Vacuum furnace for sapphire crystal growth

A sapphire crystal and vacuum furnace technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve problems such as increasing the probability of thermal disturbance in the temperature field and instability, production difficulties, and crystal difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

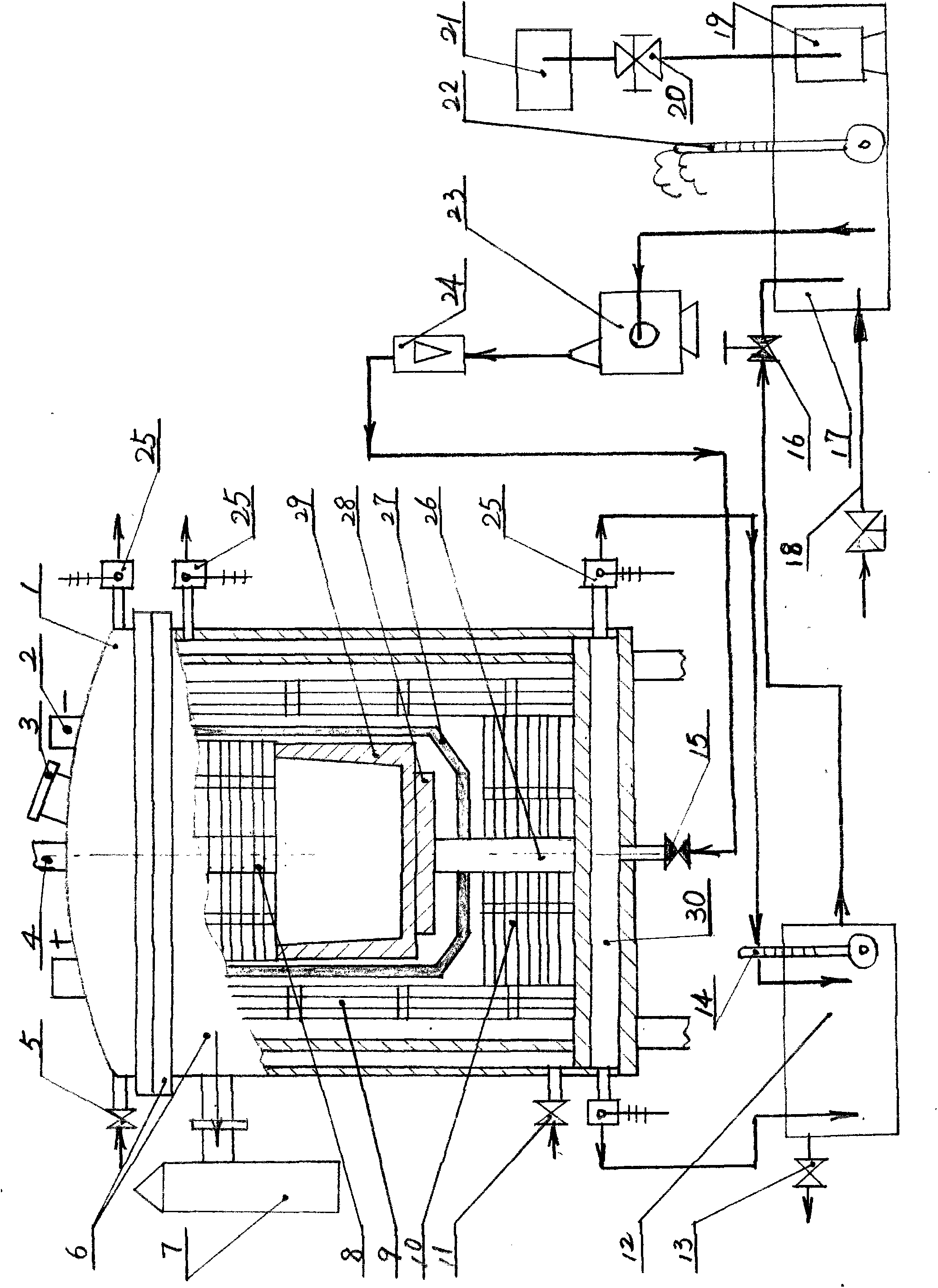

[0007] Referring to the accompanying drawings, it includes a body of furnace 6 with a double-layer structure, a water inlet valve 11 is arranged on the side wall of the body of furnace, a flow meter 25 is arranged on the water outlet of the side wall of the body of furnace, a vacuum system 7 is installed on one side of the body of furnace, and a vacuum system 7 is installed on one side of the body of furnace. There is a furnace cover 1 on the upper part of the furnace body, and there are water inlet valve 5, water outlet flow meter 25, electrode 2, observation hole 3, sapphire crystal pulling mechanism 4 on the furnace cover, and the furnace body has a lower heat shield 10, a side heat shield 9, On the upper heat shield 8, there is a crucible 29 in the center of the furnace body inside each heat shield, a heating element 27 outside the crucible, a crucible tray 28 below the crucible, and a tray top column 26 below the crucible tray, and the tray top column is placed on the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com