Method for producing conductive coating liquid composition having electromagnetic wave shielding function

A manufacturing method and a conductive technology, applied in a field, can solve the problems of high raw material prices, rising prices, excessive consumption of process costs, etc., and achieve the effects of consuming process costs, excellent productivity, and excellent alcohol solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1~3

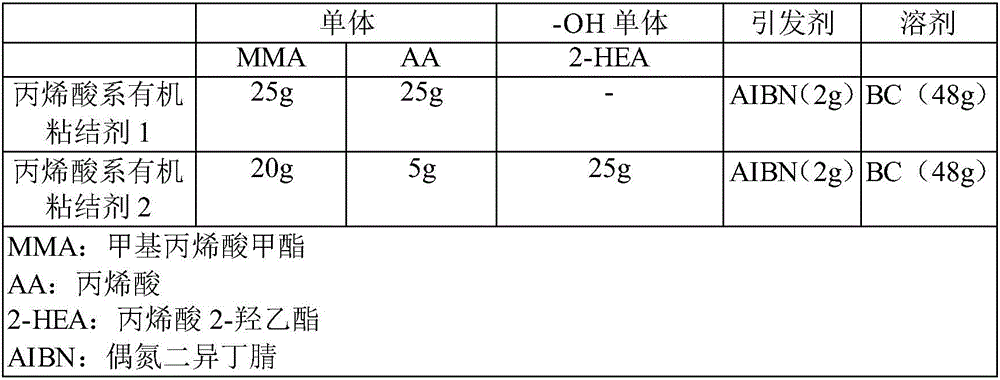

[0105] Solvents (first solvent and second solvent) and inorganic adhesive agent, and stirred at a speed of 1000 rpm for 40 minutes to completely mix the acrylic organic binder and inorganic binder with the solvent. While continuing to stir, drop the PEDOT / PSS conductive polymer aqueous dispersion at a rate of 5 g / min, and finally add the surface adjustment additive and mix uniformly for about 1 hour at a rate of 1000 rpm To prepare the coating liquid composition.

[0106] Table 2

[0107]

[0108]

[0109] The conductive coating liquid composition produced according to Example 1 to Example 3 and the coating liquid composition produced according to Comparative Example 1 to Comparative Example 3 were passed through #20 (number) bar coating (Bar coating) (wet (Thickness of coating film of wet): 45 μm) After coating on one surface of transparent soda lime glass (0.7mm, NSG company), harden in a hot air drying oven at 100°C for 5 minutes to completely remove water and solven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com