Preparation method of loaded Y-type molecular sieve membrane anode material for photoelectrocatalytic oxidation

A photoelectric catalysis, molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low visible light photocatalytic efficiency, long preparation process, low adsorption efficiency, etc., to improve photoelectric catalysis The effect of performance, convenient operation and fast degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0040] Example 1: Dissolve 2mL of tetra-n-butyl titanate in 30mL of absolute ethanol to form mixed solution A, and stir. Add 10 mL of concentrated nitric acid dropwise to mixed solution A to form mixed solution B, and stir.

[0041] The mixed solution B was slowly added dropwise into 50 mL of deionized water, stirred evenly and left to stand for a period of time to form Sol C.

[0042] Sol C is slowly added dropwise onto the prepared supported Y-type molecular sieve membrane under the condition of stirring until the whole molecular sieve membrane support is submerged. After standing for 48 hours, rinse with deionized water and dry. Put it into 40mL of n-butylamine, let it stand for 12h, rinse it with deionized water, and dry it. Finally, put it into a muffle furnace and bake at 800° C. for 2 hours to prepare a Y-type molecular sieve membrane-loaded nitrogen-doped titanium dioxide.

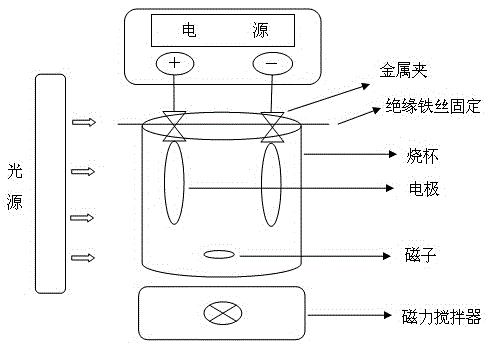

[0043] Application: such as figure 1 Assembled photoelectric catalytic oxidation device sho...

example 2

[0044] Example 2: Dissolve 5 mL of tetra-n-butyl titanate in 10 mL of absolute ethanol to form mixed solution A, and stir. Add 6 mL of concentrated nitric acid dropwise to mixed solution A to form mixed solution B, and stir.

[0045] The mixed solution B was slowly added dropwise to 40mL deionized water, stirred evenly and left to stand for a period of time to form Sol C.

[0046] Sol C is slowly added dropwise onto the prepared supported Y-type molecular sieve membrane under the condition of stirring until the whole molecular sieve membrane support is submerged. After standing for 12 hours, rinse with deionized water and dry. Then put it into 30mL of n-butylamine, let it stand for 48h, rinse it with deionized water, and dry it. Finally, put it into a muffle furnace and bake at 300° C. for 10 hours to prepare a Y-type molecular sieve membrane-loaded nitrogen-doped titanium dioxide.

[0047] Application: This material is used as an anode material for photoelectric catalytic ...

example 3

[0048] Example 3: Dissolve 10 mL of tetra-n-butyl titanate in 20 mL of absolute ethanol to form mixed solution A, and stir. Add 2 mL of concentrated nitric acid dropwise to mixed solution A to form mixed solution B, and stir.

[0049] Slowly add B to 60mL deionized water dropwise, stir evenly and let it stand for a while to form Sol C.

[0050] Sol C is slowly added dropwise onto the prepared supported Y-type molecular sieve membrane under the condition of stirring until the whole molecular sieve membrane support is submerged. After standing for 36 hours, rinse with deionized water and dry. Then put it into 40mL of n-butylamine, let it stand for 36h, rinse it with deionized water, and dry it. Finally, put it into a muffle furnace and bake at 500° C. for 5 hours to prepare a Y-type molecular sieve membrane-loaded nitrogen-doped titanium dioxide.

[0051] Application: This material is used as an anode material to treat phenol wastewater by photoelectric catalytic oxidation. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com