Loom for weaving zigzag warp and weft woven fabric

A technology of warp and weft machines and looms, which is applied to fabrics, looms, textiles, and papermaking. It can solve the problems of high energy consumption, complex reed layout and manufacturing, and high cost, and achieve low requirements for process adjustment and novel and unique appearance. , The effect of small transformation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

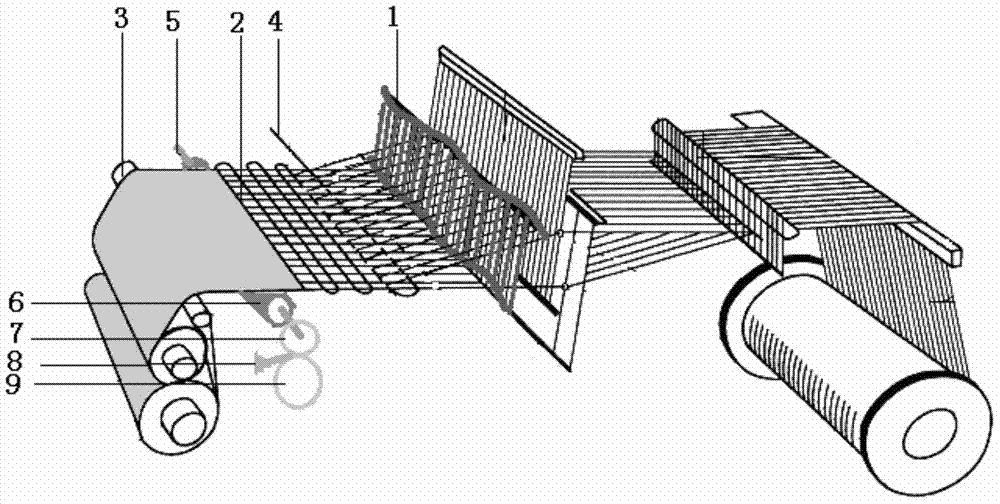

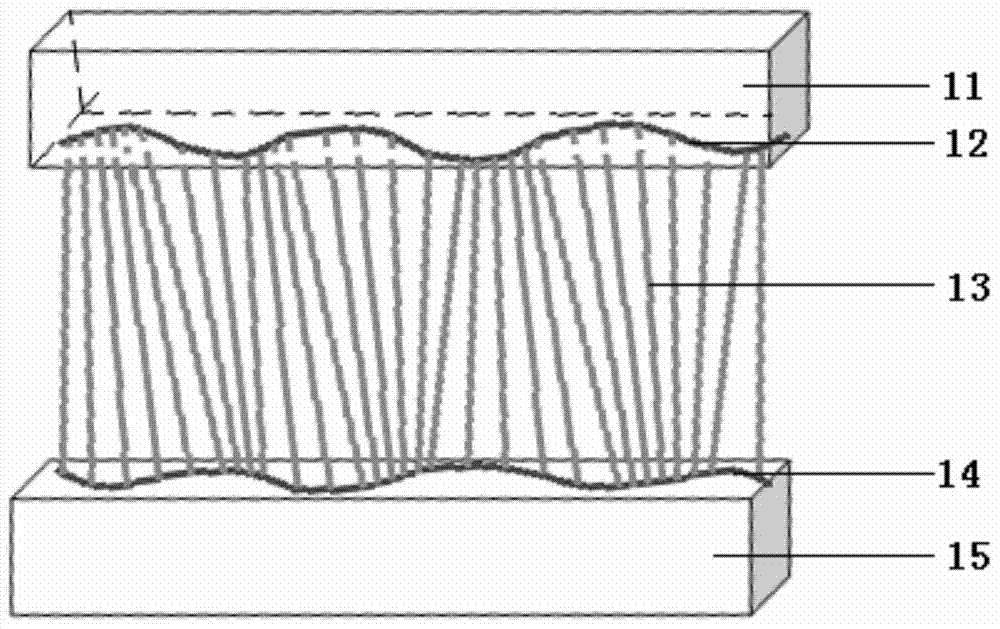

[0049] combine image 3 , Figure 4 As shown, the loom for weaving zigzag warp and weft woven fabrics provided in this embodiment can weave woven fabrics in which warp yarns are arranged in parallel straight lines and weft yarns are arranged in parallel in zigzag lines.

[0050] The loom special reed 1 and eccentric roller are configured as follows:

[0051] 1, the preparation of loom special steel reed 1:

[0052] (1) Make 2 equal-length reed beams and 2 equal-height end beams from steel materials with the same shape as common steel reeds and a width of 15mm; vertically weld the reed beams and end beams respectively to form a rectangular reed frame , the interval between upper and lower reed beams is 120mm;

[0053] (2) Use 2 steel wires with a diameter of 0.6mm to wind a positioning spring 16 with a diameter of 1.5mm; bend the 2 positioning springs 16 into an irregular broken line shape, and the maximum bending range of the broken line is 13mm. The polylines have the sam...

Embodiment 2

[0060] combine Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, the invention provides a weaving machine for weaving zigzag warp and weft woven fabrics, which can weave woven fabrics in which the warp yarns are arranged in straight lines and the weft yarns are arranged in zigzag lines.

[0061] The specific processing method is as follows:

[0062] 1, the preparation of loom special steel reed 1:

[0063] (1) Choose the same shape as common steel reed, aluminum alloy material with a width of 15mm to make 2 reed beams of equal length and 2 end beams of equal height; vertically weld the reed beams and end beams respectively to make a rectangular reed frame , the distance between the upper and lower reed beams is 150mm;

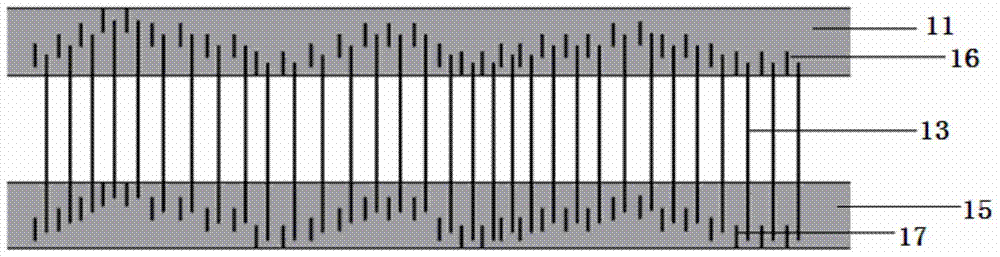

[0064] (2) select the steel wire that diameter is 0.5mm for use, be wound into the positioning spring 16 that diameter is 1.6mm; The shape of the curves on the reed beams is not the same (see Figure 5 ), and the spring is bonded on the reed beam; ...

Embodiment 3

[0080] combine Figure 9 , Figure 10 , Figure 11 , Figure 12 As shown, the present invention provides a weaving machine for weaving zigzag warp and weft woven fabrics, which can weave woven fabrics in which warp yarns are arranged in varying zigzag lines and weft yarns are arranged in parallel zigzag lines.

[0081] The configuration of special reed and eccentric roller for the loom is as follows:

[0082] 1, the preparation of loom special steel reed 1:

[0083] (1) Choose the same shape as ordinary steel reed, aluminum alloy material with a width of 18mm to make 2 equal-length reed beams and 2 equal-height end beams; vertically weld the reed beams and end beams respectively to form a rectangular reed frame , the distance between the upper and lower reed beams is 130mm;

[0084] (2) select the nylon wire that diameter is 0.4mm for use, be wound into the positioning spring 16 that diameter is 1.4mm; Figure 9 ), the maximum curve bending range is 16mm, the shape of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com