Linear motor

A linear motor and coil technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of uneven speed, difficult cooling, complex cooling structure, etc., and achieve the effect of high utilization efficiency, strong mechanical strength, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

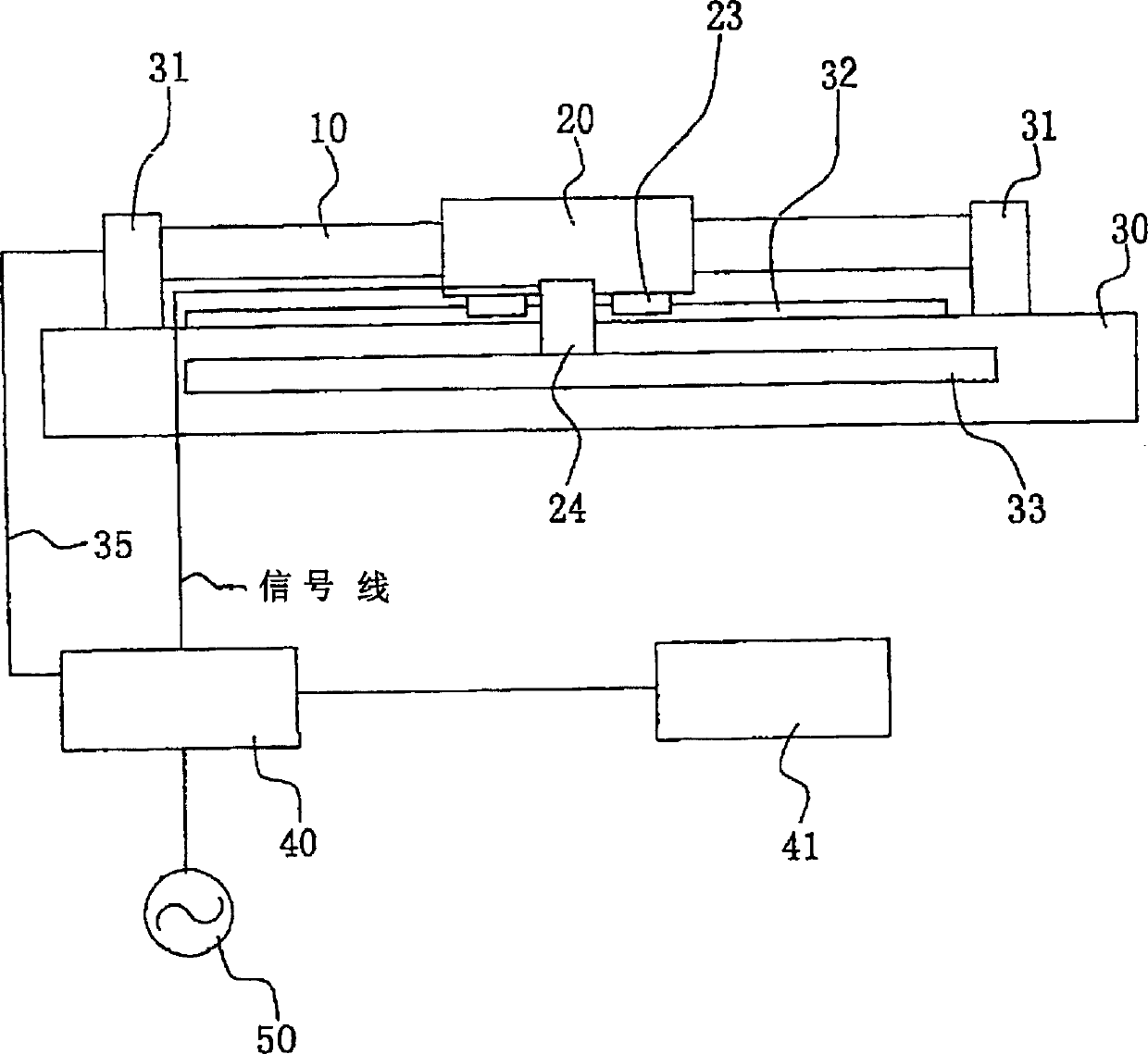

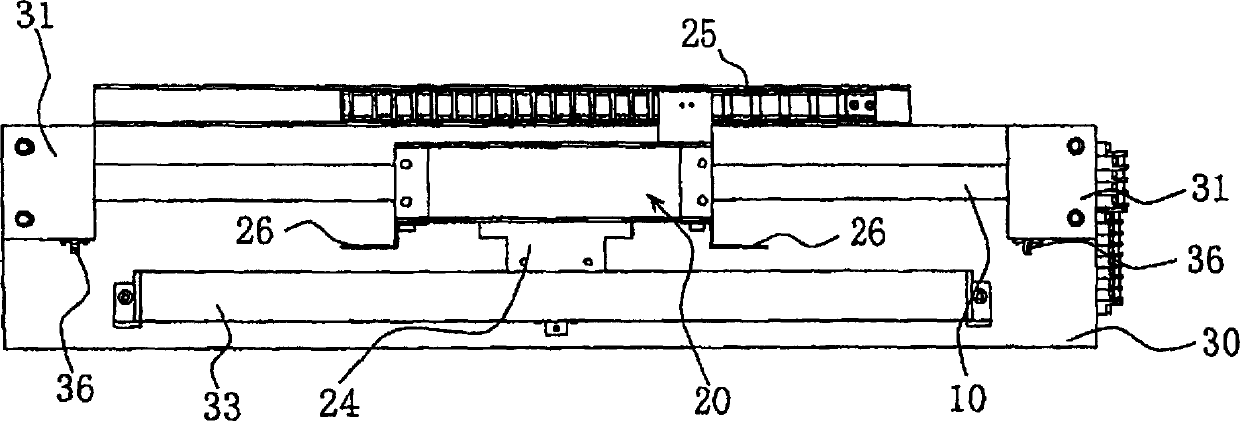

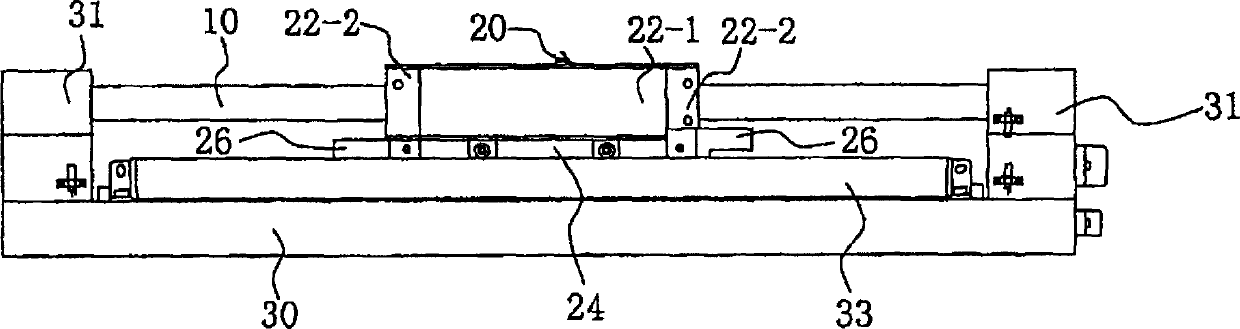

[0097] Hereinafter, the linear motor according to the first embodiment of the present invention will be described. Fig. 1 shows a schematic configuration of a linear motor, and Figs. 2a to 2d are diagrams of the linear motor viewed from four directions. That is, Fig. 2a is a plan view, Fig. 2b is a side view seen from the lower side of Fig. 2a, Fig. 2c is a side view seen from the upper side of Fig. 2a, and Fig. 2d is a view seen from the right side of Fig. 2a.

[0098] In Figs. 1, 2a to 2d, the linear motor includes: a shaft body (hereinafter referred to as a stator) 10 that houses a plurality of electromagnet coils (hereinafter referred to as coils) arranged in a row; A movable magnet body (hereinafter referred to as a mover) 20 that can move in the same direction as the extending direction of the stator 10 through the interaction. The stator 10 is installed between two brackets 31 fixed to the base 30 at a certain interval.

[0099] 3a and 3b again, the internal structure of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com