System and method for detecting orthogonality of precision shafting

A technology of precision shafting and detection system, which is applied to measuring devices, instruments, and optical devices, etc., can solve the problems of high requirements on machining accuracy and increase the difficulty of machining, and achieve the effect of simple method, high precision and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

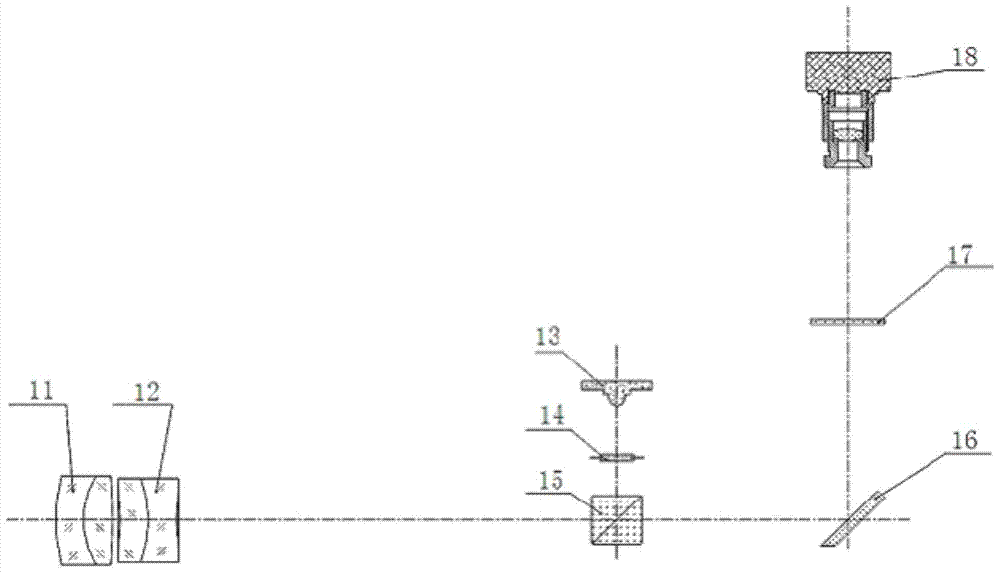

[0026] Such as Figure 5 , 6 As shown, the precision orthogonal shaft system to be tested is set on the detection platform, and the four-dimensional adjustable reticle is installed on the rotating link of the pitching part of the precision orthogonal shaft system to be tested through the adapter plate. The focusing autocollimator in the TV Placed directly in front of the four-dimensional adjustable reticle, it is used for self-alignment and aiming at the reticle.

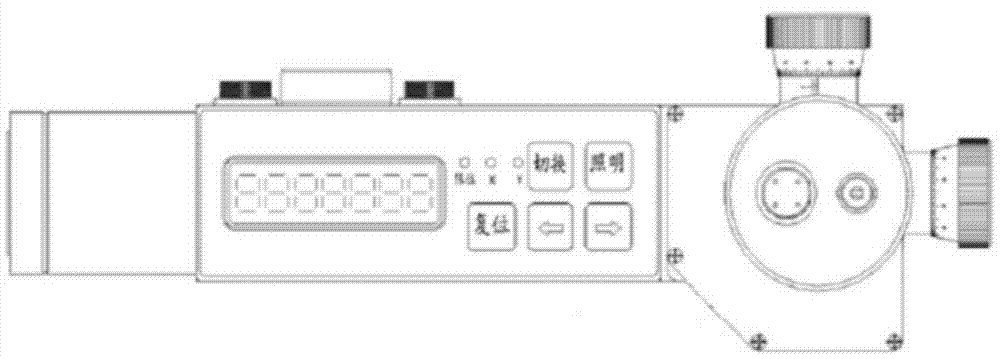

[0027] Such as figure 1 , 2 As shown, the TV internal focusing autocollimator is composed of an internal focusing optical system, a CCD image sensor imaging system, an operation control system mounting seat and the like. Panel operation instructions: "Switch" operation performs limit, X and Y conversion; "Lighting" operation adjusts the brightness of LED lighting, a total of 5 levels of brightness adjustment; "Reset" adjusts the working distance to the parallel light position at the limit, X and Y It is used for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com