Hybrid power system

A hybrid power system and gearbox technology, which is applied to power units, pneumatic power units, electric components, etc., can solve the problems of waste, restriction, and increase in axial length of the transmission system, and achieve convenient installation, cost saving, and convenient modification. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to elaborate on the technical solutions adopted by the present invention to achieve the predetermined technical objectives, the following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described implementation The examples are only part of the embodiments of the present invention, not all of the embodiments, and, without creative work, the technical means or technical features in the embodiments of the present invention can be replaced. The following will refer to the accompanying drawings in combination The examples illustrate the present invention in detail.

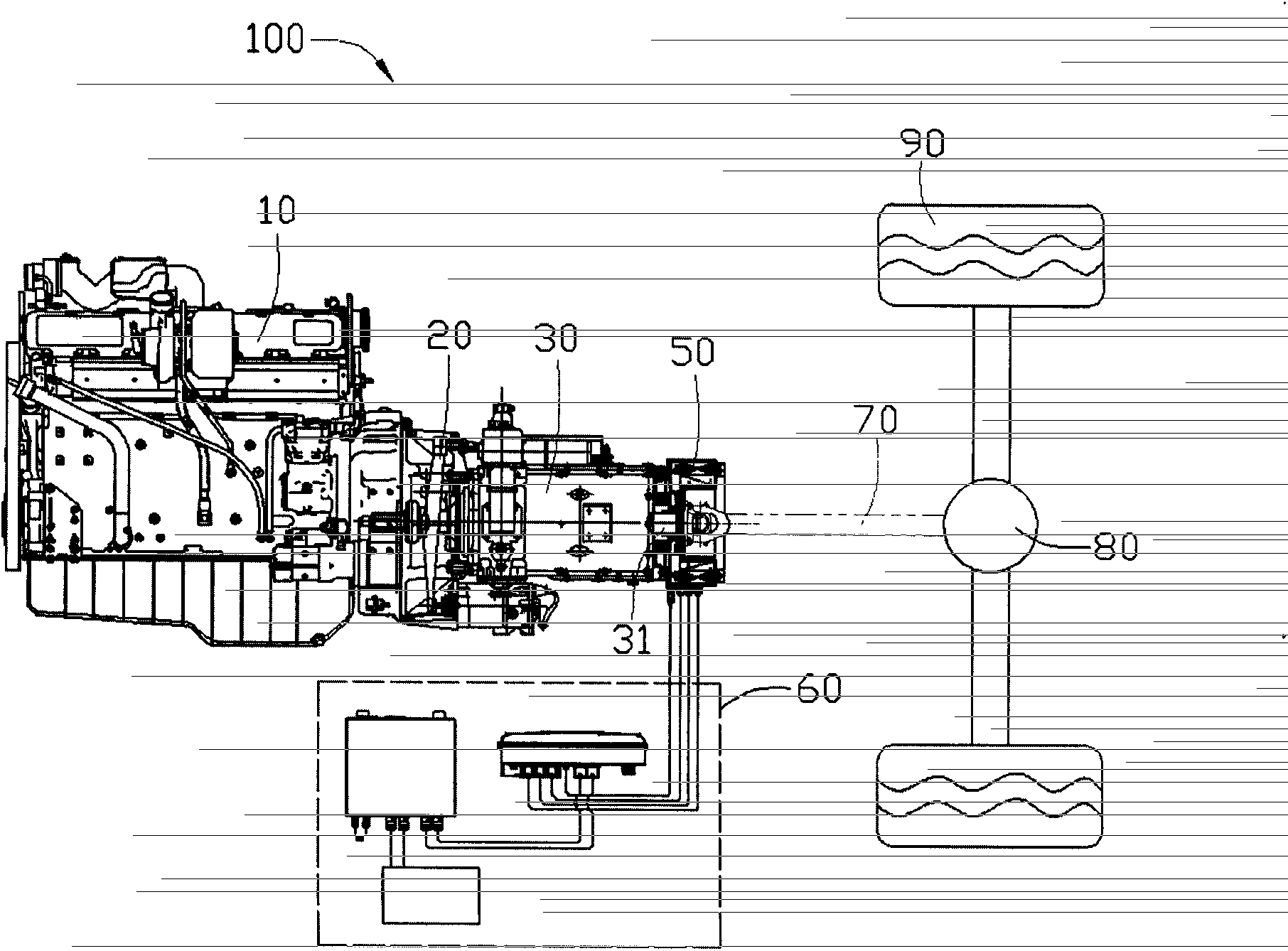

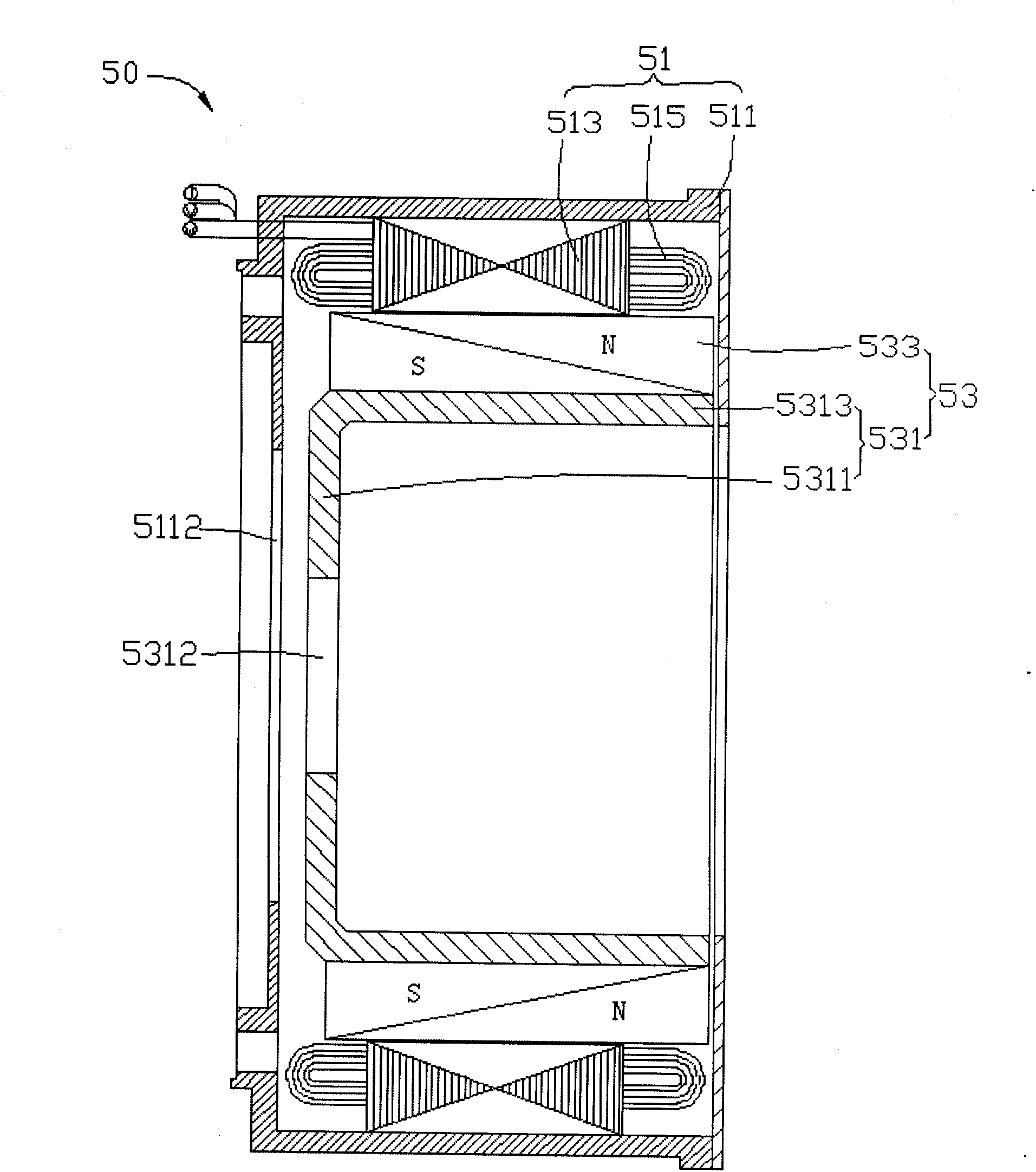

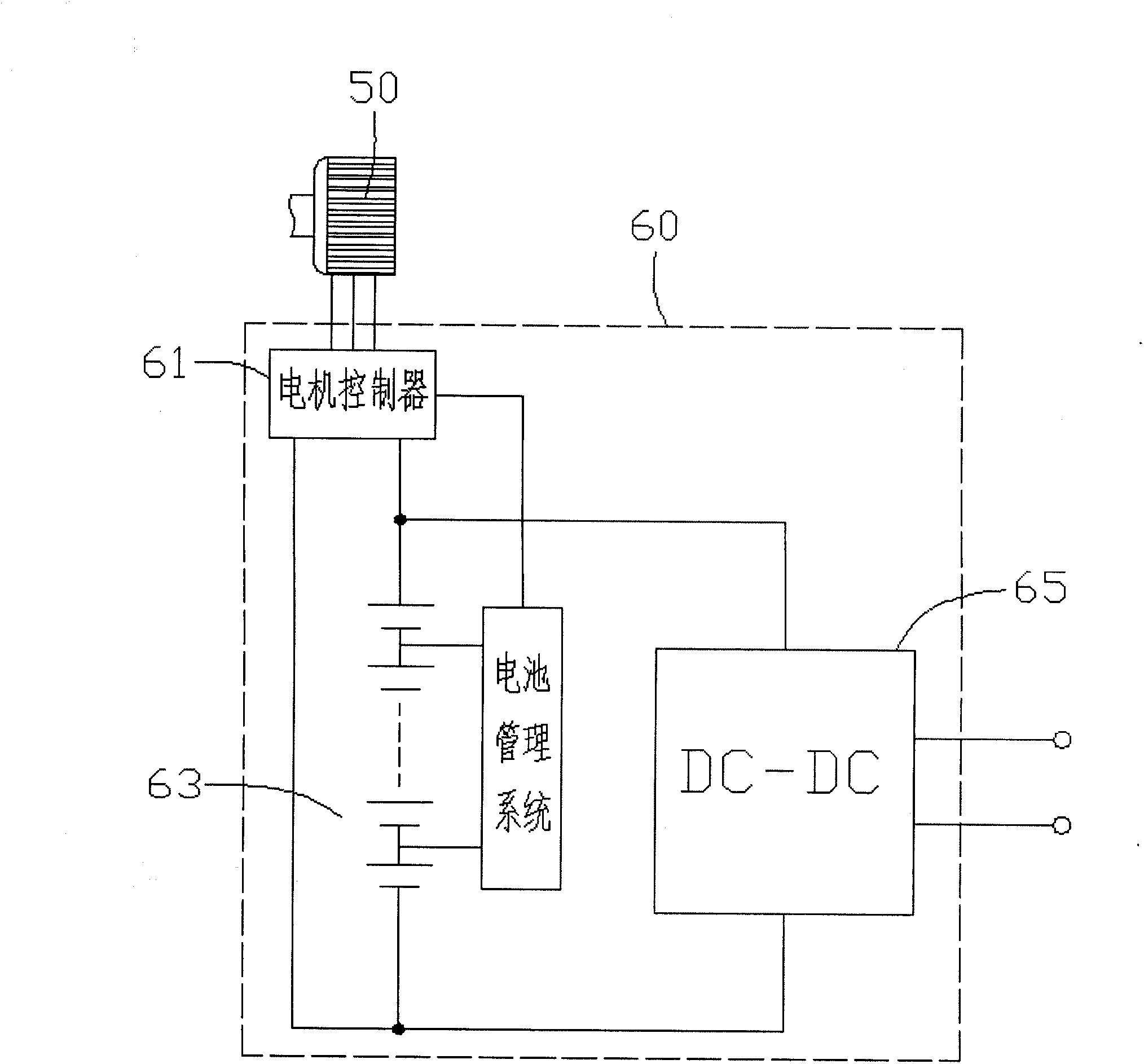

[0021] See figure 1 The present invention provides a hybrid power system 100, which includes an engine 10, a clutch 20, a gearbox 30, a hollow bearingless motor 50, an electronic control unit 60, a universal joint shaft 70, a differential 80 and wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com