Drill pipe water supply device

A technology for water supply device and drill pipe, which is applied to drill pipe, drill pipe, drilling equipment, etc., can solve the problems of inconvenient use of water supply joints and poor sealing performance of drill pipe, and achieve the effect of simple structure, solving sealing failure and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

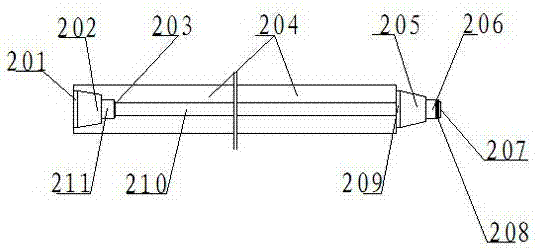

[0027] As shown in the figure, the specific implementation method is as follows:

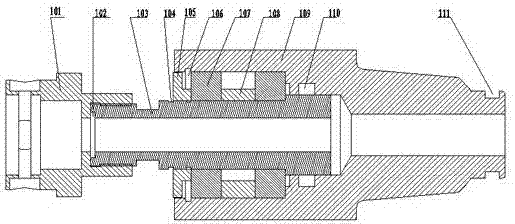

[0028] A drill pipe water supply device, including a water supply mechanism, a water supply joint 1 and a drill pipe 2, the drill pipe 2 is connected to the outlet of the water supply mechanism through the water supply joint 1, and the drill pipe 2 includes a plurality of sections with a hollow structure inside, The rod body includes a drilling section 204, a connecting head and a connecting seat at both ends of the drilling section 204, and the connecting head includes a tapered thread joint 205 provided with a tapered thread on the outer wall and the tapered thread joint 205 is connected to the drilling section The connection section I209 on 204, the connection seat includes a taper thread seat 202 with a taper thread hole and a connection section II201 matching with the connection section I209, and a raised section is provided on the other end of the taper thread joint 205 to form a sealed con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com