Construction Method of Saddle-shaped Access Road in Expressway

A technology for the construction of access roads and highways, applied in road repair, roads, roads, etc., can solve the problems of increasing the difficulty, occupation, and inability of rolling by road rollers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

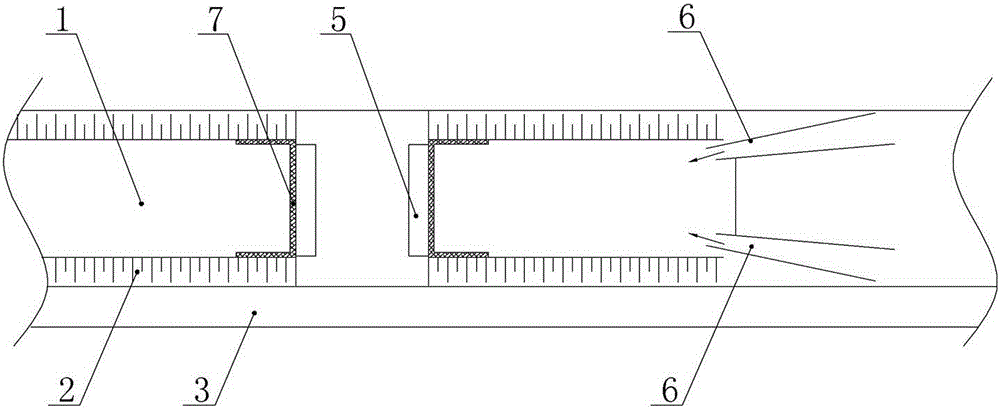

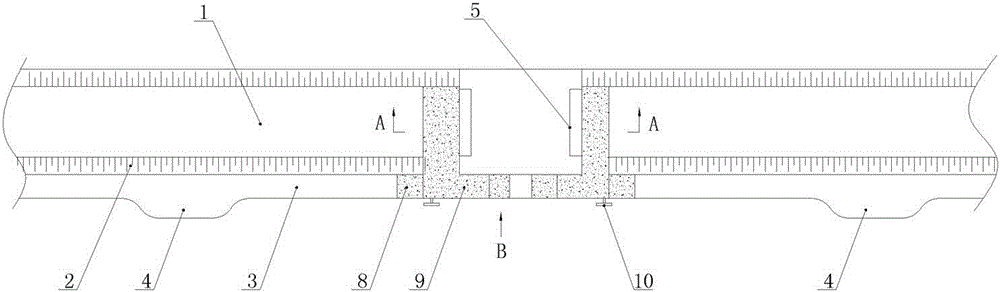

[0029] Example 1: A method for constructing a saddle-shaped construction access road for expressway. On one or both sides of the highway roadbed to be built, a construction access road with the same direction as the highway roadbed is built; for bridges, At culverts and passage structures, their corresponding construction access roads adopt the principle of bionics, and the construction access roads are constructed in a saddle shape. The construction methods of the construction access roads mainly include the following steps:

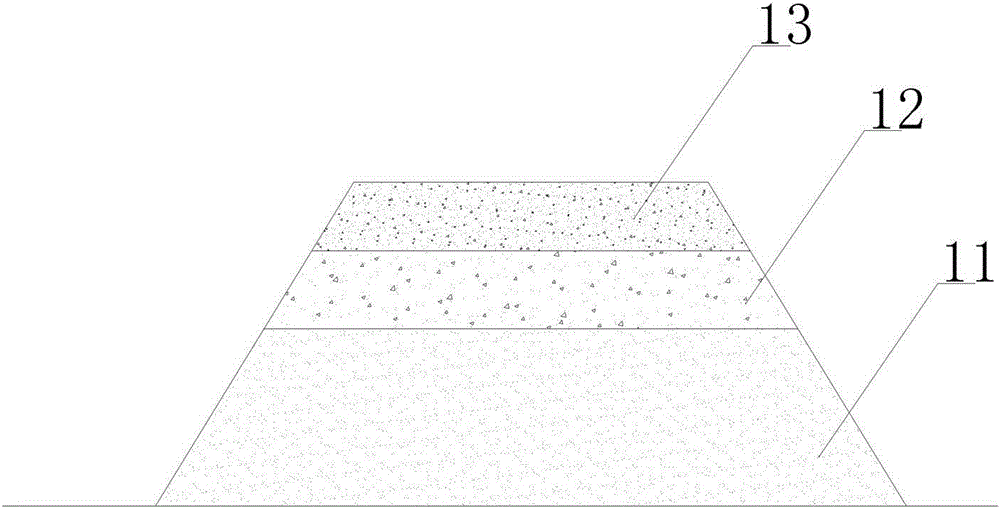

[0030] 1) Clean the surface of the original ground, level and roll it several times, and then pave it with simple surface materials such as brick slag, stone chips, etc., level and roll it to form a construction road;

[0031] 2) Within the range of 5~10m from the design of bridges, culverts, and passage structures corresponding to the highway for the construction access road, as the height of the highway subgrade soil filling continues to increase, the corre...

Embodiment 2

[0035] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the saddle-shaped construction access road is a series of universal rods, berets, and general Steel components assembled by general rods or special rods. According to different highway subgrade heights, the saddle-shaped construction access road needs to be compensated for the height of the steel components of the subgrade part and the subgrade slope, spliced and heightened and embedded in the subgrade appropriately For the side slope part, the length and height of the slope steel members at both ends are extended and heightened according to the requirements of the longitudinal slope.

[0036] The top surface of the steel member is a movable pavement device connected by riding bolts. The movable pavement device is a movable steel temporary bridge deck structure that has been manufactured in advance according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com