Uniformly heated transparent conductive film curved windshield and manufacturing method

A transparent conductive film and windshield technology, which is applied to windshields, transparent/reflective heating devices, windows, etc., can solve the problem of uneven heating power density of the film layer, overheating of the curved windshield surface, and inability to uniformly heat the entire area and other issues, to achieve the effect of prolonging the effective life, easy operation, and realizing industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

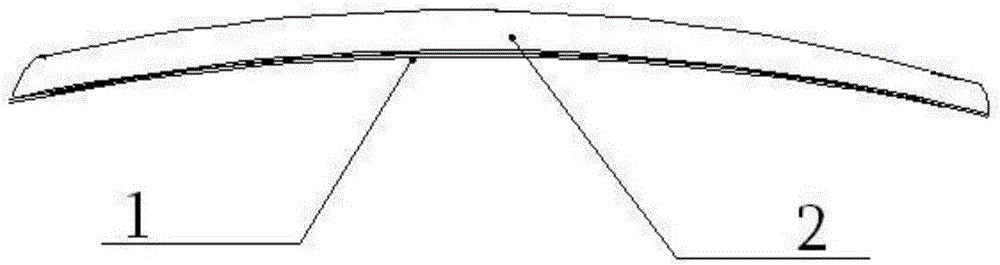

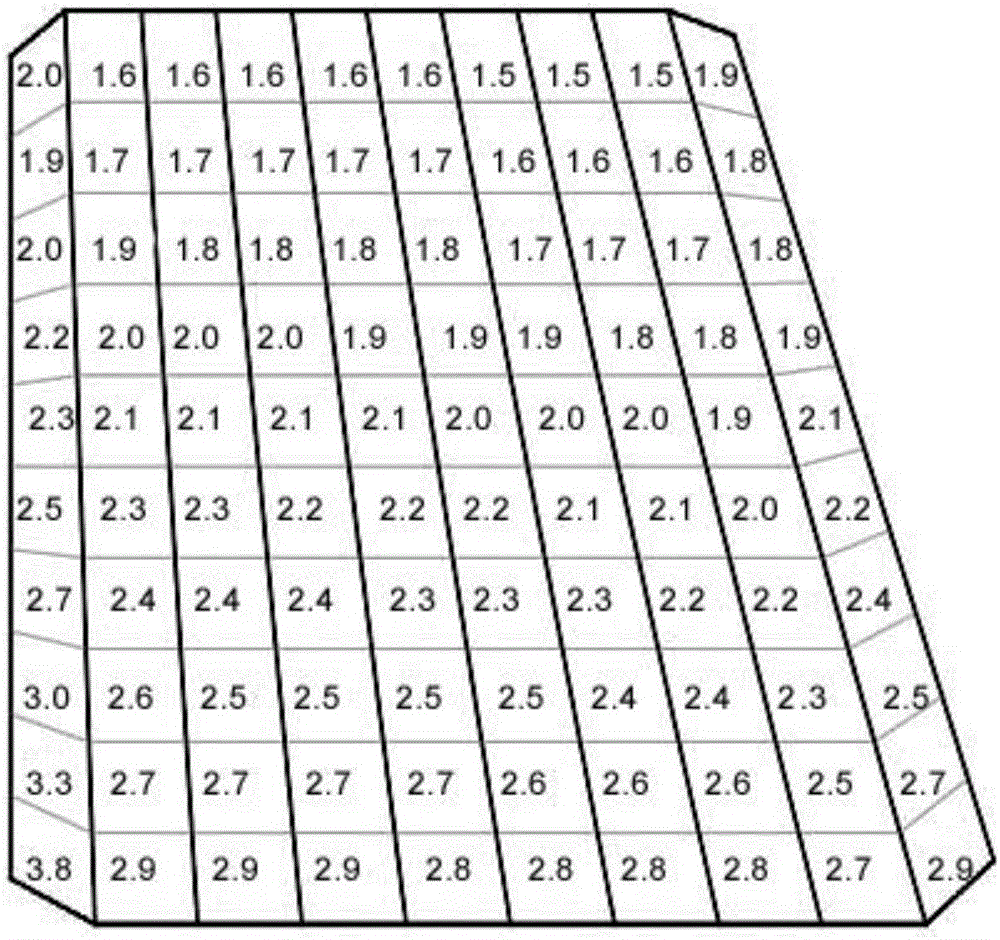

[0025] Such as figure 1 As shown, a curved windshield with a transparent conductive film that is evenly heated includes a curved windshield substrate 1, and a transparent conductive film layer 3 is deposited on the surface of the glass substrate 1; the thickness of the transparent conductive film layer 3 is from the curved surface windshield The glass substrate 1 has a gradient increasing from the upper edge to the lower edge thereof, and the thickness of the conductive film layer 3 decreases gradually from one side edge to the other side edge of the curved windshield substrate 1 .

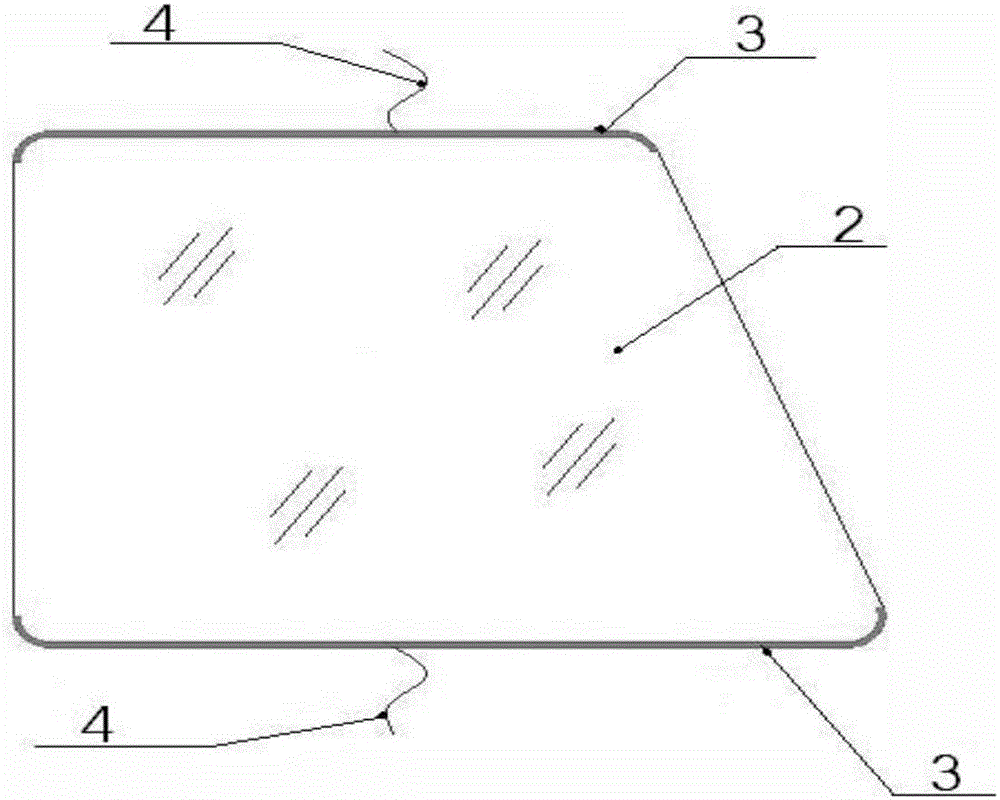

[0026] Such as figure 2 As shown, bus bars 4 are provided on the upper and lower edges of the curved windshield substrate, and the bus bars 4 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com