Gas density monitoring device for realizing maintenance-free of density relay, system and method

A technology of density relay and gas density, which is applied in the field of electric power, and can solve problems such as the reduction of insulation strength on the surface of insulating parts, flashover, and hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

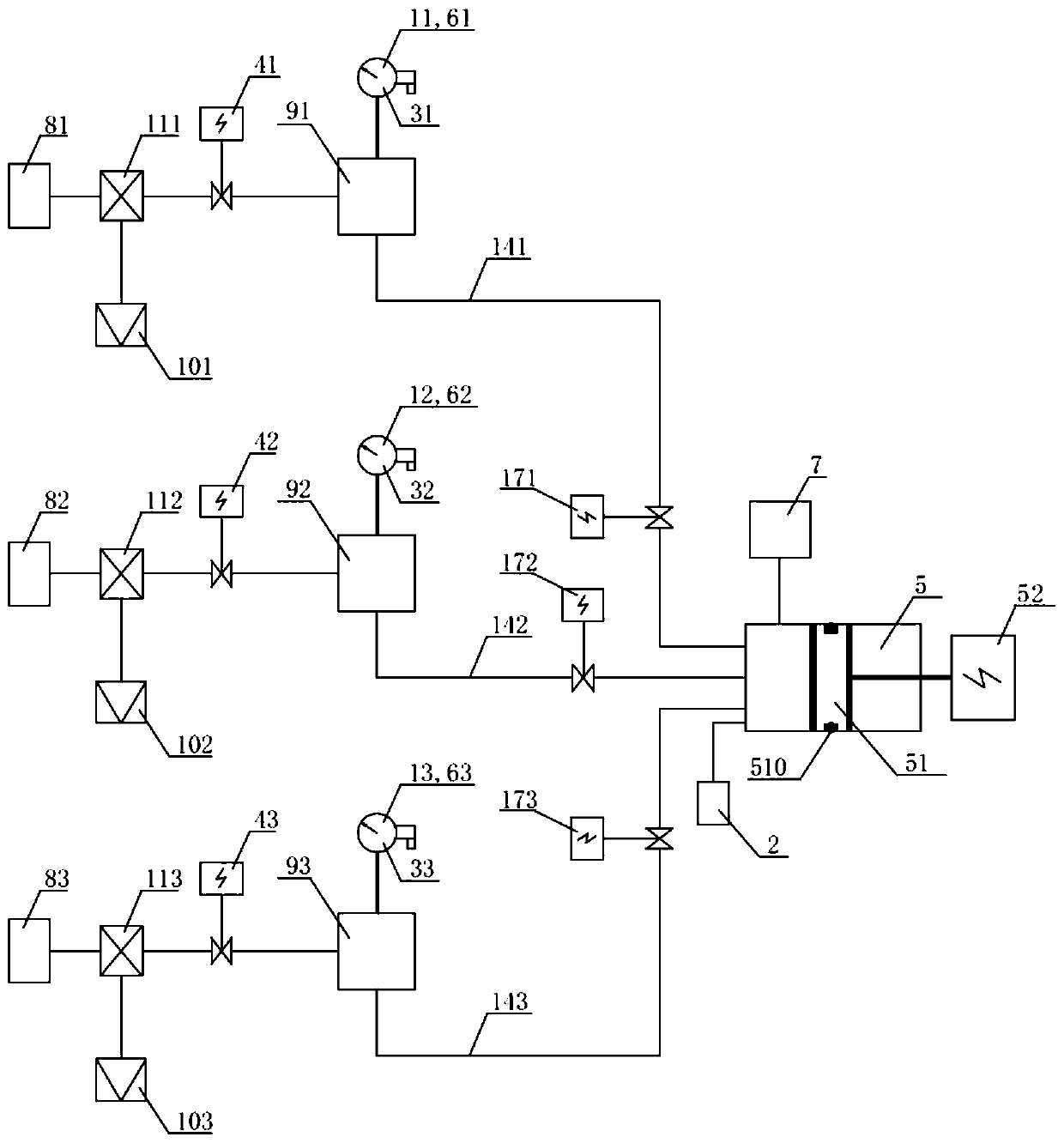

[0147] Such as figure 1 As shown, a gas density monitoring device that realizes maintenance-free density relays includes: a pressure regulating mechanism 5, an intelligent control unit 7, and a pressure sensor 2, and the pressure sensor 2 is connected to the pressure regulating mechanism 5 on an air circuit. The gas path of the pressure regulating mechanism 5 is divided into three branches through connecting pipes, namely a first branch 141 , a second branch 142 and a third branch 143 . Each branch is equipped with a pre-valve, a multi-way joint, a post-valve, a temperature sensor and an on-line verification contact signal sampling unit. Among them, one end of each pre-valve is provided with an interface connected with its corresponding electrical equipment, and the other end of the pre-valve is connected with the gas path of the corresponding gas density relay through a multi-way joint; one end of each post-valve The gas path of the corresponding gas density relay is connect...

Embodiment 2

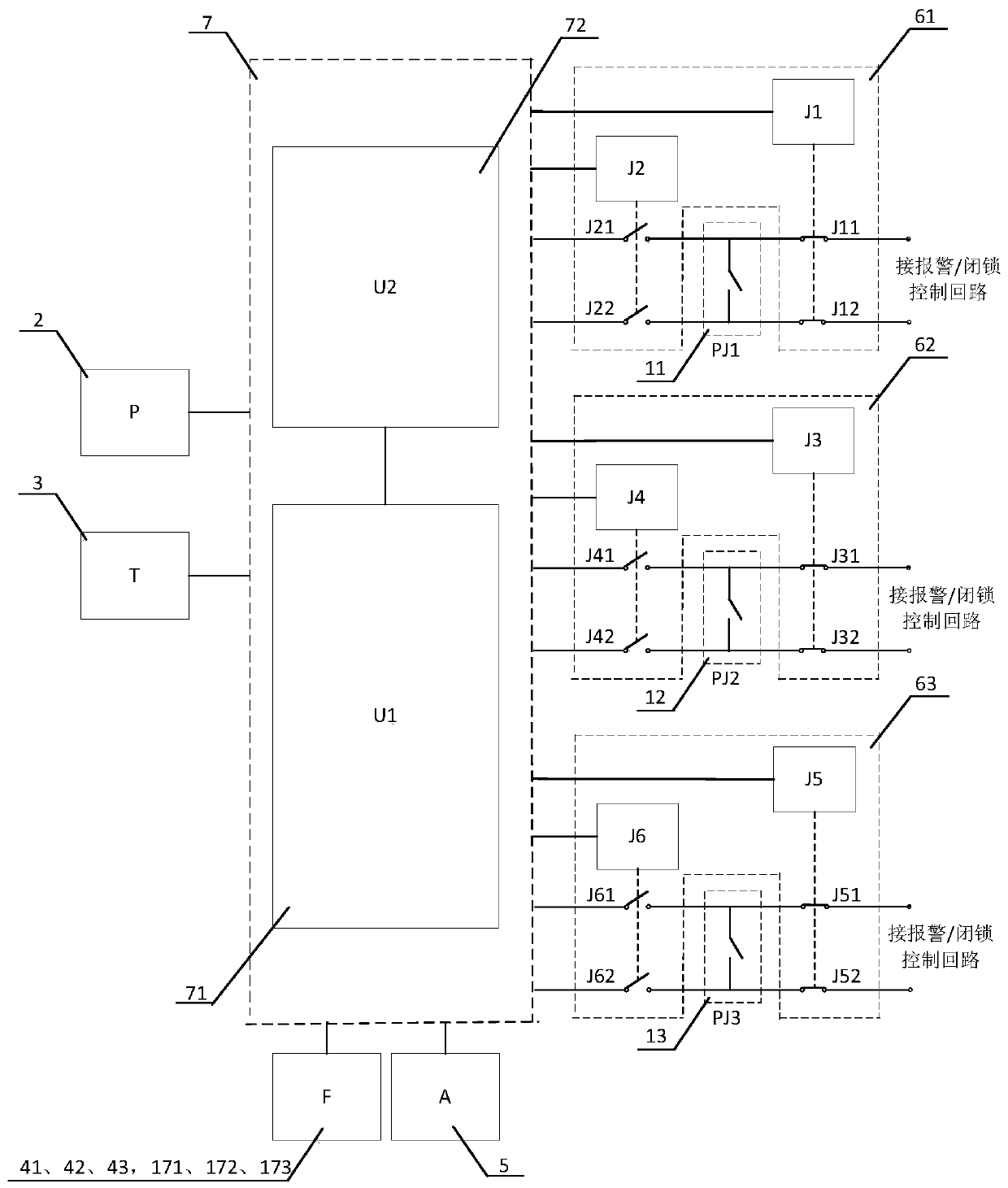

[0158] figure 2 It is a schematic diagram of the control circuit of a gas density monitoring device. Such as figure 2 As shown, the gas path of the pressure regulating mechanism 5 is connected with three branches, and each branch is provided with an online verification contact signal sampling unit, which has the same structure, and is respectively an online verification contact signal sampling unit 61, an online verification Contact signal sampling unit 62 and online verification contact signal sampling unit 63, the online verification contact signal sampling unit on each branch is provided with a sampling contact connected to the gas density relay on the branch, configured to sample the gas The contact signal of the density relay and the online verification contact signal sampling unit on each branch are also connected with the intelligent control unit 7 .

[0159] The basic requirements or functions of the online verification contact signal sampling unit on each branch a...

Embodiment 3

[0178] Such as image 3 As shown, the difference between the gas density monitoring device of this embodiment and Embodiment 1 is:

[0179] The pressure regulating mechanism 5 of this embodiment is mainly composed of an air bag 53 and a driving part 52 . According to the control of the intelligent control unit 7 , the pressure regulating mechanism 5 makes the driving part 52 push the air bag 53 to change in volume, and then complete the pressure rise and fall. The pressure is regulated by the pressure regulating mechanism 5, so that the gas density relay on the branch takes a contact action, and the contact action is transmitted to the intelligent control unit 7 through the online verification contact signal sampling unit on the corresponding branch. The pressure value and temperature value when the contact action of the gas density relay is converted into the corresponding density value, and the contact action value and / or return value of the gas density relay on the corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com