Novel pneumatic semi-automatic end-connection control method and device of rotor spinning machine

A technology of rotor spinning machine and control device, which is applied in spinning machine, open-end spinning machine, continuous winding spinning machine, etc. The quality of the wire connector, the low manufacturing cost, and the effect of improving the success rate of the connector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings:

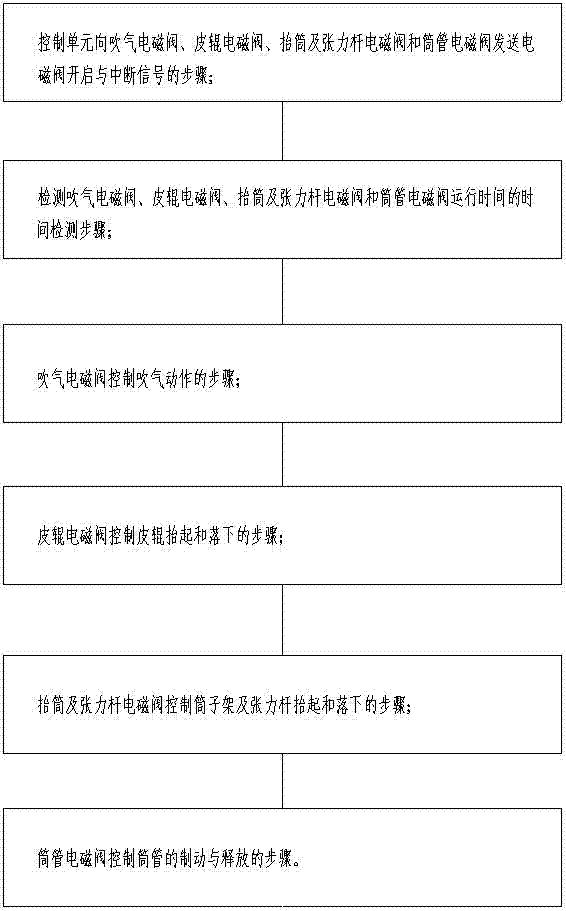

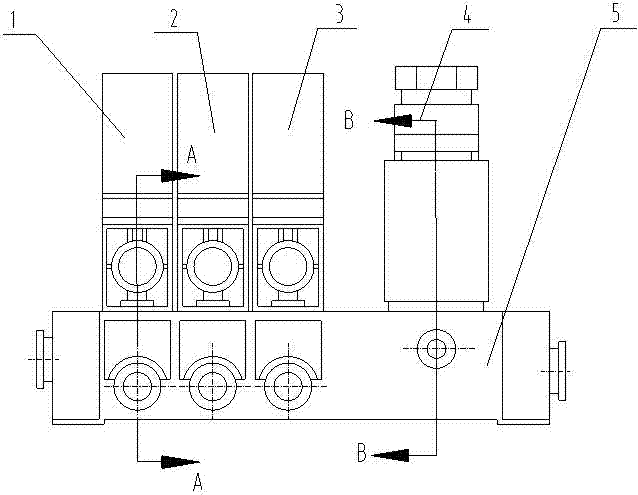

[0030] Such as figure 1 Shown is a step block diagram of a new type of pneumatic semi-automatic joint control method for a rotor spinning machine of the present invention. The method includes a control unit to blow solenoid valve 4, top roller solenoid valve 1, drum lift and tension rod solenoid valve 2 Steps of sending solenoid valve opening and interruption signals with the bobbin solenoid valve 3;

[0031] Time detection steps for detecting the running time of the air blowing solenoid valve 4, the top roller solenoid valve 1, the drum lift and tension rod solenoid valve 2, and the bobbin solenoid valve 3;

[0032] Steps of blowing solenoid valve 4 to control blowing action;

[0033] The top roller solenoid valve 1 controls the lifting and lowering steps of the top roller;

[0034] The lifting and tension rod solenoid valve 2 controls th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com