Head-mounted display lens assembly testing machine

A technology of lens components and testing machines, which is applied in the direction of testing optical performance, etc., and can solve problems such as the lack of a unified industry standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

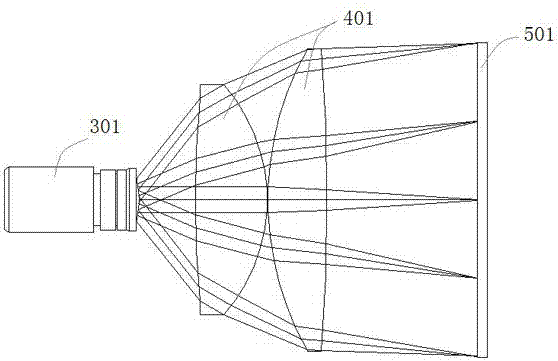

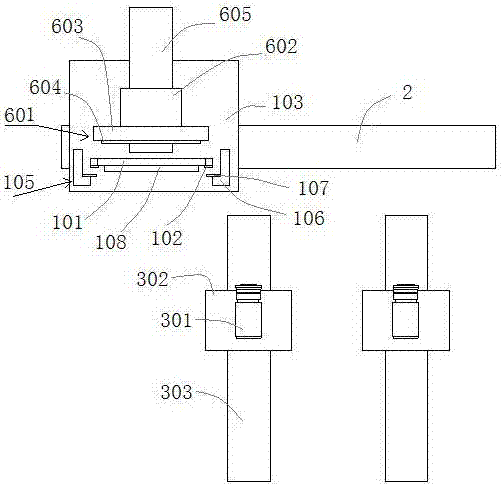

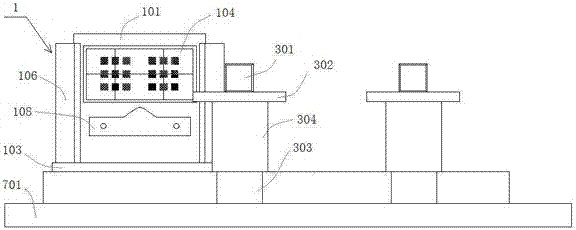

[0027] Embodiment 1, a head-mounted display lens assembly testing machine of this embodiment, its principle is as follows figure 1 As shown, the image receiving device 301 is set at the position of the human eye, instead of the human eye, the image imaged on the display 501 is received through the lens assembly 401, and the image is taken, so that the head-mounted display can be analyzed by analyzing the image in the later stage. Information about lens components. Such as Figure 2-Figure 3 As shown, it is a top view of the head-mounted display lens assembly testing machine proposed in this embodiment, which includes a clamping part 1 for fixing and supporting the lens assembly, and is used to drive the clamping part 1 along the horizontal plane with the lens. The first driving mechanism 2 that moves in the direction perpendicular to the optical axis of the component, and the image receiving device 301 arranged on one side of the clamping part 1, such as image 3 As shown, i...

Embodiment 2

[0036] Embodiment 2, a head-mounted display lens assembly testing machine of this embodiment is suitable for aligning the best back focus of the lens assembly. On the one hand, it can guide the installation of the display and the lens assembly of the head-mounted display. On the other hand, it can It is used to test the best back focus of the left eye and the right eye respectively, and judge whether the error of the best back focus of the two is within the allowable range, so as to verify whether the product is qualified. Since it is not necessary to be fixed on the clamping part 1 together with the display and the lens assembly, as figure 2 As shown, only the display unit 601 needs to be provided on the opposite side of the clamping part 1 to the image receiving device 301 for imaging by simulating a display. The display unit 601 is arranged on the first substrate 103, the display unit 601 is arranged on the other side of the clamping part 1, and is arranged on the first su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com