Vibration-state on-line monitoring method of high-speed wire rod finishing block

A high-speed wire rod and finishing mill technology, applied in length measuring devices, metal rolling, metal rolling, etc., can solve problems such as shaft sleeve or spacer loosening, shaft wear, and relative rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

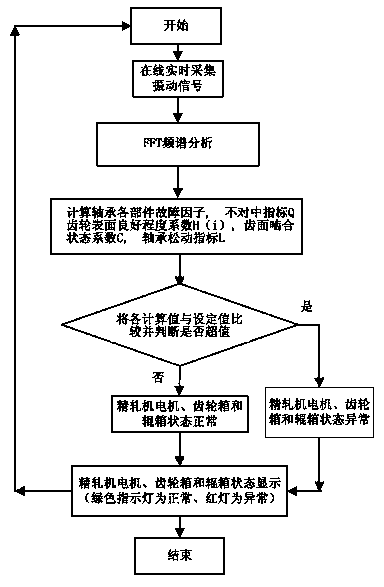

[0036] Such as figure 1 As shown, the method for on-line monitoring of the vibration state of the high-speed wire finishing mill of the present invention comprises the following steps:

[0037] Step 1. Install vibration sensors for outputting vibration signals on each bearing block of the motor, gear box and roll box of the finishing mill, collect the original output signal Yi of each vibration sensor, and calculate the original output signal Y i Perform frequency spectrum analysis to extract the characteristic signal of the finishing mill;

[0038] Step 2. The relative speed frequency f of the inner and outer rings of each housing bearing is calculated from the original output signal of step 1. r , the bearing failure of each bearing seat is manifested in the abnormal vibration level value with impact, and the relationship between the vibration characteristic frequency of each component of the bearing and the bearing parameters is

[0039] Vibration spectrum of bearing oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com