The temperature control method of the diamond six-sided top press

A six-sided top press, diamond technology, applied to the method of using atmospheric pressure to chemically change substances, chemical instruments and methods, and the process of applying ultra-high pressure, etc., can solve temperature curve tracking errors, stagnation, no Considering other issues to achieve the effect of short control time, simple method and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The temperature control method of the diamond six-sided top press contains the following steps:

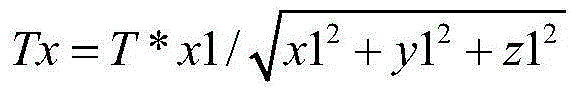

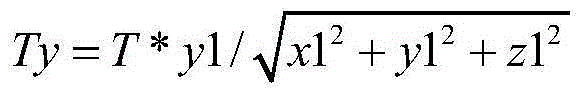

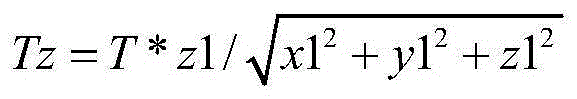

[0024] Step 1: When no external heat source is applied, the pressure and temperature of the center point of the inner cavity of the diamond six-sided press are the highest, and the three-axis three-dimensional coordinates are established with the center point of the inner cavity of the diamond six-sided press as the coordinate origin system, the three coordinate axes of the three-axis three-dimensional coordinate system are x-axis, y-axis, and z-axis respectively; s heat sources are set in the inner cavity of the diamond six-sided top press, s is a natural number greater than or equal to 1, s Each heat source is used to heat the inside of the cavity; each heat source has a coordinate P in the three-axis three-dimensional coordinate system, and the coordinate P is expressed as: (x1, y1, z1), and the heat emitted by each heat source may be different. The temperature value of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com