A Pneumatic Gripper Device with Rotatable Product Position

A gripper device and attitude technology, applied in the directions of manipulators, manufacturing tools, chucks, etc., can solve the problems of not adapting to the connection requirements of automated production lines, single function, only clamping and grasping, loosening and releasing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

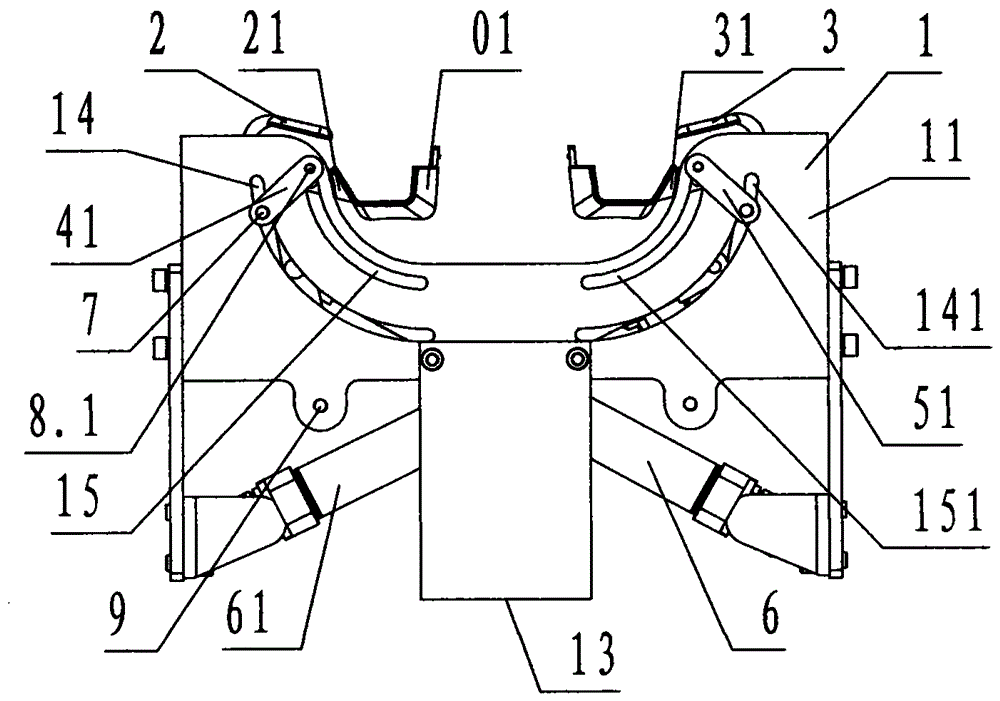

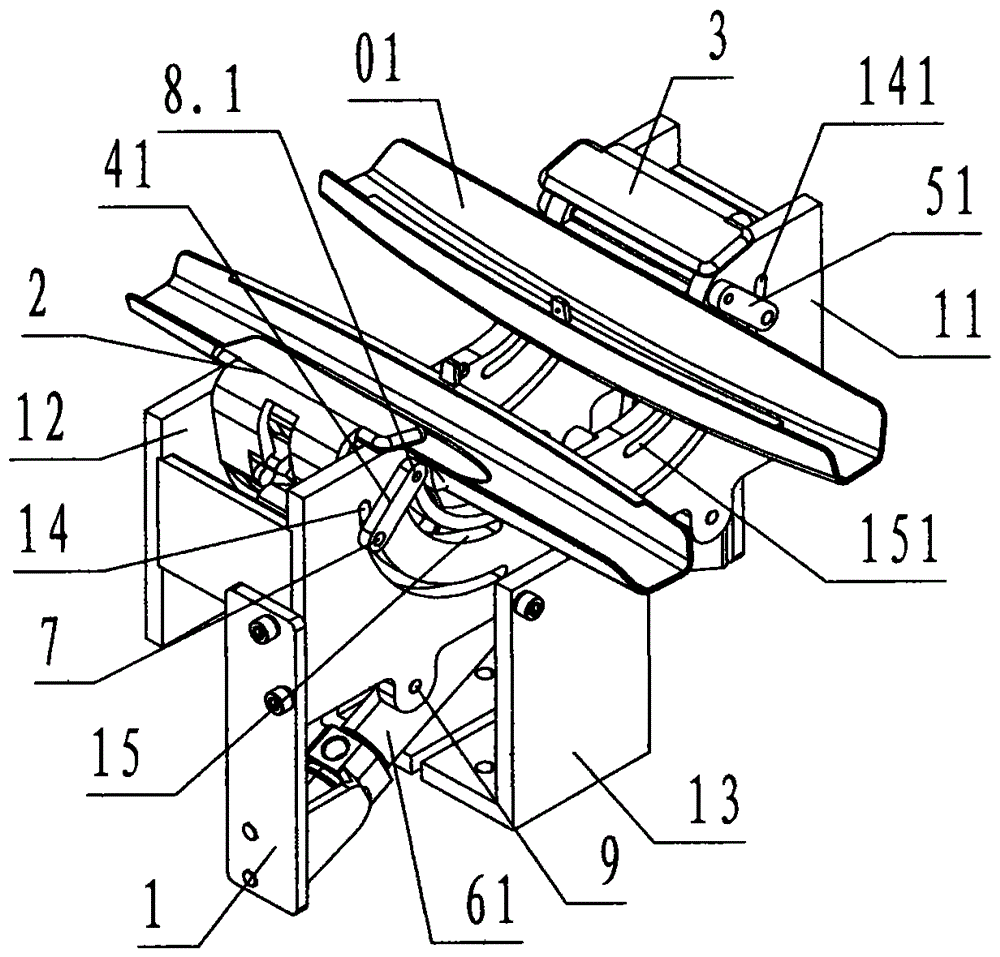

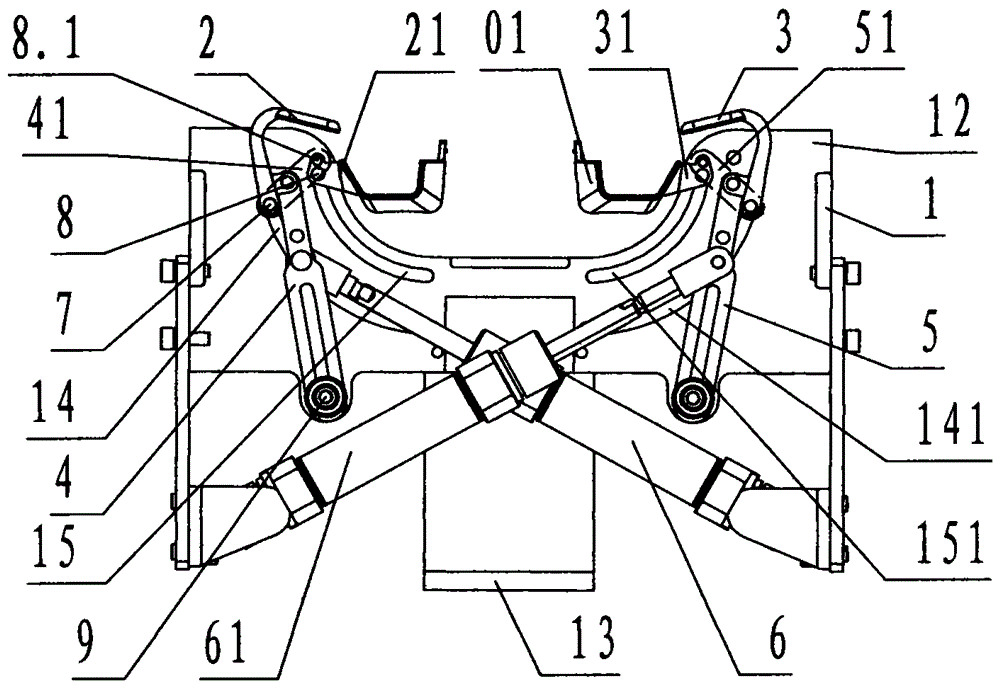

[0028] refer to Figure 1 to Figure 7, a pneumatic gripper device with a rotatable product posture according to the present invention, comprising a base 1, an upper left sliding claw 2, a left sliding claw 21, an upper right sliding claw 3, a right sliding claw 31, a left upper claw connecting rod 4, a left lower claw connecting rod Rod 41, right upper claw connecting rod 5, right lower claw connecting rod 51, left cylinder 6, right cylinder 61, upper rotating shaft 7, lower rotating shaft 8, lower moving shaft 8.1, guide shaft 9, wherein: described base 1 is A rectangular frame-shaped steel member with an open top and a bottom bottom surrounded by steel plates, the bottom wall below the center of the base 1 is called the connecting frame 13; the front and rear walls of the base 1 are called the front wall 11 respectively And the rear wallboard 12; the middle and upper part of the rear wallboard 12 is provided with a rectangular through groove called an avoidance groove, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com