Drive clutch self-priming device

A technology of self-priming device and separation device, applied in the direction of driving pump, pump device, machine/engine, etc., can solve the problems of unfavorable pump mass production motor after-sales maintenance, user disapproval, and many preparations, etc., to achieve convenient standardized design and Simple and reliable production, control elements, and simple flow regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

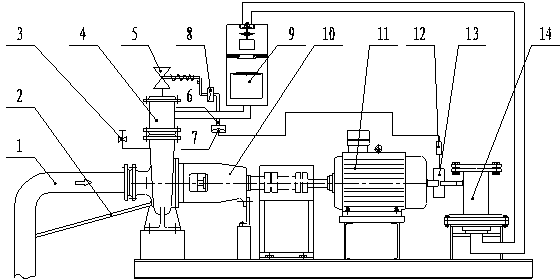

[0016] The concrete implementation of the present invention will be further described below in conjunction with accompanying drawing:

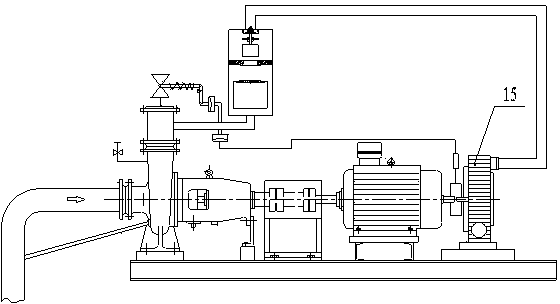

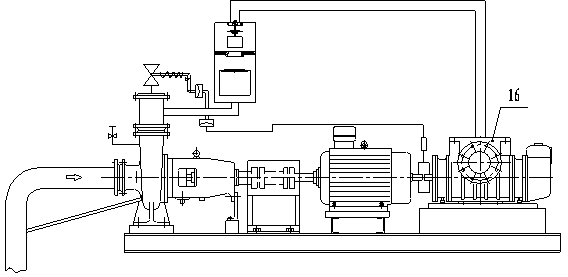

[0017] attached by figure 1 It can be seen that the self-priming device adopts a double-shaft motor, and there is a shaft at the front and rear ends of the motor. The front shaft of the motor drives the centrifugal pump 10, and the rear shaft is connected to the clutch 13 and drives the vacuum device to vacuum, wherein the vacuum device includes a diaphragm type vacuum device. 12. Various vacuuming equipment including gas ring vacuum pump 13 and Roots pump 14. There are two ways of driving between the motor shaft and the vacuum device: the clutch is directly mounted on the motor shaft to drive the vacuum device or the motor is connected to the clutch through a coupling to drive the vacuum device.

[0018] The inlet of the centrifugal pump 10 is connected to the suction pipeline 1, the outlet is provided with an outlet connecting pipe fitting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com