Electronic-control anti-backlash gear pair

A technology of gear pairs and gears, applied in the field of gear meshing pairs, can solve the problems of high control synchronization, complex structure and assembly, and relatively high requirements, so as to reduce the driving energy, the structure is simple, and the tooth flank can be eliminated or reduced. The effect of gap and hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

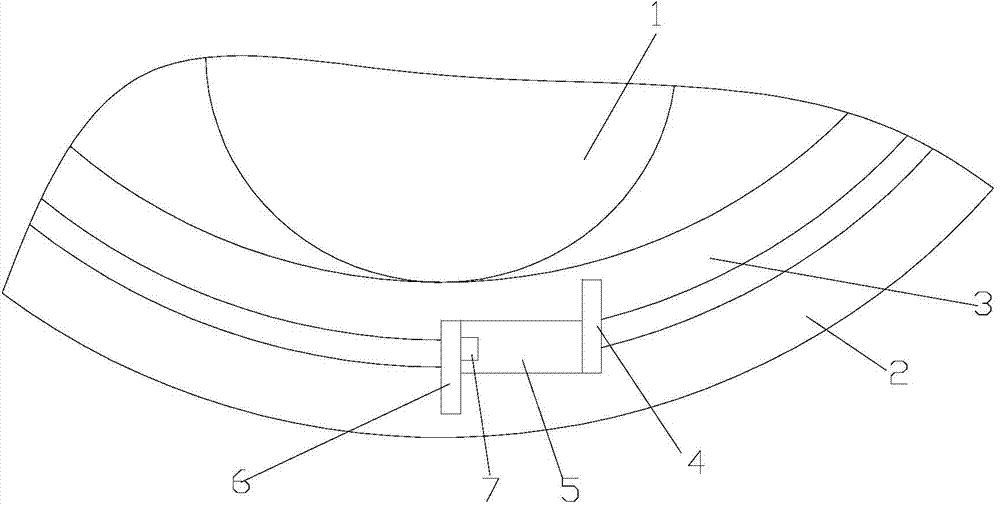

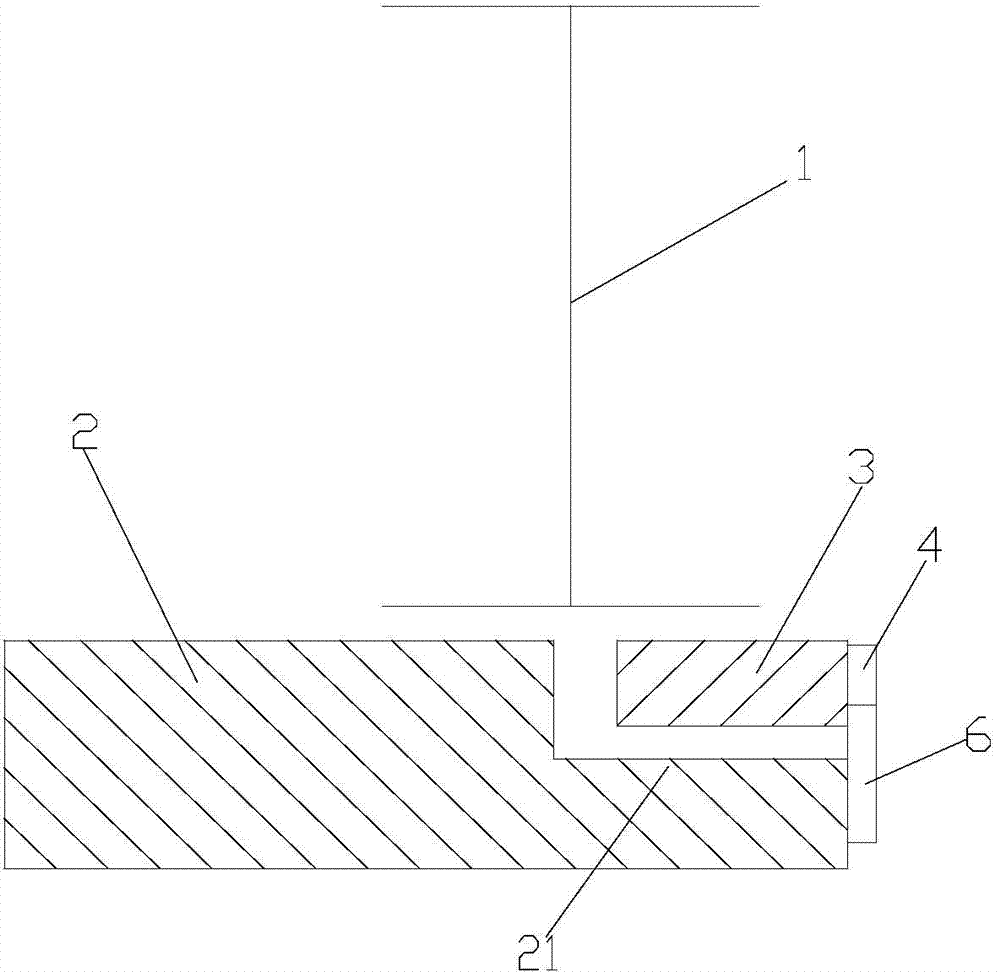

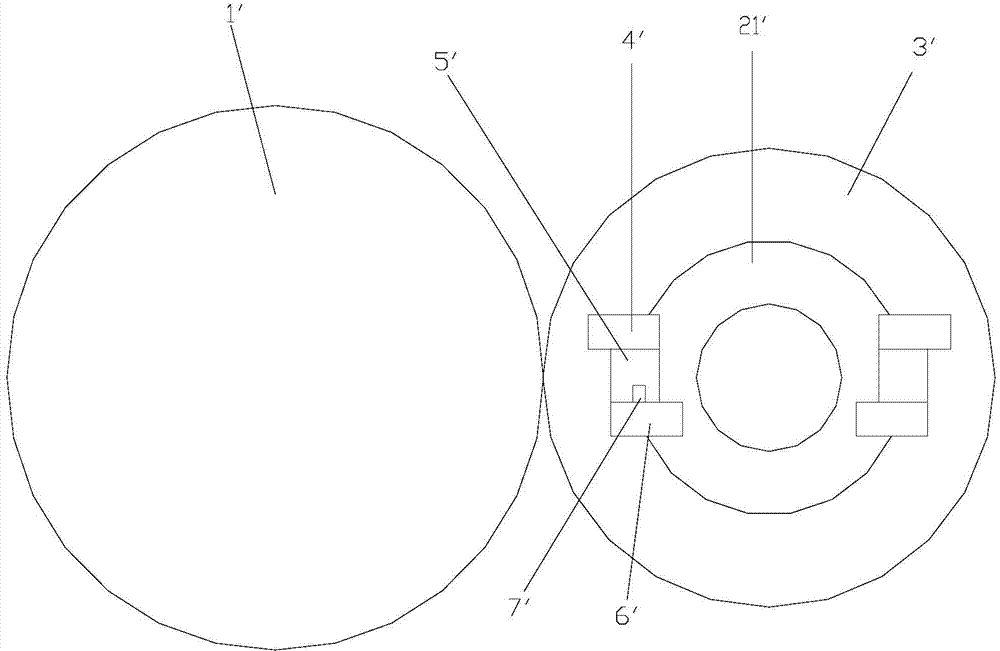

[0023] figure 1 It is a schematic diagram of the internal gear structure of the present invention, figure 2 for figure 1 Side view structural schematic diagram, image 3 It is a schematic diagram of the meshing structure of the external gear of the present invention, Figure 4 for image 3 Side view structural schematic diagram, Figure 5 It is a block diagram of the control principle, as shown in the figure: the electronically controlled backlash-eliminating gear pair in this embodiment includes gear I1, gear II2 and gear III3. The gear II2 and gear III3 are coaxially juxtaposed and mesh with gear I1, so The above-mentioned gear II2 and gear III3 have relative rotational degrees of freedom in the circumferential direction; that is, gear II2 and gear III3 constitute a double gear that meshes with gear I1, but there is a certain degree of rotational freedom between gear II2 and gear III3. Forming the possibility of mutual rotation to eliminate meshing backlash when backla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com