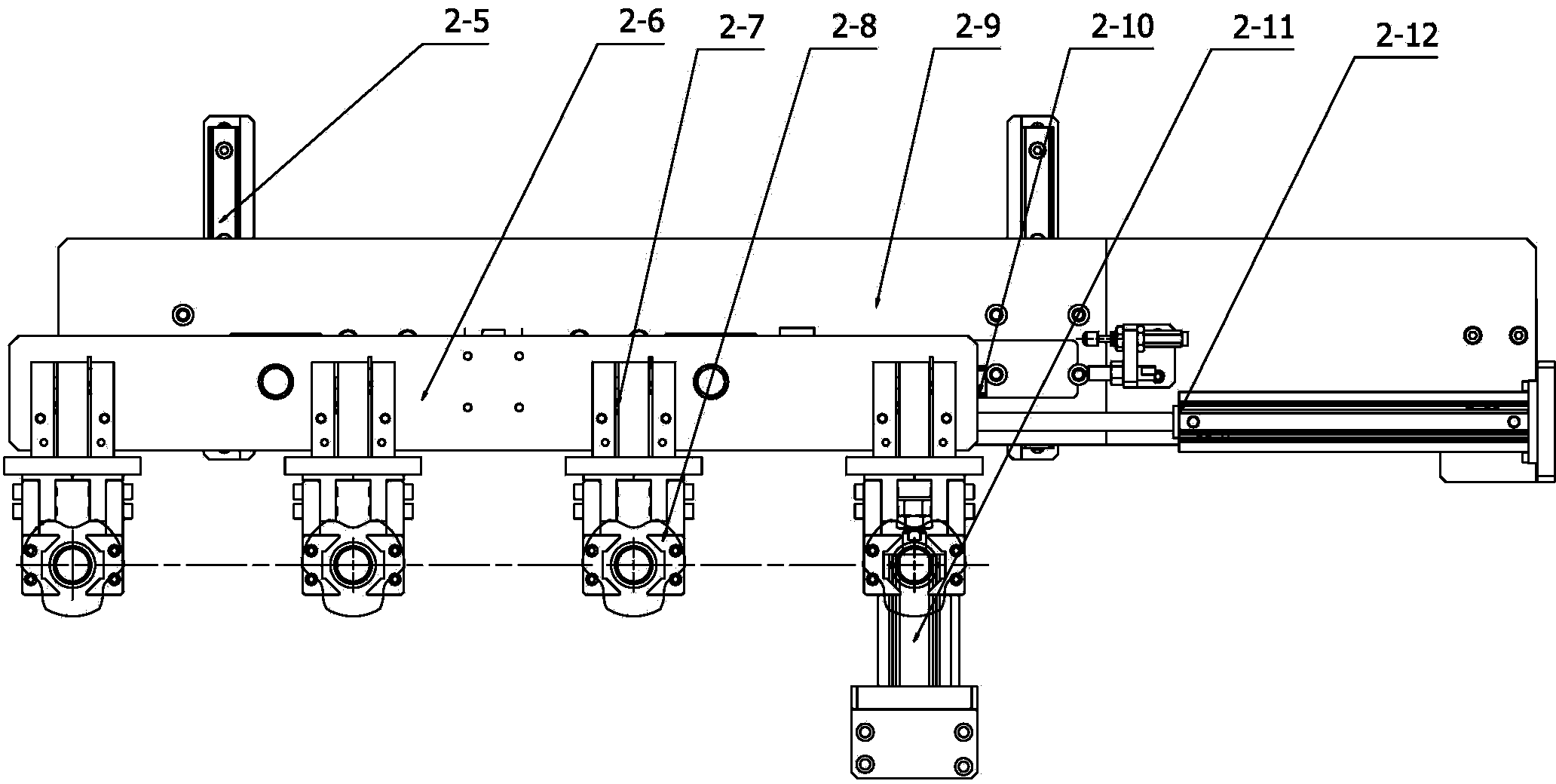

[0024] Such as Figure 1~7As shown, it includes a feeding mechanism 1, a feeding bracket 1-1, a conveying channel 1-2, a feeding guide block 1-3, a first stopper 1-4, a second stopper 1-5, an upper Material positioning block 1-6, material transfer mechanism 2, material transfer plate 2-1, lifting cylinder 2-2, linear bearing 2-3, guide shaft 2-4, material guide rail 2-5, material transfer upper plate 2- 6. Material transfer claw 2-7, material transfer manipulator 2-8, material transfer bottom plate 2-9, material transfer guide rail 2-10, material transfer cylinder 2-11, material transfer cylinder 2-12, rotary positioning mechanism 3 , mounting bracket 3-1, stepper motor 3-2, zero photoelectric switch 3-3, judging photoelectric switch 3-4, profiling rotary positioning block 3-5, spring 3-6, guide sleeve 3-7, rotary Main shaft 3-8, synchronous belt 3-9, synchro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com