Ink supply system for tire numeric printer

A printer and ink supply technology, applied in printing and other directions, can solve problems such as hose not feeding ink, test line disconnection, large ink leakage spots, etc., to reduce chip contact pin deformation, safe and convenient use, and high-quality printing quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

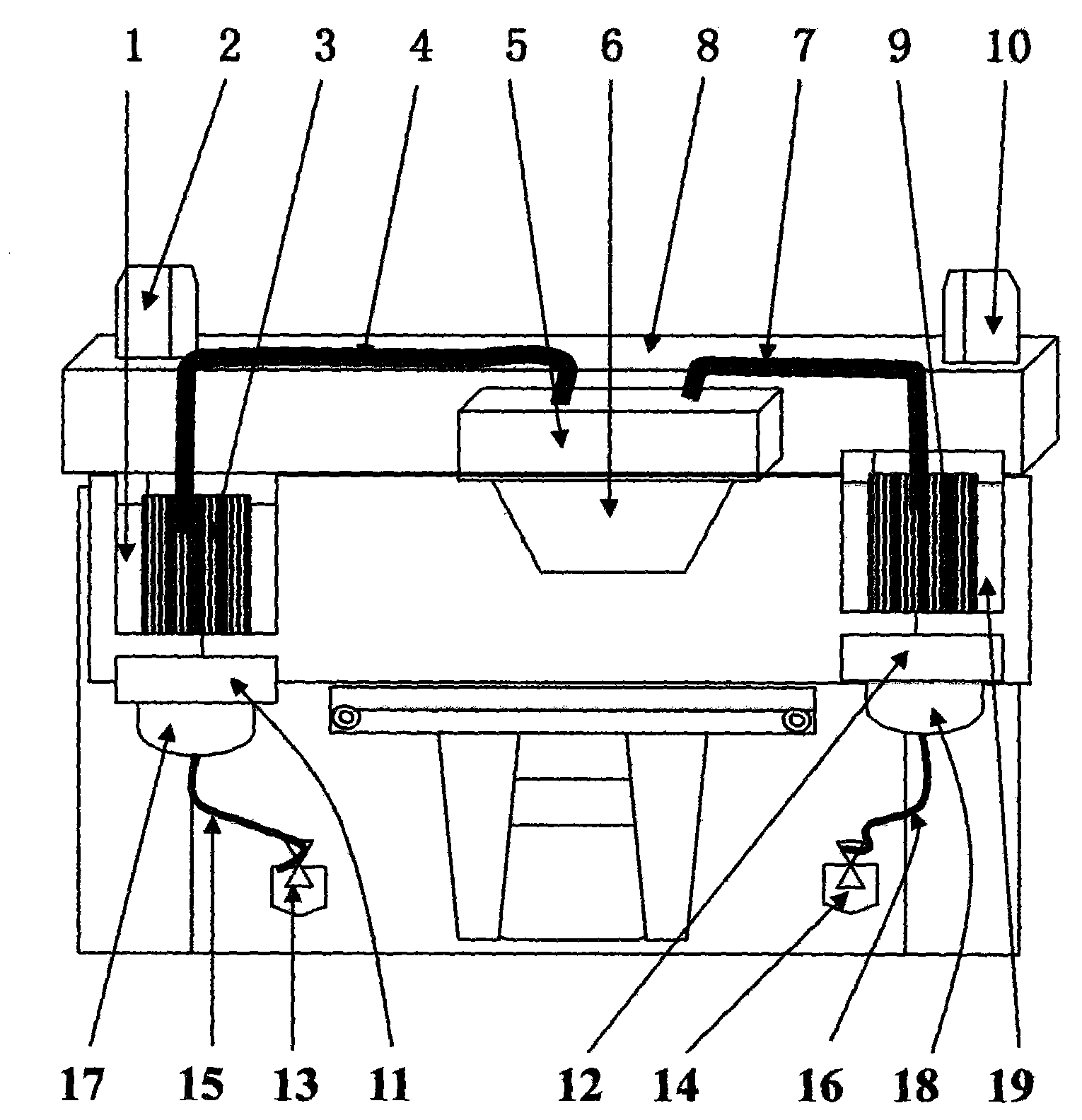

[0018] refer to figure 1 , an ink supply system for tire digital printers of the present invention adopts the following technical scheme: it is characterized in that: the printing pressure chamber 5 is provided with a printing nozzle 6 at the lower end, and the printing pressure chamber 5 is connected to the left ink supply pipe 4 through the left ink supply pipe 4. In the ink container 3, the upper end of the ink sleeve 1 of the left ink supply device is provided with a left ink exhaust chamber 2, and the lower end of the left ink supply device 3 is correspondingly provided with a left ink washing scraper 11, and the lower end of the left ink washing scraper 11 is connected to the left nozzle cleaner 17 The print head 6 is cleaned and waste ink is sucked by the left ink sucker 13 through the left waste ink suction pipe 15 .

[0019] The printing pressure chamber 5 is provided with a right ink supply pipe 7 connected to the right ink supply device 9, the upper end of the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com