Clutch assisting device

A technology of booster and clutch, applied in clutch, filter separation, separation method, etc., can solve the problems of clutch booster failure, easy to pull cylinder block and seals, etc., and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

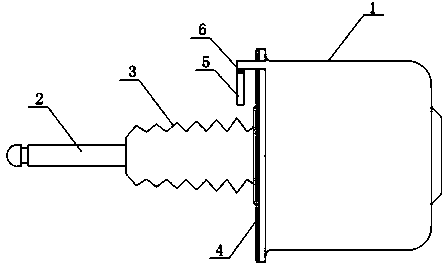

[0010] Such as figure 1 As shown, the present invention provides a clutch booster, comprising a cylinder 1, a push rod 2 and a dust cover 3, the dust cover 3 adopts a corrugated connection circular tube, and one end of the dust cover 3 is sealed and fixedly connected with the push rod 2, The other end of the dust cover 3 is sealed and fixedly connected with the front cover plate 4 of the cylinder. Since the force here is small, the sealant connection can be used to ensure that the dust cover 3 is a fully sealed structure. The upper part of the front cover plate 4 of the cylinder is provided with a ventilation pipe 5. The ventilation pipe 5 is in an inverted L shape. One end of the ventilation pipe 5 communicates with the cylinder 1, and the other end of the ventilation pipe 5 communicates with the outside world and faces downward. An air filter device is arranged in the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com