Gravity driving type bomb replacing arc extinguishing device

A gravity-driven, arc-extinguishing device technology, which is applied to electrical components, insulators, circuits, etc., can solve the problems of increasing the structural complexity of the arc-extinguishing device, the limited number of arc-extinguishing gas pills, and the limited number of operations, and achieves a simple structure. The effect of ensuring normal and stable work with little change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

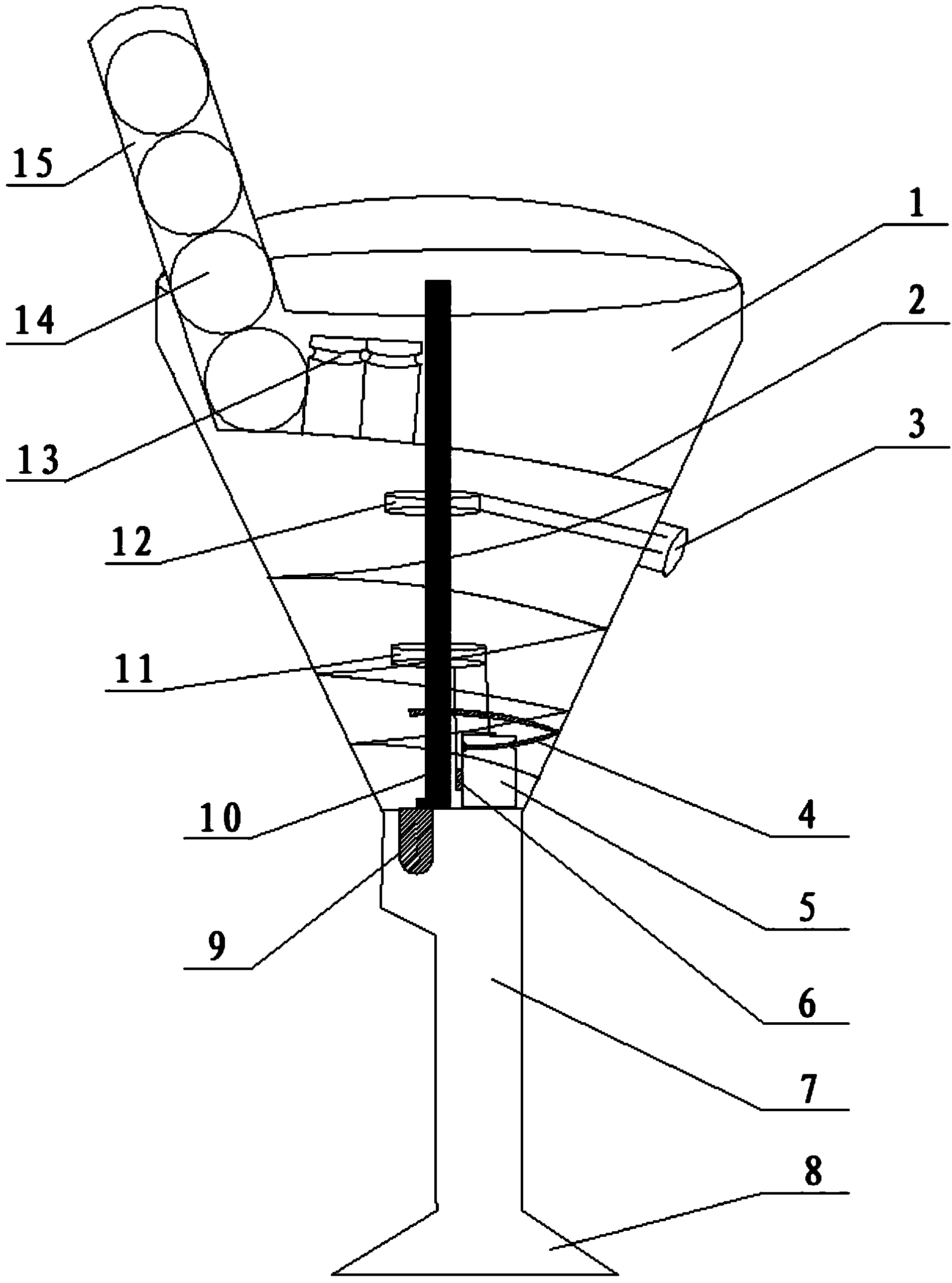

[0030] A gravity-driven arc extinguishing device for reloading, comprising a magazine storage bin 1 and an arc extinguishing cylinder 7; inside the magazine storage bin 1 is provided with a trigger coil 11 and an arc guiding fitting 10 passing through the trigger coil 11, storing The bottom of the magazine 1 is provided with an arc-guiding electrode 9 connected with an arc-guiding fitting 11 and an air pill trigger position, and a side electrode 6 is provided on the side wall of the air pill trigger position; the side electrode 6 is connected to one end of the trigger coil 11 connected, the other end of the trigger coil 11 is connected to the trigger electrode of the arc extinguishing gas pill 5 entering the trigger position of the gas pill; wherein, the inside of the magazine storage bin 1 is provided with a top-down The spiral type air pill forward track 2; the top of the described bomb storage bin 1 is provided with a gravity ball storage bin 15, and the opening of the gravi...

Embodiment 2

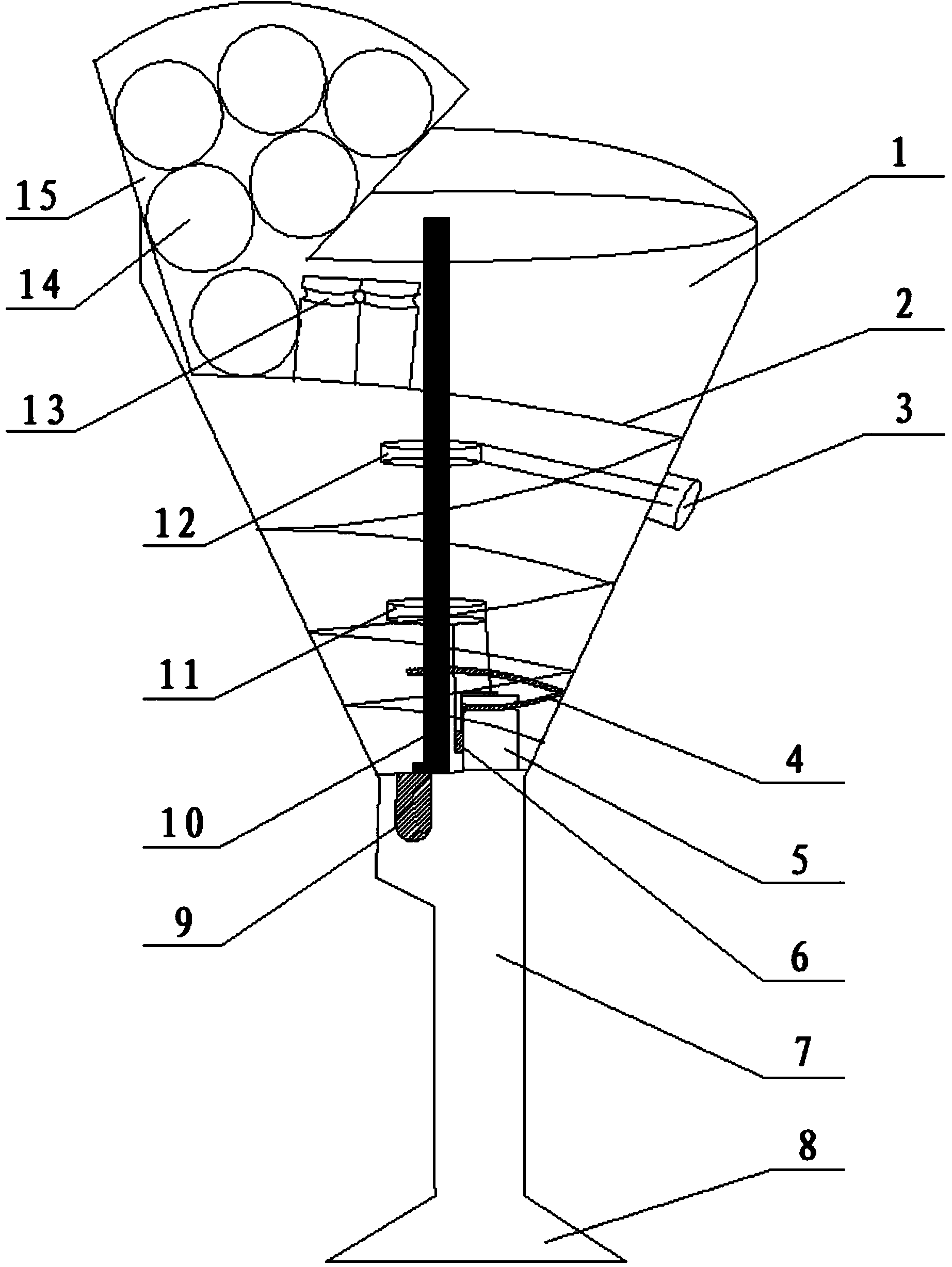

[0035] The difference between this embodiment and Embodiment 1 is that the gravity ball storage bin 15 is funnel-shaped.

Embodiment 3

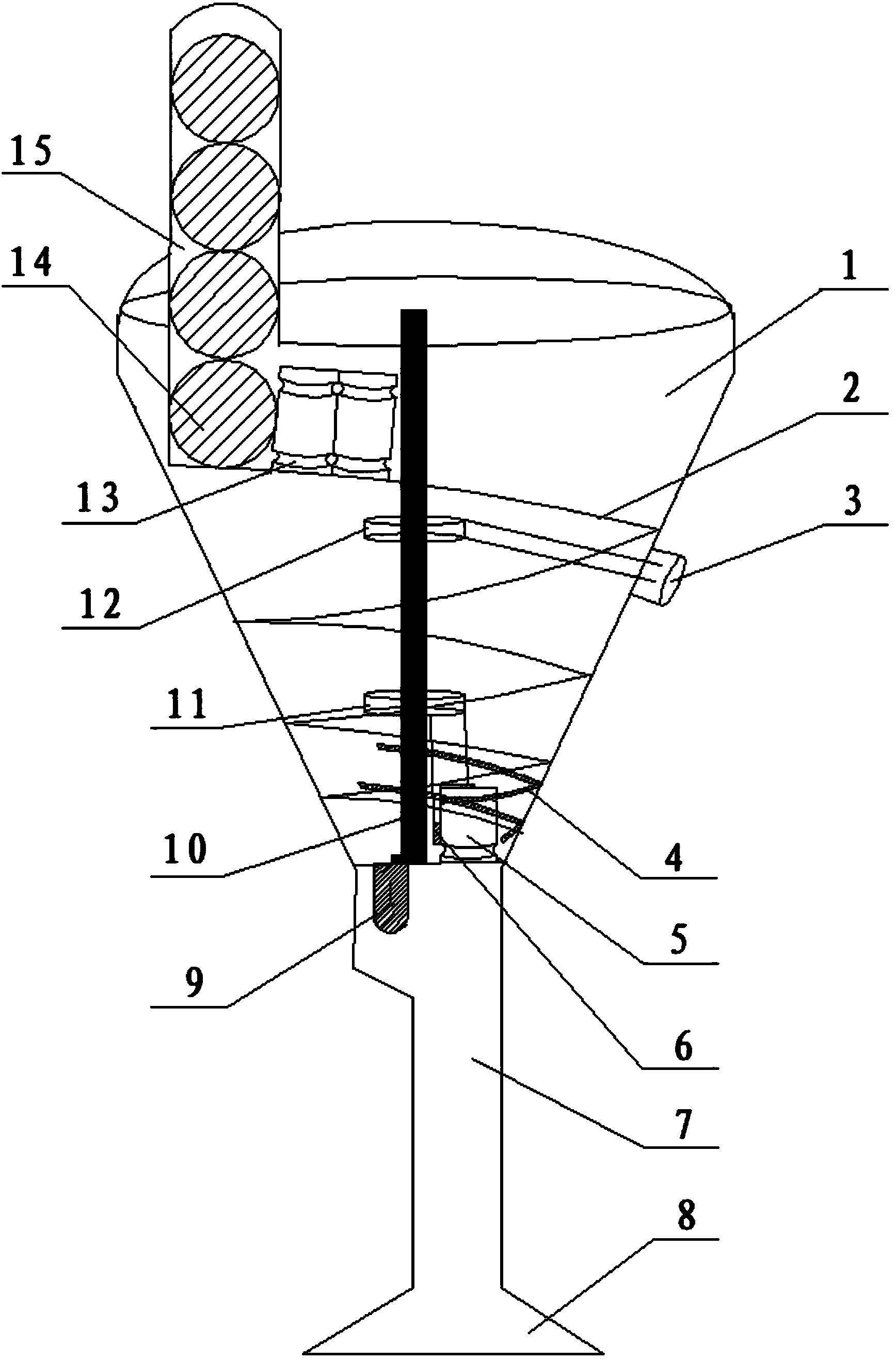

[0037] The difference between the present embodiment and embodiment 1 is that two vertical and parallel suspension rails 4 are arranged on the side wall of the air pellet moving rail 2 at the bottom of the magazine storage bin 1 . Described gravity ball storage bin 15 is linear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com