How to ensure the accuracy of oee stop timing

A technology of timing accuracy and downtime, which is applied in hardware monitoring and other directions, can solve the problems of the accuracy of statistical results, downtime calculation, downtime classification and statistics, etc., and achieve the effect of reducing manual recording errors and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

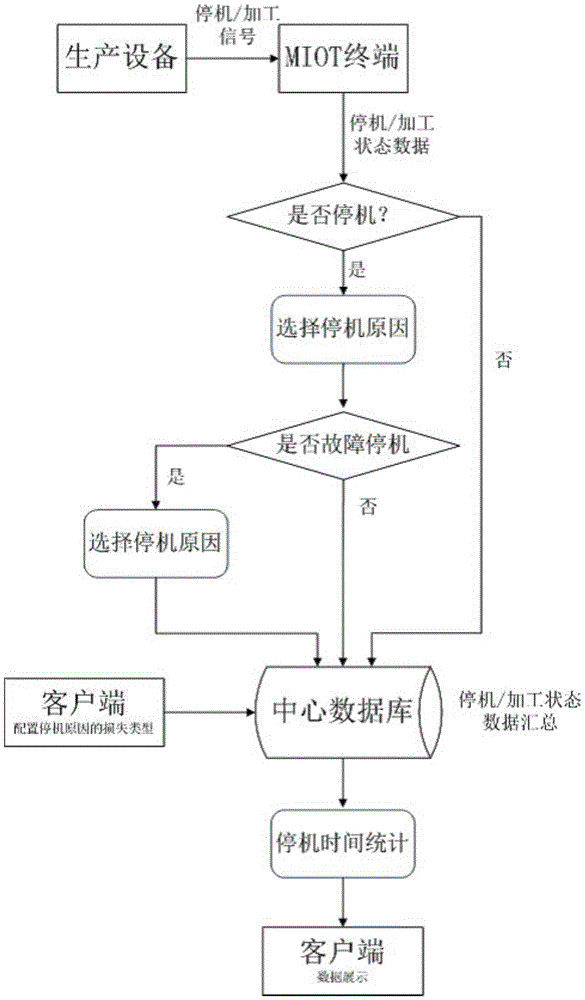

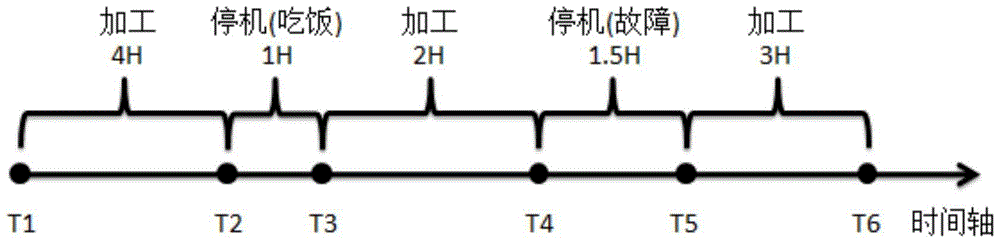

[0027] Example 1: Such as figure 1 As shown, methods to ensure the accuracy of OEE shutdown timing include:

[0028] 1) The production equipment is connected with the MIOT terminal, and the MIOT terminal collects the working signal and signal duration of the production equipment in real time, and uploads it to the central database for storage;

[0029] 2) The client configures the cause of the downtime. The cause of the downtime includes planned and unplanned downtime. The client uploads the configuration information to the central database for storage; the central database sends the configuration information to the MIOT terminal;

[0030] 3) Shutdown judgment:

[0031] 3.1) The MIOT terminal judges whether the working signal becomes a stop signal:

[0032] If so, the MIOT terminal records the downtime point, the operator selects the reason for the downtime at the MIOT terminal, the MIOT terminal uploads the downtime reason and downtime point to the central database for storage, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com