Flip bracket for maintenance of axle differential

A technology for flipping brackets and differentials, which is applied to lifting devices, workbenches, manufacturing tools, etc., can solve problems such as inconvenient maintenance, flipping and assembly, complex structure, and affecting maintenance effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

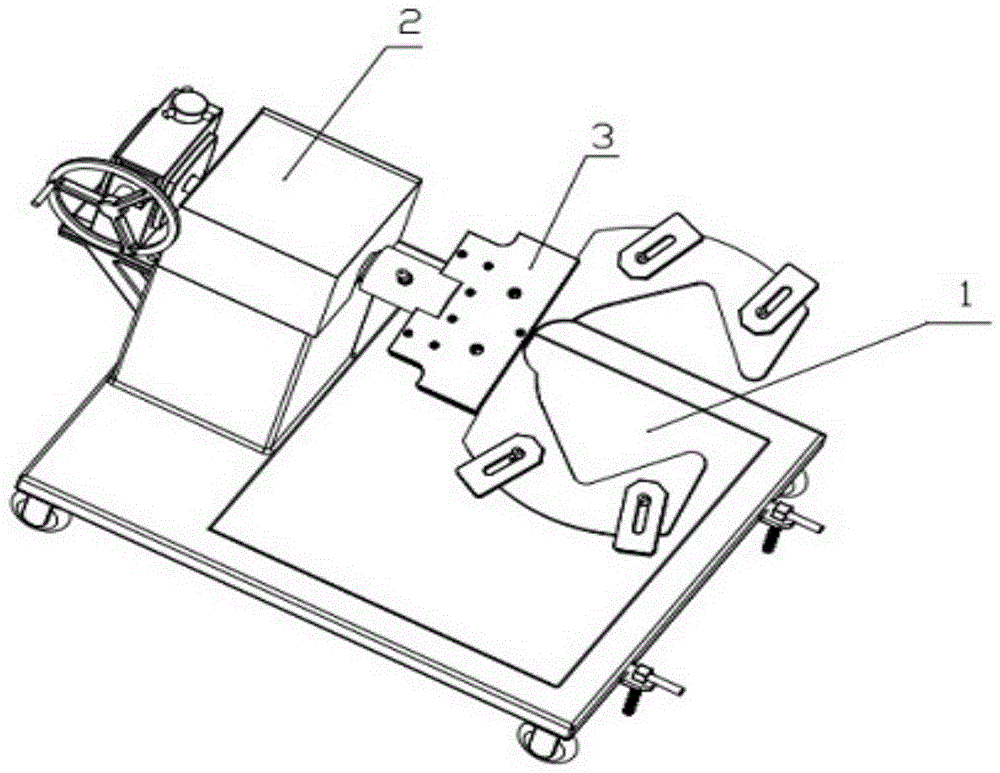

[0013] 1. Refer to figure 1 , figure 2 , image 3 , Figure 4 , a vehicle axle differential maintenance overturn bracket in the present embodiment includes: frame 1, overturn beam 2, clamping device 3 and several bolts, the upper bearing bracket 102 in the frame 1 and the speed reducer in the overturn beam 2 202 is connected and fixed with bolts, and the clamping device 3 and the overturning beam 2 are connected with a bolt 305 .

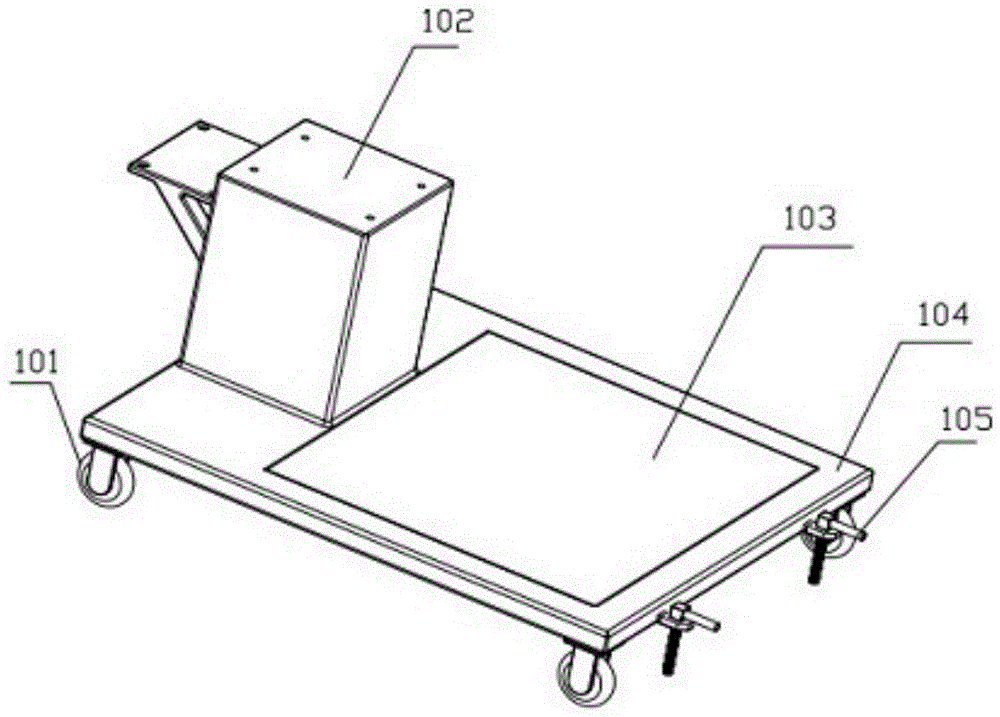

[0014] 2. Refer to figure 2 , frame 1 is made up of universal wheel 101, cover plate 103, vehicle frame 104, adjustment support wrench 105, wherein the universal wheel 101 is fixed with vehicle frame 104 by bolt connection, and adjustment support wrench 105 is fixed with vehicle frame 104 by screw connection , and can ensure that the adjustment support wrench 105 is in operation to prevent the universal wheel 101 from being crushed, and the cover plate 103 is covered on the vehicle frame 104 .

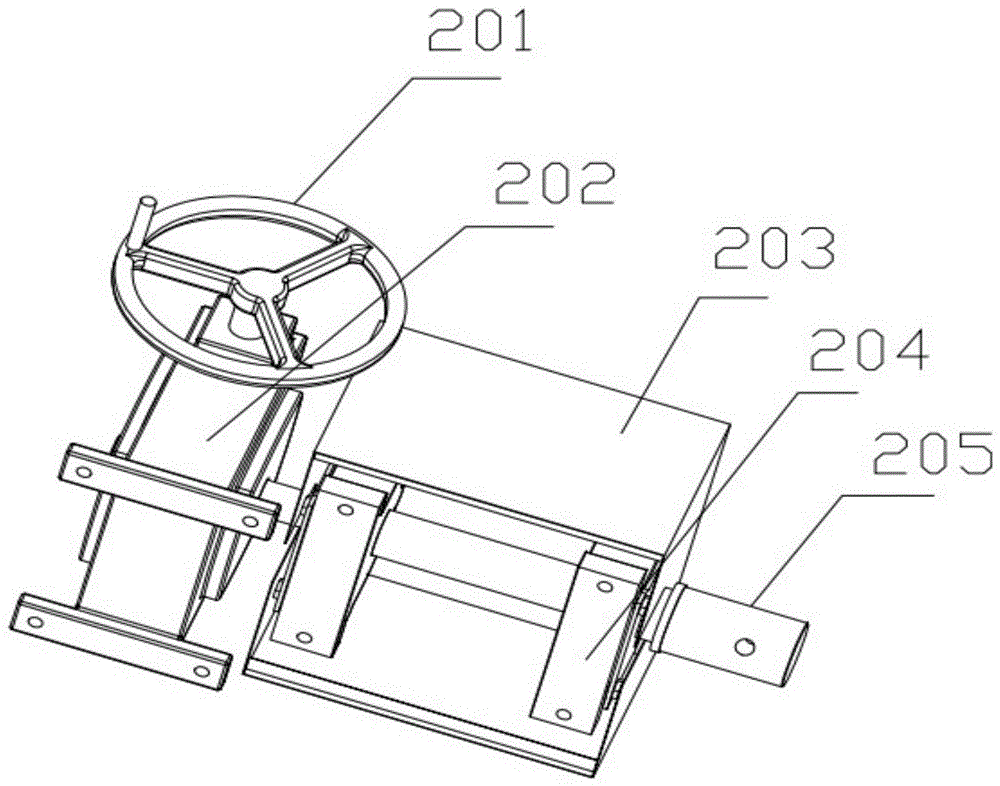

[0015] 3. Refer to image 3 , the overturning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com