Anchor rod drawing device and method

A technology for pulling devices and bolts, which is applied in the installation of bolts, earthwork drilling, mining equipment, etc. It can solve the problems of insignificant increase in bolt pre-tightening force, broken and damaged bolts under high torque, and inability to meet on-site requirements. Requirements and other issues, to achieve rapid and effective tensioning, increase the pre-tightening force of the anchor bolt, and the effect of simple construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

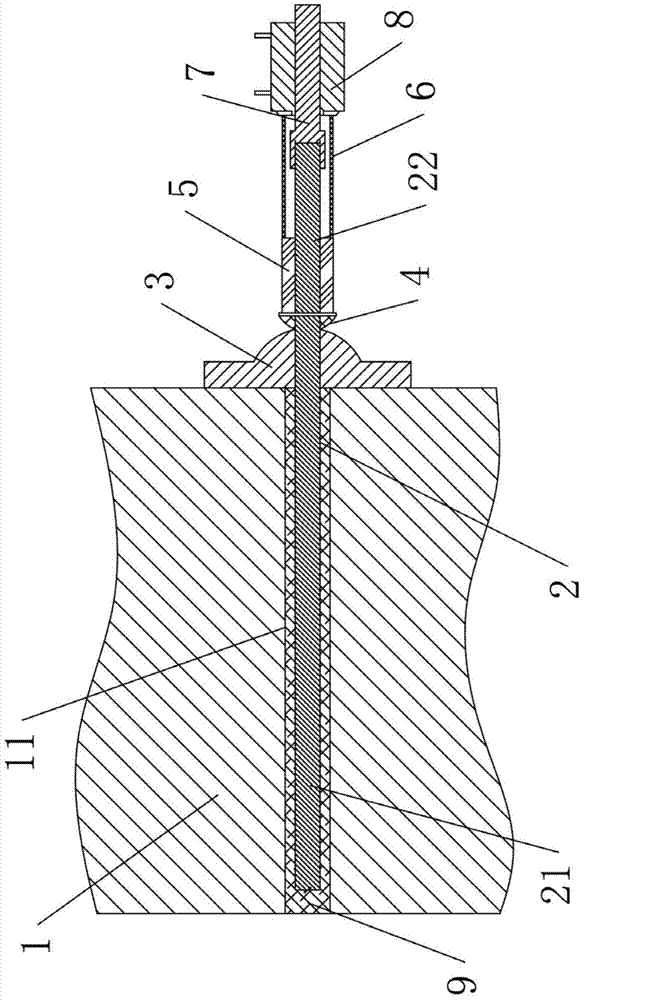

[0024] Reference figure 1 As shown, the anchor rod pulling device of the present invention includes: an anchor rod 2, a tray 3, a centering ball pad 4, a lock 5, and a tension mechanism 8; the anchor rod 2 includes an anchor rod 9 fixed to the coal rock mass 1 The anchor portion 21 in the bolt hole 11 and the vacant portion 22 exposed outside the bolt hole 11. The pallet 3 is fixedly installed on the coal rock body 1 through the bolt 2 and the lock 5. Specifically, the pallet 3 is installed at the outer port of the bolt hole 11 of the coal rock body 1, and the empty part 22 of the bolt 2 passes through the pallet 3. The lock 5 is installed on the vacant part 22 and pressed against the outside of the tray 3. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com