Quadrigeminal compound preparation of anti-tuberculosis medicines and preparation method thereof

A compound preparation and anti-tuberculosis technology, applied in the field of medicine, can solve the problems of irregular drug use, difficulty in completing regular chemotherapy, and lack of systems and measures for strict management of tuberculosis patients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

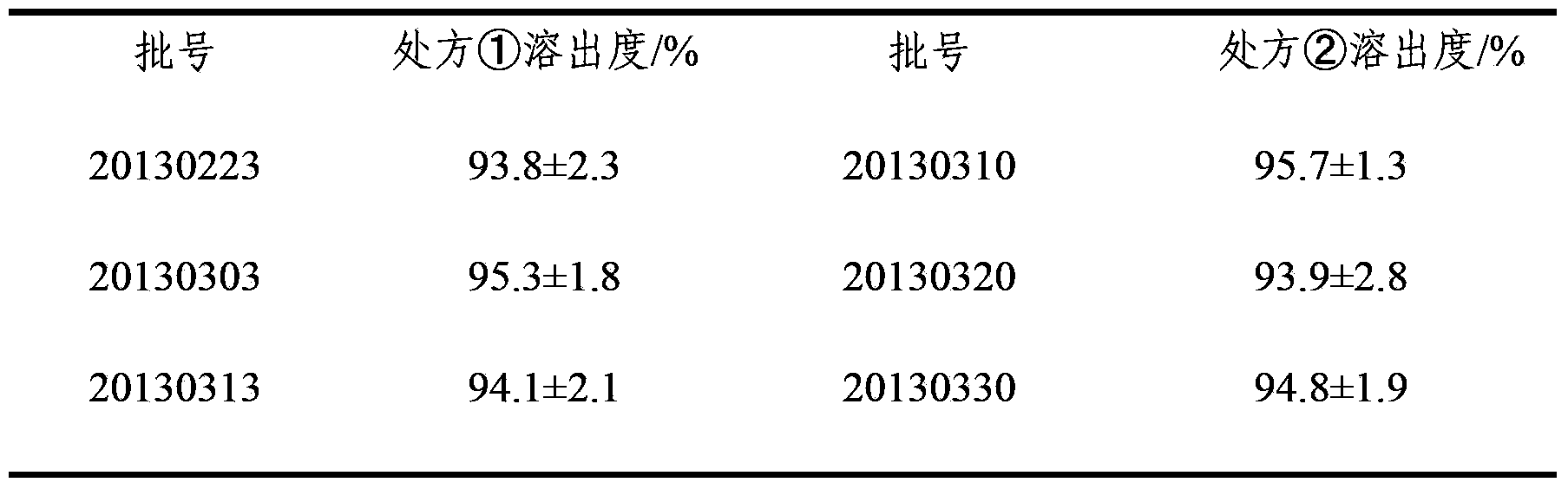

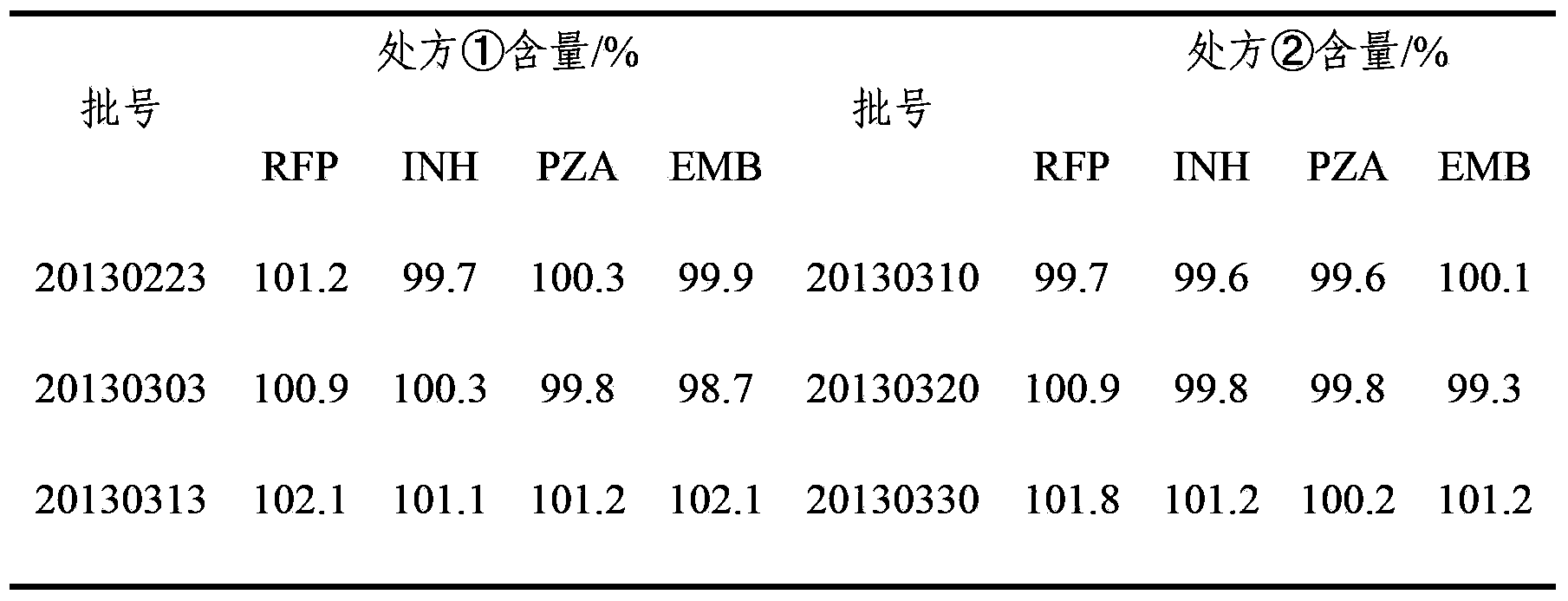

Examples

Embodiment 1

[0029]

[0030] Coating prescription

[0032] Water: Appropriate amount

[0033] Preparation:

[0034] (1) Sieve

[0035] Rifampicin is passed through a 80-mesh sieve, and other raw materials are passed through a 20-mesh sieve for subsequent use;

[0036] (2) Mixed granulation

[0037] Weigh isoniazid, ethambutol hydrochloride, pyrazinamide, PVPP (additional part), MCC, PVPK30 according to the prescription amount, mix in a high-speed wet mixer for 10 minutes (stirring speed 500-800r·min - 1 ), adding an appropriate amount of water to make soft materials, 40-mesh sieve to make granules, drying at 60±5°C, and controlling the moisture content below 1.5%;

[0038] (3) whole grain

[0039] Use a 65-mesh stainless steel sieve for granulation;

[0040] (4) mixed

[0041] Put the granulated material in a three-dimensional mixer, add the prescribed amount of rifampicin, sodium lauryl sulfate, PVPP, SIO2, MS and mix for 15 minutes;

[0042] (5) ...

Embodiment 2

[0049]

[0050] Coating prescription

[0051] Coating powder: 40g

[0052]Water: Appropriate amount

[0053] Preparation:

[0054] (1) Sieve

[0055] Rifampicin is passed through a 80-mesh sieve, and other raw materials are passed through a 20-mesh sieve for subsequent use;

[0056] (2) Mixed granulation

[0057] Weigh isoniazid, ethambutol hydrochloride, pyrazinamide, PVPP (additional part), MCC, PVPK30 according to the prescription amount, mix in a high-speed wet mixer for 10 minutes (stirring speed 500-800r·min - 1 ), adding an appropriate amount of water to make soft materials, 40-mesh sieve to make granules, drying at 60±5°C, and controlling the moisture content below 1.5%;

[0058] (3) whole grain

[0059] Use a 65-mesh stainless steel sieve for granulation;

[0060] (4) mixed

[0061] Put the granulated material in a three-dimensional mixer, add the prescribed amount of rifampicin, sodium lauryl sulfate, PVPP, SIO2, MS and mix for 15 minutes;

[0062] (5) I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com