Twisting device of direct twisting machine

A technology of twisting device and direct twisting machine, which is applied in the direction of textiles and papermaking, etc. It can solve the problems of shortening the service life of the electric spindle motor, the easy bending of the electric spindle shaft, and motor damage, etc., and achieves the increase of wear-resistant material top cover and the reduction of breakage. Yarn phenomenon, the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

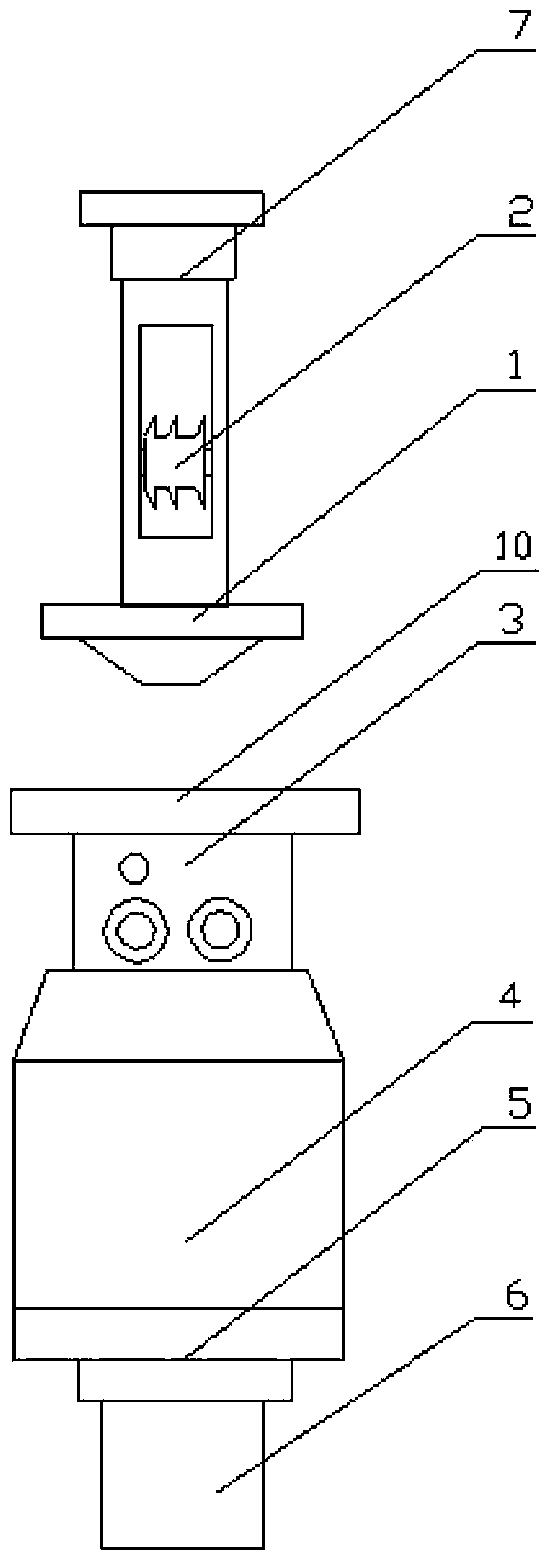

[0013] See figure 1 , the present invention has a twist leveler 1, a guide wheel 2, an inner yarn tensioner 3, a spindle pot 4, a spindle 5, and an electric spindle motor 6; the middle part of the twist leveler 1 is a hollow structure, and the upper part has a lightweight shock-absorbing connection device 7 for A circular nylon shock-absorbing connection block, the twist leveler 1 is fixedly connected to the wallboard above the twisting device of the straight twisting machine through the shock-absorbing connection device 7.

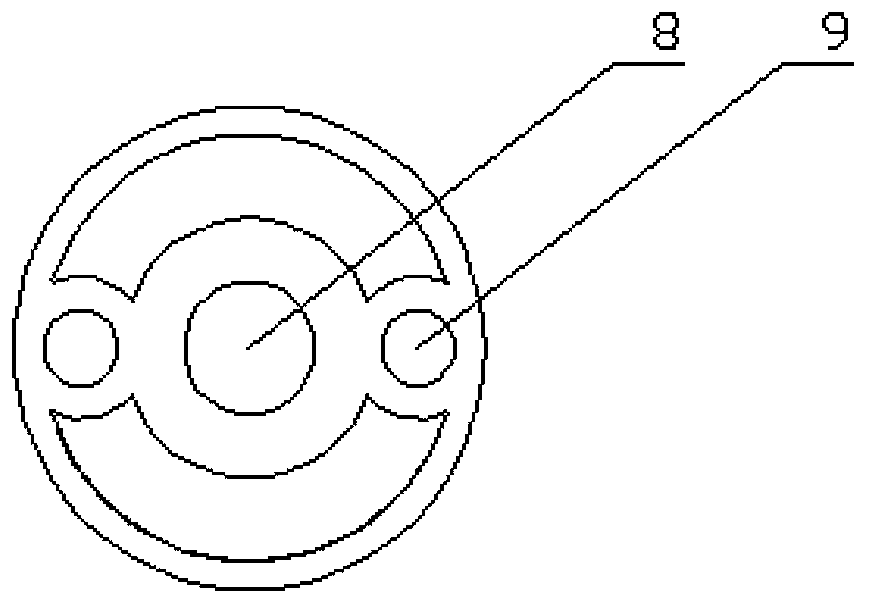

[0014] The middle part of the nylon damping connection block has a through hole 8, and the two ends of the through hole 8 are screw holes 9. The bolts are fixed on the wallboard of the straight twisting machine through the screw holes 9, and there are symmetrical weight-reducing grooves on the nylon damping block.

[0015] The guide wheel 2 is fixed at the position below the hollow structure of the twist leveler 1 through the mandrel; it is a double ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com