Full-automatic volume measurement device and production method thereof

A technology of volume measurement and production method, which is applied in the direction of volume measurement instrument/method, measurement device, liquid/fluid solid measurement, etc., which can solve the problems of difficult automatic operation, high labor intensity, and low accuracy, and achieve high biochemical safety , high degree of automation, good operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following specific embodiments are used to illustrate the technical solutions of the present invention, but the protection scope of the present invention is not limited thereto.

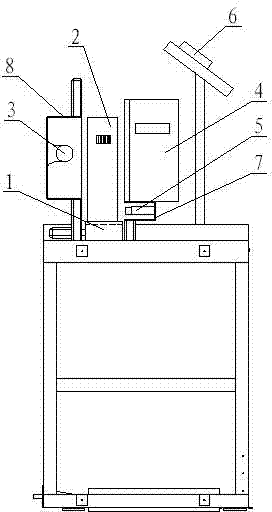

[0015] Such as figure 1 As shown, a fully automatic volume measuring device includes a conveying rail 1, a sample box 2, an infrared sensor 5, a CCD sensor 4, and a controller 6. The sample box 2 contains a diluent of human or animal excrement to be detected .

[0016] The conveying guide 1 can adopt any of chain conveying, belt conveying or screw nut conveying. A row of sample boxes 2 arranged in sequence is placed on the conveying guide 1, and the sample boxes 2 are of known cross-sectional area. Transparent regular containers, such as transparent cylindrical sample box 2, transparent oval sample box 2, transparent rectangular sample box 2, etc., which contain a mixture of diluent and excretion.

[0017] An infrared sensor 5 for sensing the position of the sample box 2 and a CCD sensor 4 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com