Centering clamp

A technology of centering fixture and clamping body, applied in the field of tooling fixture, can solve the problems of inability to meet the machining accuracy, inability to center the workpiece, poor centering accuracy, etc., and achieve convenient and quick pressure regulation, high centering accuracy and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

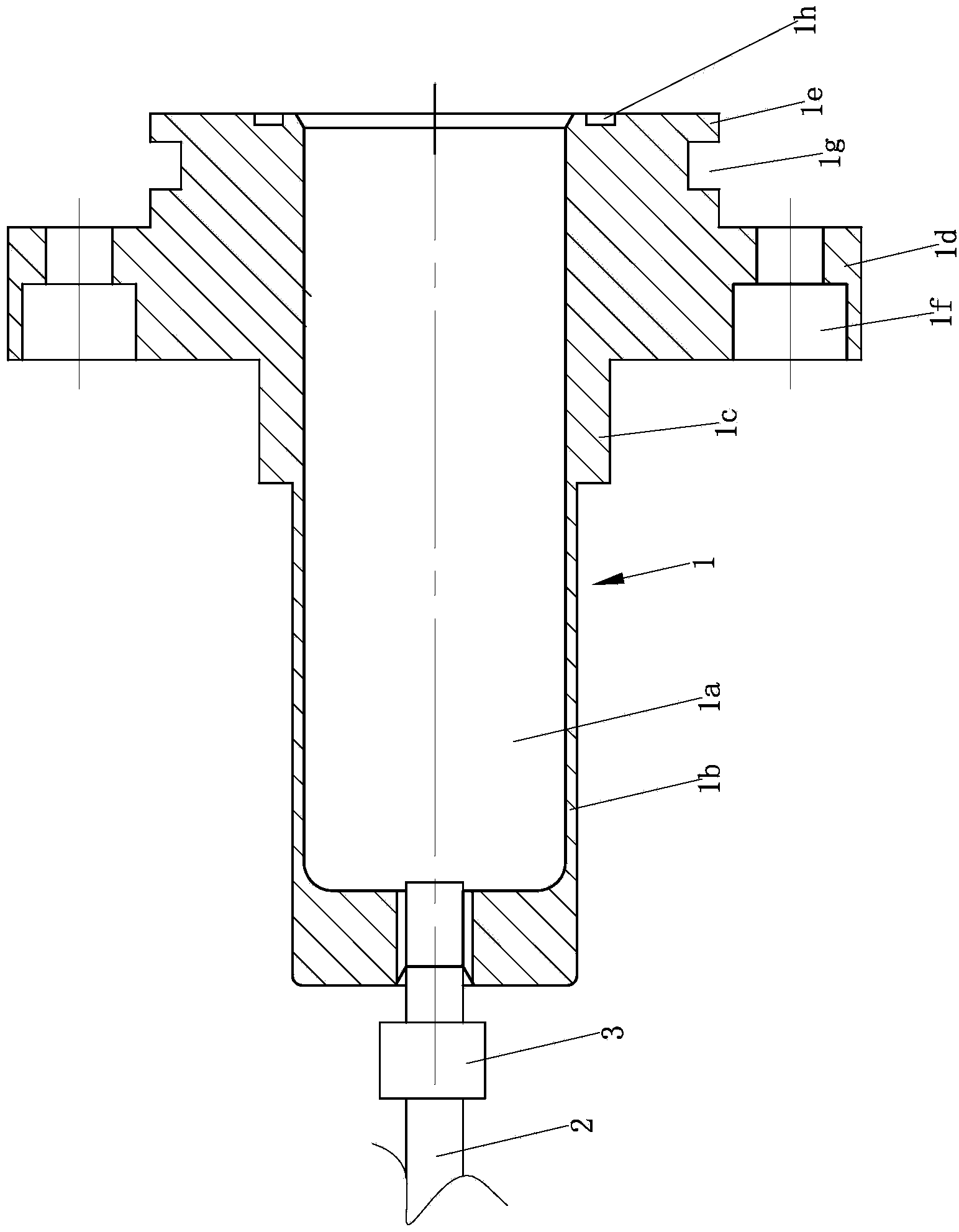

[0012] like figure 1 As shown, a centering fixture is mainly composed of a clamp body 1 , a pressure relief pipe 2 and a pressure relief valve 3 . Wherein, the material of clamp body 1 is spring steel, and the central hole 1a of this clamp body 1 is a two-section combination hole, and is formed by connecting the threaded hole section on the left and the oil injection hole section on the right, and the diameter of the oil injection hole section is larger than The diameter of the threaded hole segment. The oil inlet end of the pressure relief pipe 2 is connected to the threaded hole section of the central hole 1a of the clamp body 1, a pressure relief valve 3 is installed on the pressure relief pipe, and a hydraulic pump may be provided at the oil outlet end of the pressure relief pipe 2 connected.

[0013] The clamp body 1 is a four-stage stepped shaft stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com