Vacuum glass air-exhaust port and manufacturing method thereof

A technology of vacuum glass and air suction port, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc., and can solve problems such as low production efficiency, weakened solder performance, airtightness, and feasibility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

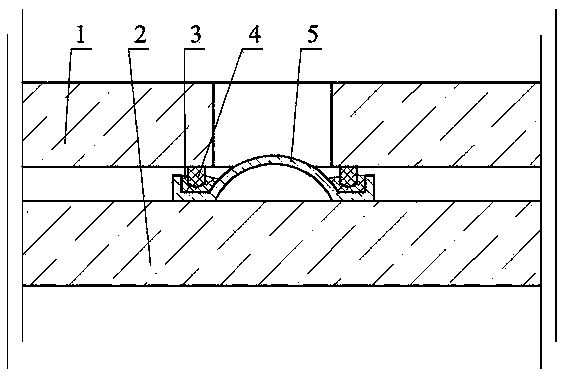

[0077] Example 1: see figure 1 , The vacuum glass is composed of upper glass 1 and lower glass 2. A through hole is drilled on the upper glass 1 to form an air extraction port, and the glass paste or metal paste is printed on the lower surface of the upper glass 1 by mechanical coating or printing technology A sealing ring concentric with the suction opening is placed on the upper surface of the lower glass 2 and a sealing box 5 concentric with the suction opening is placed. The sealing box 5 is a metal box with a raised bottom, which can be fixed on the lower glass 2 by bonding. The sealing ring 4 of the upper glass 1 can be inserted into the sealing box 5, and there is an air extraction channel between the sealing ring 4 and the sealing box 5; the upper glass is sent into a high-temperature furnace or a tempering furnace to sinter the sealing ring on the upper glass, and then used The low-temperature glass solder is used to seal the upper and lower glass sheets after being com...

Embodiment 2

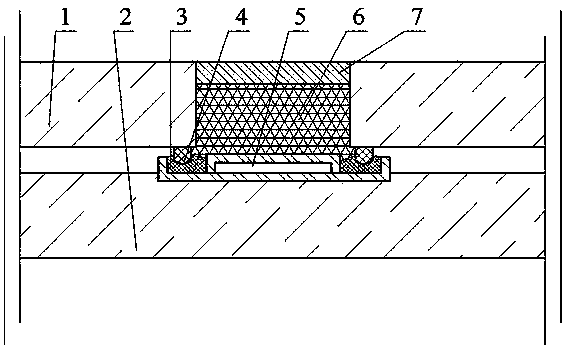

[0078] Example 2: see figure 2 , Drill a through hole on the upper glass 1 to form an air extraction port, and use glass paste or metal paste to bond a metal ring or glass ring on the lower surface of the upper glass 1. When a metal ring is used, it is preferably close to the glass thermal expansion coefficient Metal such as Kovar alloy. When glass rings are used, metal paste is preferably applied to strengthen the sealing effect; a pit is opened on the upper surface of the lower glass 2 at a position corresponding to the suction port, and the sealed box 5 is placed in the pit, The sealed box 5 is two large and small glass boxes. The inner surface of the large glass box is coated with metal paste, and the two glass boxes are sintered together by high temperature; the sealing ring 4 of the upper glass 1 can be inserted into the two sealed boxes 5 The upper glass is sent into a high temperature furnace or a tempering furnace to sinter the sealing ring on the upper glass, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com