Sputtering device

A sputtering device and downstream technology, applied in sputtering plating, ion implantation plating, coating, etc., can solve problems such as deformation of long film substrates, surface panels that cannot be touched, poor appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

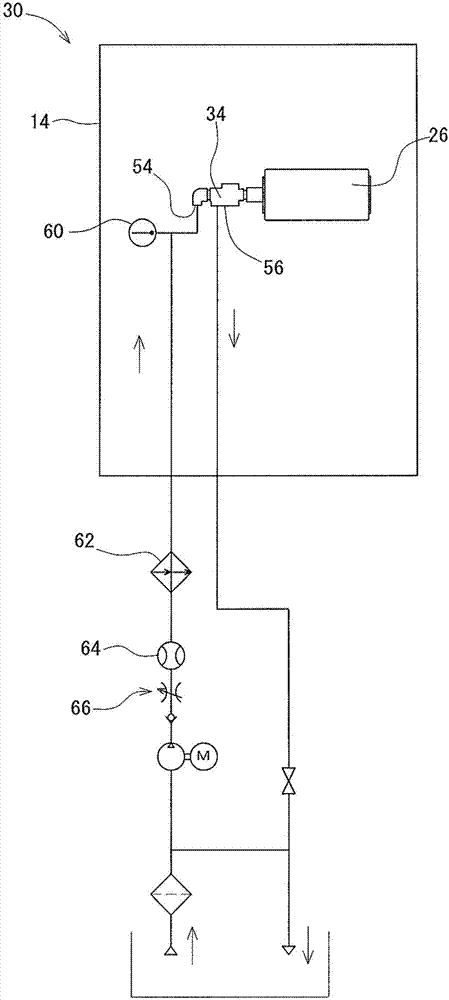

[0027] Next, embodiments of the present invention will be described in detail with reference to the drawings. exist figure 1 Among them, reference numeral 10 is the sputtering device of the present invention.

[0028] The sputtering device 10 is a device for forming a thin film on the surface of the elongated film substrate 16 conveyed along the surface of the film-forming roller 18, and the sputtering device 10 includes: a vacuum chamber 14; the above-mentioned film-forming roller 18, which Arranged in the vacuum chamber 14 in a rotatable manner; the target material 20, which is arranged in the vacuum chamber 14, is used to form a film-forming material on the surface of the elongated film substrate 16 conveyed along the surface of the film-forming roller 18 Gas supply mechanism 24, which is used to supply gas to the film-forming space 22 between the film-forming roller 18 and the target material 20; 3 driving rollers (downstream side conveying rollers) 26 (1), 26 (2), 26 ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com