Hot metal desulfurizer and its application

A technology for desulfurization of molten iron and vanadium titanomagnetite is applied in the field of molten iron smelting, which can solve the problems of high price, high use cost and prevent moisture absorption, and achieve the effects of good slag state, safe use and easy slag removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with embodiment the present invention is further described. However, the protection scope of the present invention is not limited to the scope of the embodiments.

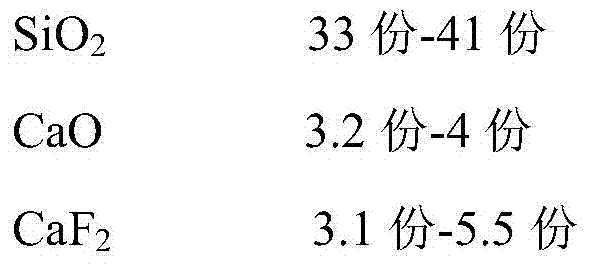

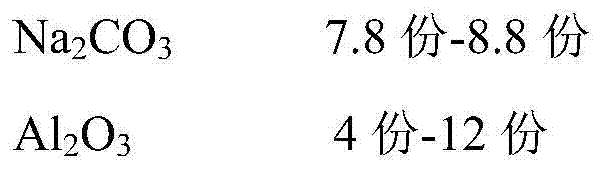

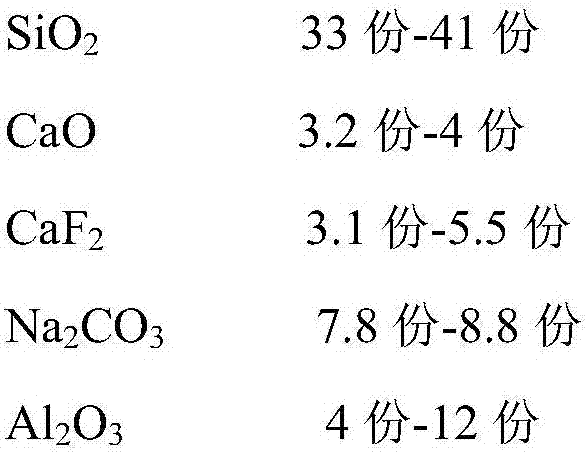

[0030] Table 1 Ratio of molten iron desulfurizer

[0031] raw material name

chemical components

Example 1

Example 2

Example 3

Quartz sand

SiO 2 55%

60

67

75

quicklime

CaO40%

10

9

8

fluorite

CaF 2 78%

6

7

4

soda ash

Na 2 CO 3 98%

9

9

8

Aluminum oxide

Al 2 o 3 80%

15

8

5

[0032] The ratio of raw materials in Table 1 is the mass fraction.

[0033] The raw materials were weighed according to the ratio of raw materials in Table 1, crushed to a particle size of ≤1 mm, and mixed to obtain the molten iron desulfurizers of Examples 1, 2, and 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com