A hand-held expansion sleeve centering shaving fixture

A hand-held, expanding sleeve technology, which is applied in the direction of gear teeth, gear cutting machines, manufacturing tools, etc., can solve the problems of difficult removal and removal of workpieces, heavy weight, and high precision requirements for positioning aperture dimensions, and achieve improved tooth shape accuracy, reliable positioning, effective centering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

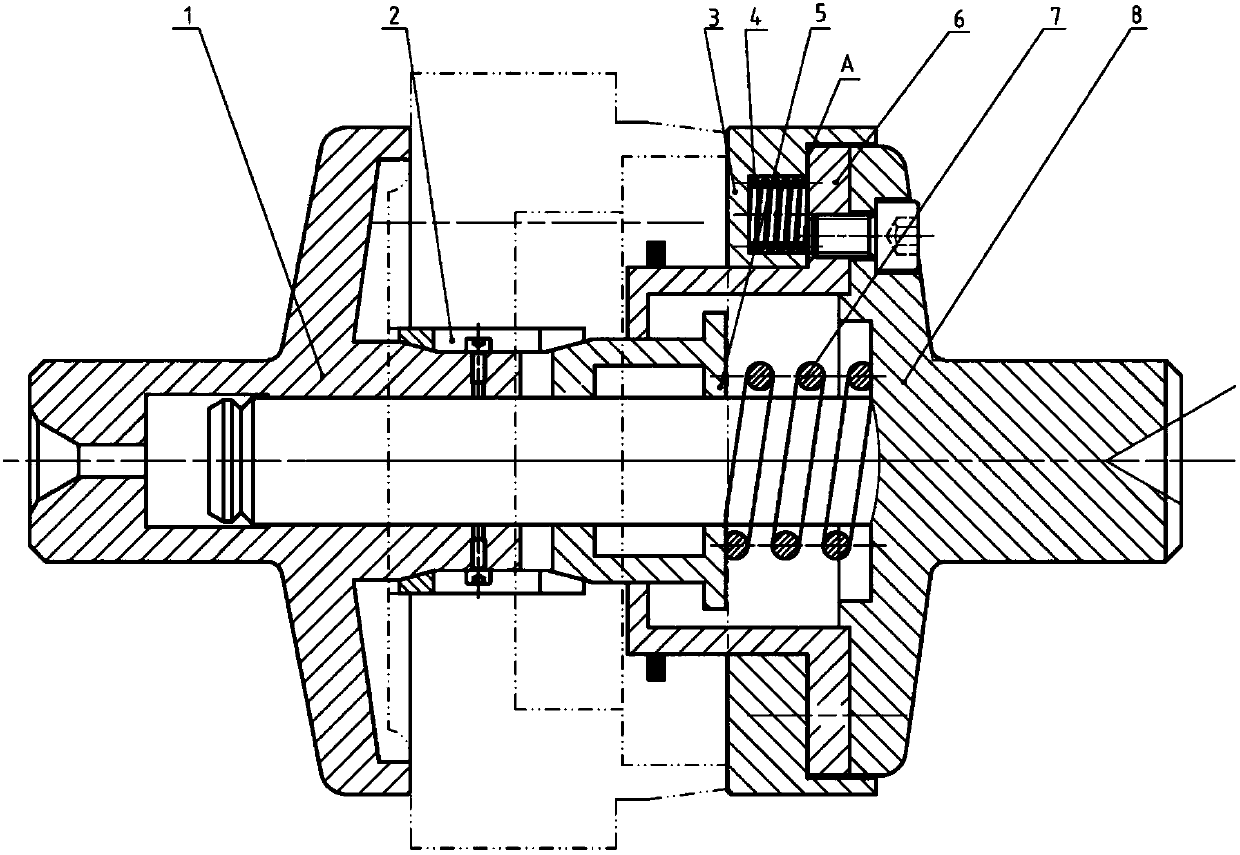

[0019] The present invention is a hand-held expansion sleeve centering gear shaving fixture, such as figure 1 As shown, the static pressure plate 1 and the mandrel 8 cooperate with the left and right tops of the gear shaving machine; the double-cone expansion sleeve 2 connected to the positioning tube cooperates with the static pressure plate 1 and the expansion sleeve gland 5 through the inner cone surface , to tighten the workpiece, the workpiece is indicated by a dotted line in the figure; the static pressure plate 1 and the mandrel 8 are the clearance fit of the hole shaft to ensure that the fixture is concentric with the left and right top of the machine tool; the hanging sleeve 6 and the expansion sleeve gland 5 are the clearance fit of the bore shaft, It plays a position-limiting role;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com