Two-dimensional touch control sensor of combined structure

A touch sensor, composite structure technology, applied in the input/output process of instruments, data processing, electrical digital data processing, etc. problem, to achieve the effect of high transparency and high additional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Attached below figure 1 ~ Figure 6 to illustrate the specific embodiment of the present invention. It should be understood that the embodiments are specific descriptions of the technical solutions, and do not limit the specific structures of the technical solutions.

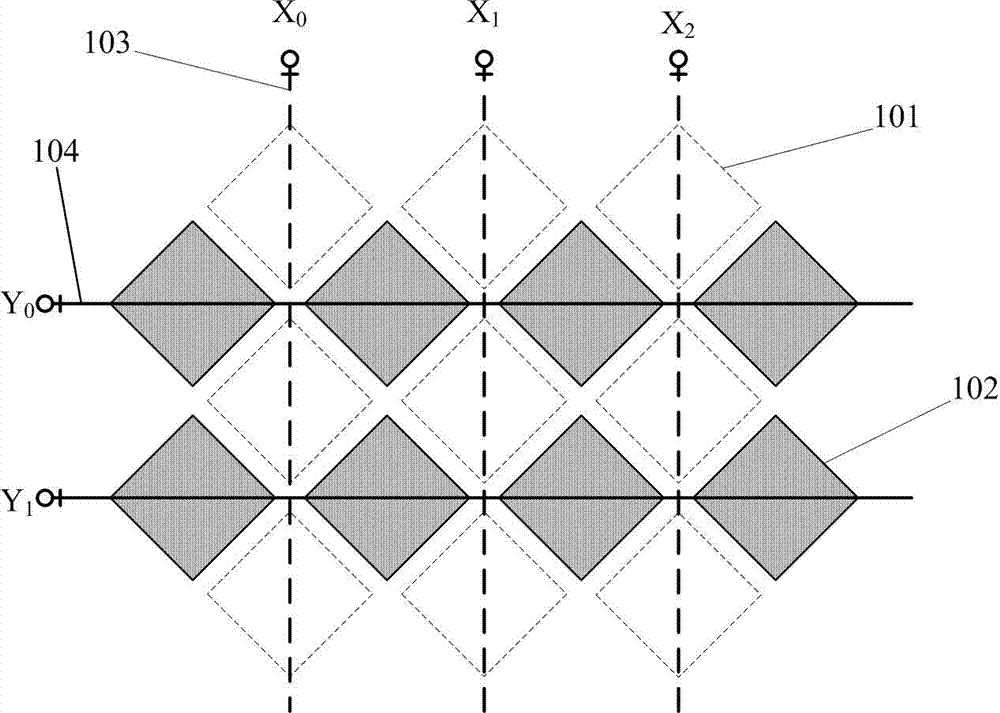

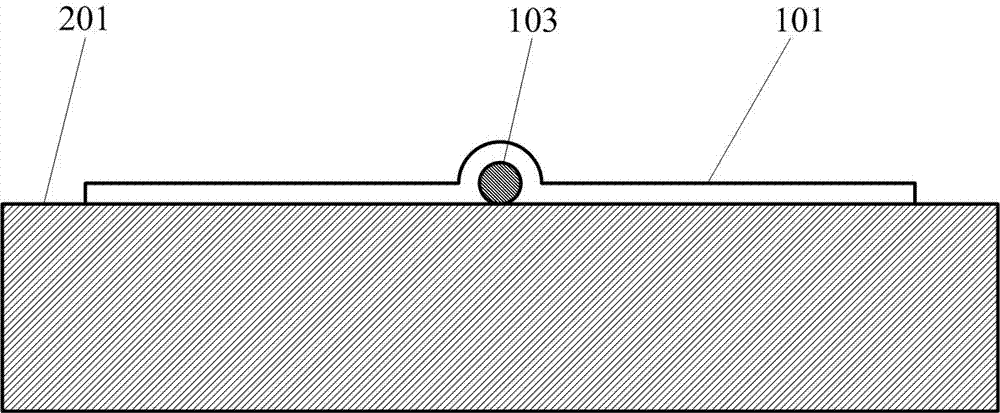

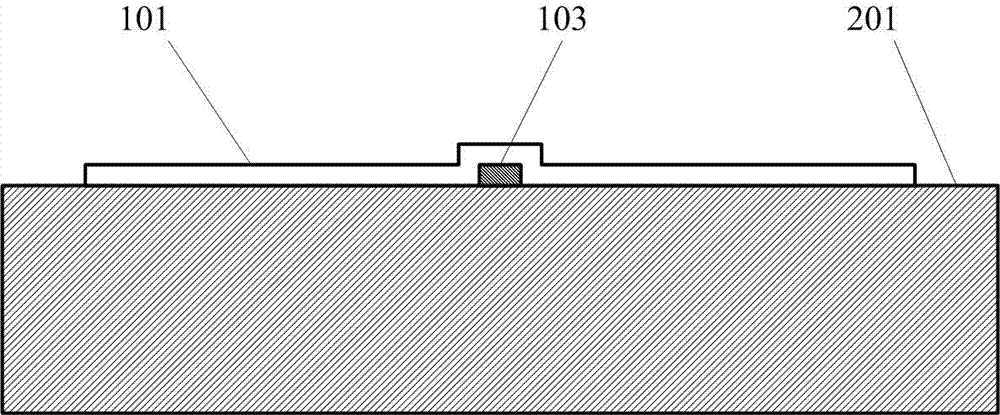

[0031] For the widely used transparent conductive material ITO on capacitive touch screen, there are many alternative materials such as nanometer and organic materials. However, these materials generally have the disadvantage of high resistivity, and it is difficult to be used as a sensing electrode on a capacitive touch screen with a large size. figure 1 The given structure can effectively solve this problem. figure 1 What is given is a two-dimensional sensor including X-direction electrode groups and several Y-direction electrode groups, which can realize the detection of touch points in the plane. exist figure 1 In the X and Y directions, there are X0, X1,... , at least one thin metal wire 103 or 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Square resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com