Positive electrode for lithium sulfur battery

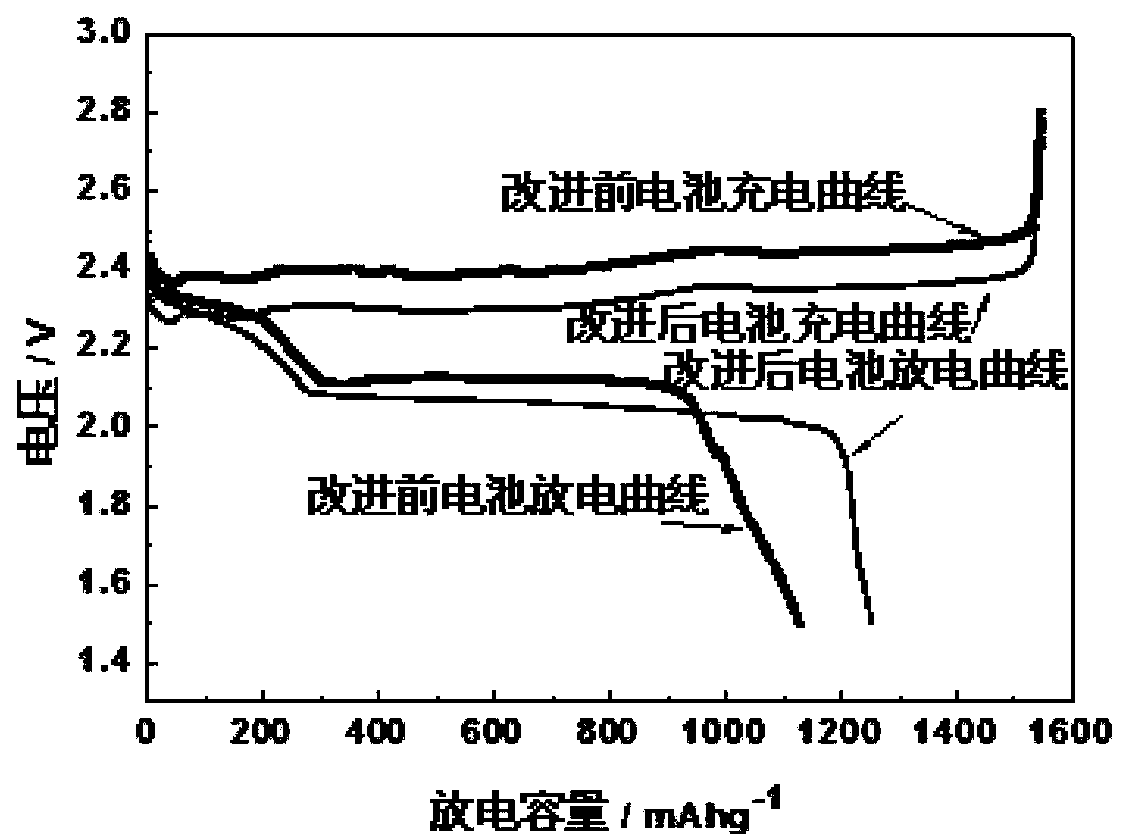

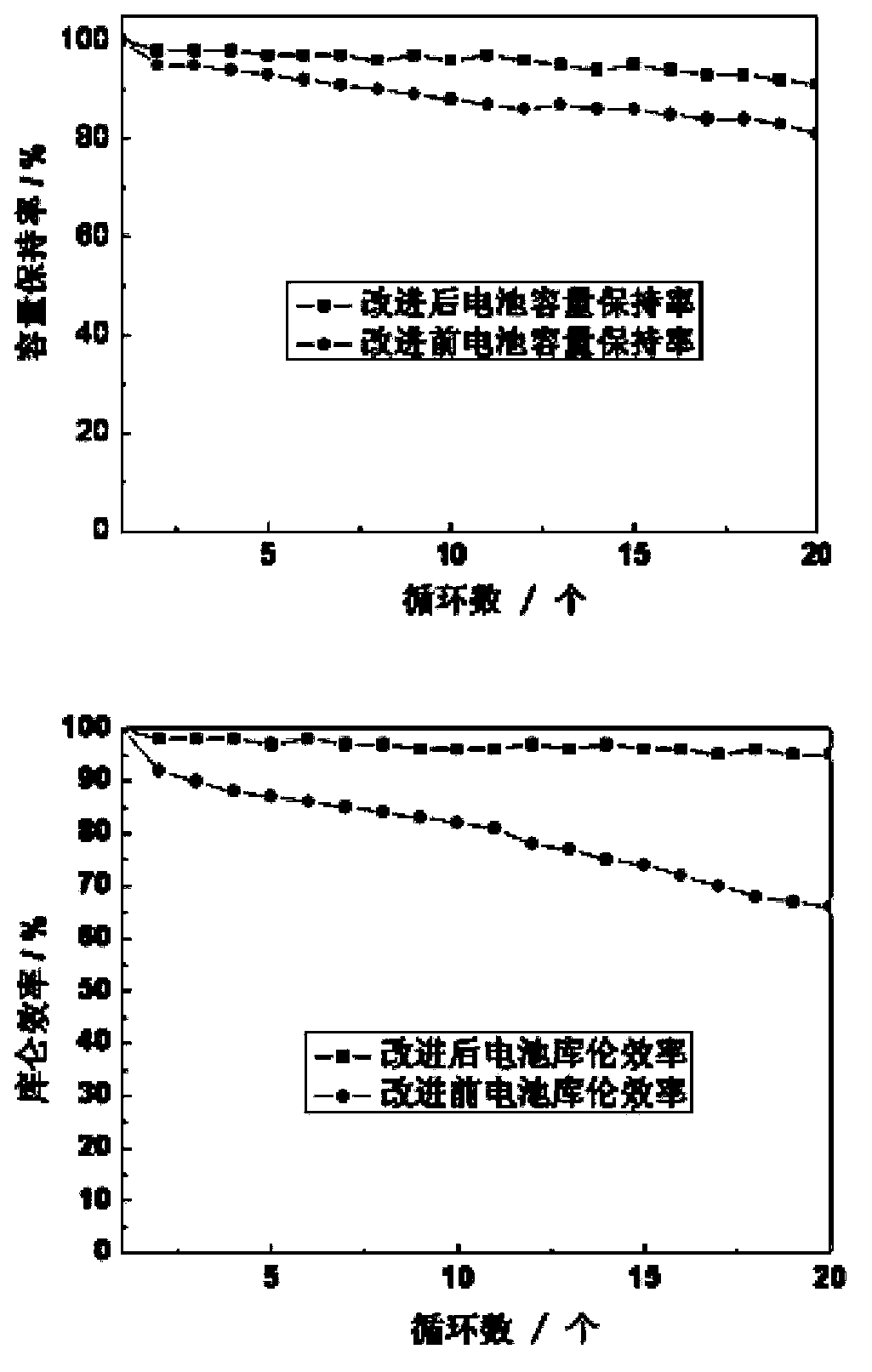

A lithium-sulfur battery and positive electrode technology, applied in the field of lithium-sulfur batteries, can solve the problems of poor electrode reversibility and high rate performance, reduce the utilization rate of active materials, battery cycle capacity attenuation, etc., achieve simple and feasible preparation process, improve cycle stability performance, the effect of reducing the self-discharge phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]Take 1g of sulfur mass content 10% sulfur / activated carbon (cathode material) and add it to 100ml ethylene glycol solution, stir and sonicate for 1h, mix well to form solution A, add 6.67ml chloroauric acid solution (1.5mgAu / ml ), stirred and ultrasonicated for 10 hours, mixed evenly to form solution B, added dropwise 0.5mol / L ethylene glycol sodium hydroxide solution to solution B, adjusted the pH to 9, stirred for 10 minutes, and formed solution C; microwaved solution C for 1 minute , cooled to room temperature to form solution D; add 4mol / L ethylene glycol hydrochloric acid solution to solution D, adjust the pH value to 1, stir for 1h, let stand overnight, form powder E after suction filtration and washing, and mix powder E with acetylene Black and PVDF are ultrasonically mixed in N,N-dimethylformamide (NMP) solution according to the mass ratio of 8:1:1, and then scraped onto the aluminum foil to obtain the positive electrode of the lithium-sulfur battery. The battery ...

Embodiment 2

[0042] Take 1g of sulfur / graphene with a mass content of 95% sulfur (positive grade material) and add it to 500ml of ethylene glycol solution, stir and sonicate for 5h, mix evenly to form solution A, and add chloroauric acid solution containing 1g of Au to solution A , stir and ultrasonic for 1 hour, mix well to form solution B, add 0.5mol / L ethylene glycol sodium carbonate solution dropwise to solution B, adjust the pH value to 12, stir for 120 minutes, and form solution C; microwave solution C for 3 minutes, cool to room temperature to form solution D; add 4mol / L ethylene glycol sulfuric acid solution to solution D, adjust the pH value to 0.9, stir for 6h, let it stand overnight, form powder E after suction filtration and washing, mix powder E with acetylene black, PVDF is ultrasonically mixed in N,N-dimethylformamide (NMP) solution according to the mass ratio of 8:1:1, and then scraped onto the aluminum foil to obtain the positive electrode of lithium-sulfur battery. The bat...

Embodiment 3

[0044] Take 1g of sulfur / carbon nanotubes (positive material) with a sulfur mass content of 70% and add it to 300ml of ethylene glycol solution, stir and sonicate for 3h, mix well to form solution A, and add gold chloride containing 0.0526g of Au to solution A Acid solution, stirred and ultrasonicated for 3 hours, mixed evenly to form solution B, added dropwise 0.5mol / L sodium carbonate solution of ethylene glycol to solution B, adjusted the pH value to 11, stirred for 120min, formed solution C; refluxed and heated solution C Keep at 140°C for 4 hours, cool to room temperature to form solution D; add 4mol / L ethylene glycol sulfuric acid solution to solution D, adjust the pH value to 0.9, stir for 6 hours, stand overnight, and form powder E after suction filtration and washing , Mix powder E, acetylene black, and PVDF in N,N-dimethylformamide (NMP) solution with a mass ratio of 8:1:1, and then apply it on an aluminum foil to obtain a positive electrode for a lithium-sulfur batte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com