Production process of mashed purple sweet potatoes

A production process and technology of purple potato puree, applied in food preparation, application, food science and other directions, can solve problems such as anthocyanin loss, and achieve the effects of natural taste, reducing loss and increasing monosaccharide content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

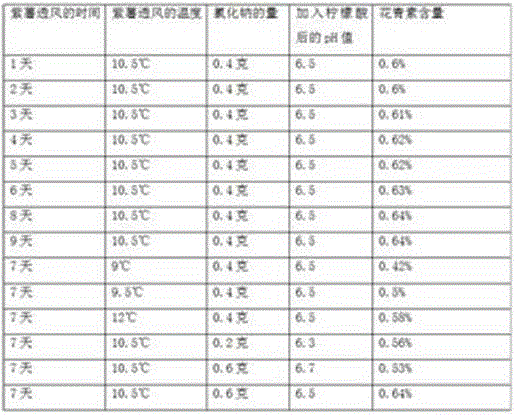

Method used

Image

Examples

Embodiment 1

[0028] A kind of purple sweet potato puree production process, comprises the following steps,

[0029] a. Prepare 100 catties of purple sweet potatoes of the variety "Yuzi 263". Put the purple sweet potatoes in a bamboo basket on a shelf and store them in the dark at 10.5°C for seven days.

[0030] b. Wash and peel the purple sweet potato.

[0031] c. Cut the purple sweet potato into slices about 2cm thick.

[0032] d. Pretreatment: Add 0.4 grams of salt grains to the purple potato slices, and stir well.

[0033] e. Color protection treatment: add 0.1 gram of citric acid granules to the purple sweet potato, and let it stand for 5 minutes after stirring to maintain the pH at ph6.5.

[0034] f. Cook at a temperature of 100°C for 15 minutes.

[0035] g. Pound the purple potato chips into purple potato mash.

[0036] h. Put the purple sweet potato puree into the tank, and use the "9118 type easy-to-pull double air-proof can" package, which is a common form of tinplate cylindri...

Embodiment 2

[0040] The difference from Example 1 is that in step a, the storage time at 11° C. in the dark is 7 days.

[0041] The anthocyanin content of the purple sweet potato puree processed by the ordinary process was 0.15%, and the anthocyanin content of the purple sweet potato processed by this process was 0.62%, and the anthocyanin loss rate was 13.8%. At 11°C, the retention effect on anthocyanins is not as good as at 10.5°C.

Embodiment 3

[0043] The difference from Example 1 is that in step a, the storage time at 11.5° C. in the dark is 7 days.

[0044]The anthocyanin content of the purple sweet potato puree processed by the ordinary process was 0.15%, and the anthocyanin content of the purple sweet potato processed by this process was 0.61%, and the anthocyanin loss rate was 15.2%. At 11.5°C, the retention effect of anthocyanins was not as good as at 11°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com