A sieve sleeve annulus sand flushing string

A technology for sand washing and pipe strings, which is applied in the field of sand washing pipe strings. It can solve the problems of cumbersome operation process, long sand washing operation cycle, and easy blockage of screen pipes, etc., and achieves simple construction steps, shortened operation cycle, and on-site operability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

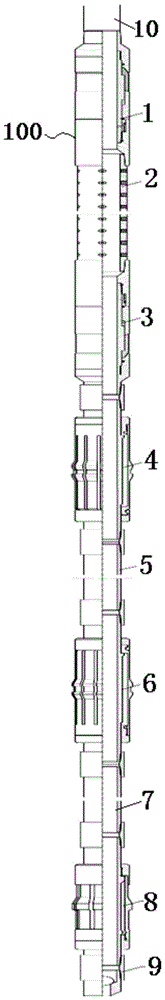

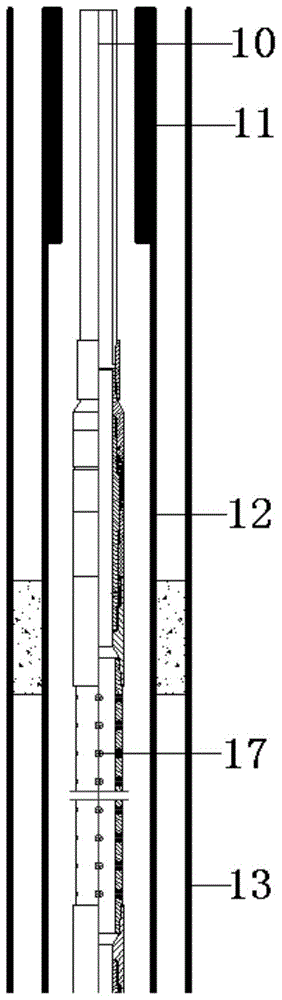

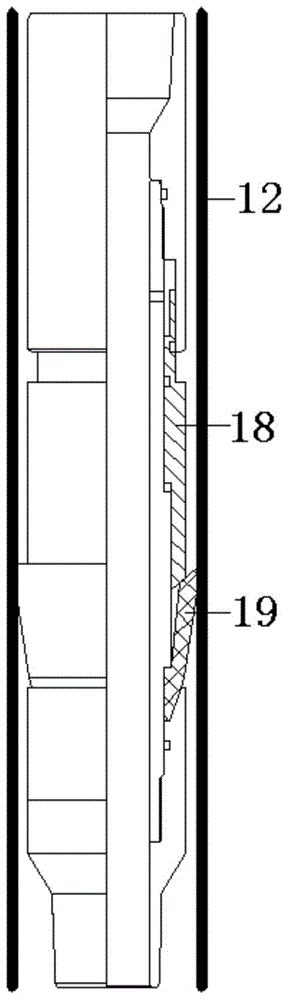

[0018] figure 1 The pipe string 100 provided by the present invention is shown, and the pipe string 100 includes an upper cup packer 1, a high-pressure sand flushing pipe 2, a lower cup packer 3, and a sliding sleeve closing tool from top to bottom 4. A sliding switch tool 6, a load indicator 8 and a check valve 9. The upper end of the upper cup packer 1 is tightly connected to the oil pipe 10 through the tubing buckle, and the lower end of the upper cup packer 1 is tightly connected to the upper end of the high-pressure sand washing pipe 2 through the tubing buckle. The lower end of the high-pressure sand washing pipe 2 is tightly connected to the upper end of the lower cup packer 3 through a tubing buckle, and the lower end of the lower cup packer 3 is tightly connected to the upper end of the sliding sleeve closing tool 4 . The lower end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com