An anti-flying bag device in the production process of plastic bags

A production process, anti-flying bag technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of cluttering the production line, easy to fly, etc., to achieve practical and simple, prevent disorder, smooth and orderly continuous production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

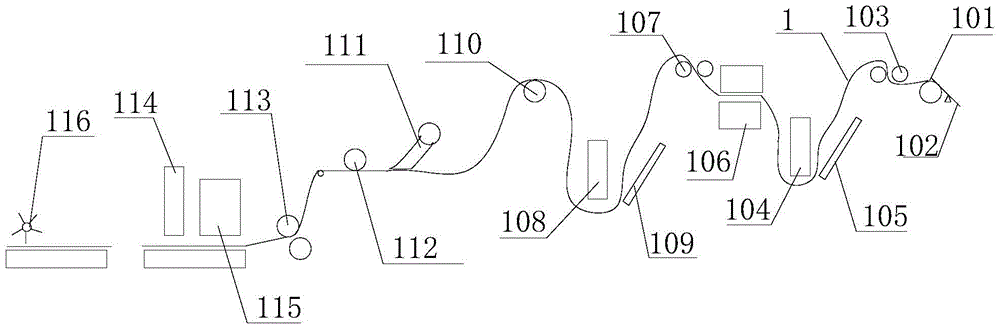

[0023] Such as figure 1 As shown, this embodiment includes the following steps:

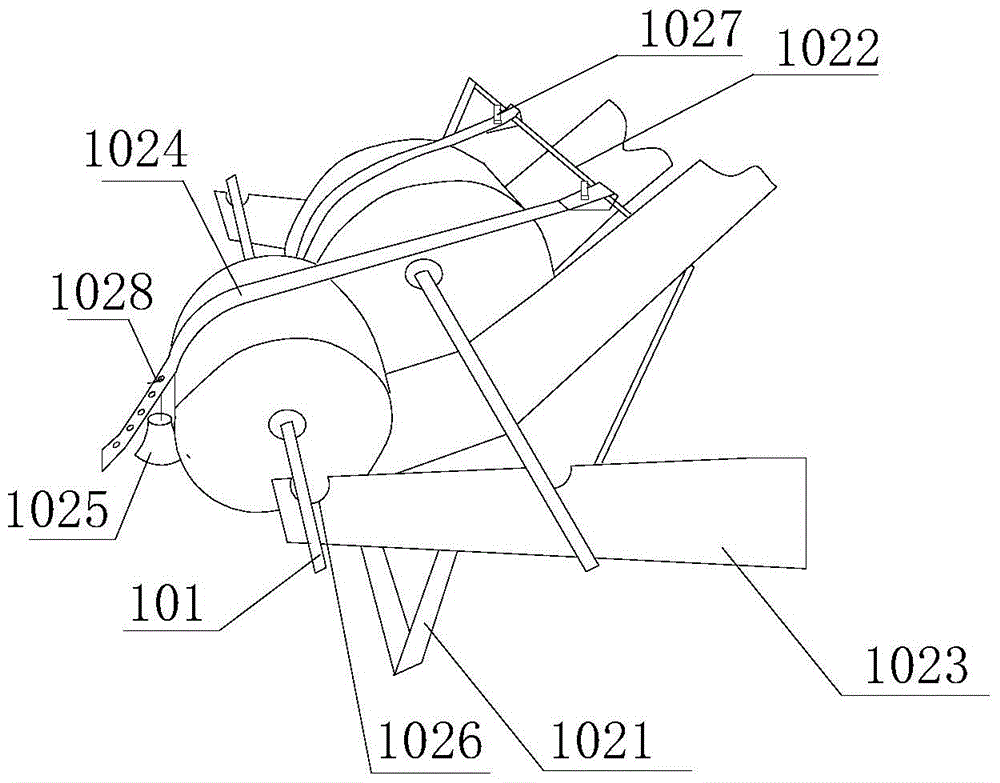

[0024] (1) Winding the blow-molded plastic film 1 on the discharge roller, pressing the plastic film 1 on the discharge roller, and discharging it after being leveled by the first material roller;

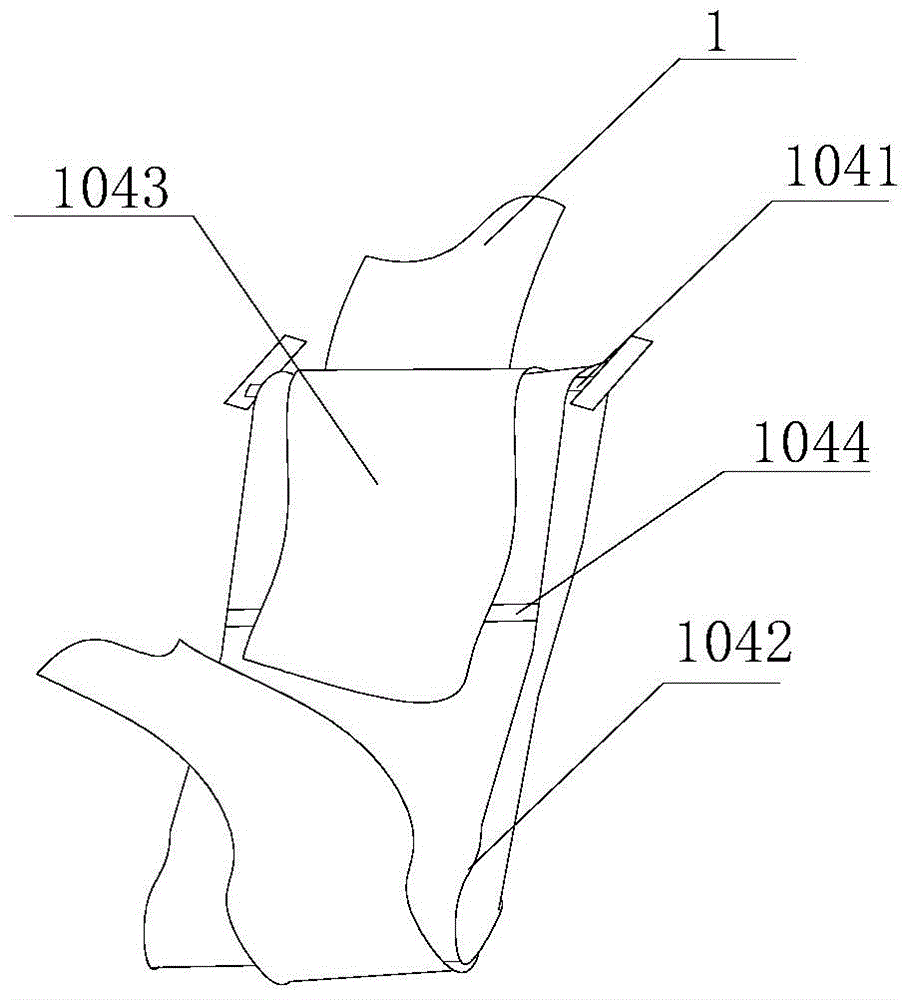

[0025] (2) Remove static electricity to plastic film 1, prevent plastic film 1 from swinging when removing static electricity, carry out edge sealing after removing static electricity, the plastic film 1 after edge sealing is a plurality of continuous plastic bags; If color printing is required, after edge sealing The plastic film 1 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com