Novel assembled type beam column joint connecting structure

A technology of beam-column joints and connection structures, which is applied in the direction of building construction and construction, can solve the problems of complex construction procedures, large welding area, poor joint ductility, etc., and achieve low industrialization level, high industrialization level, and fast construction speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

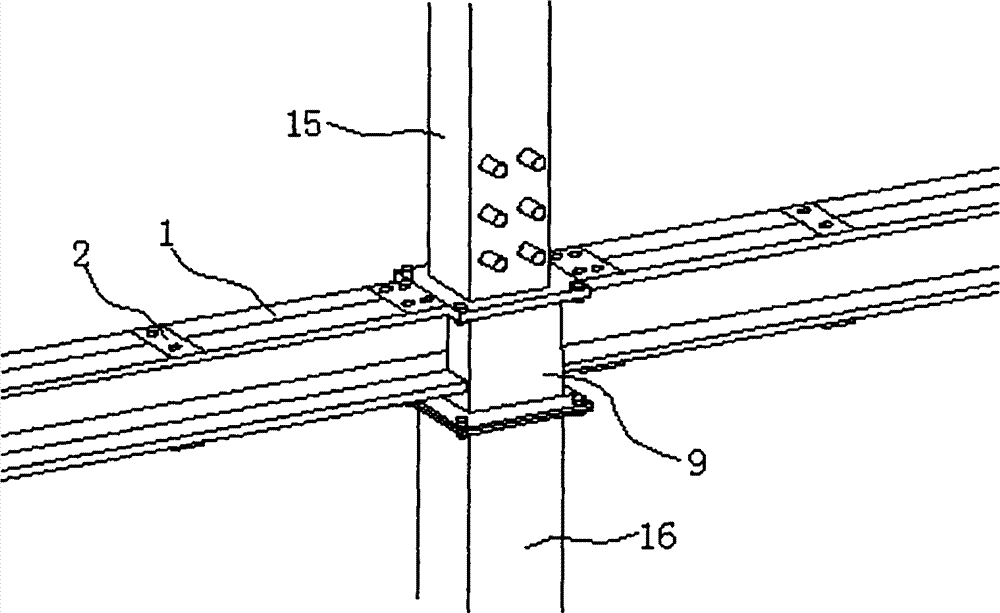

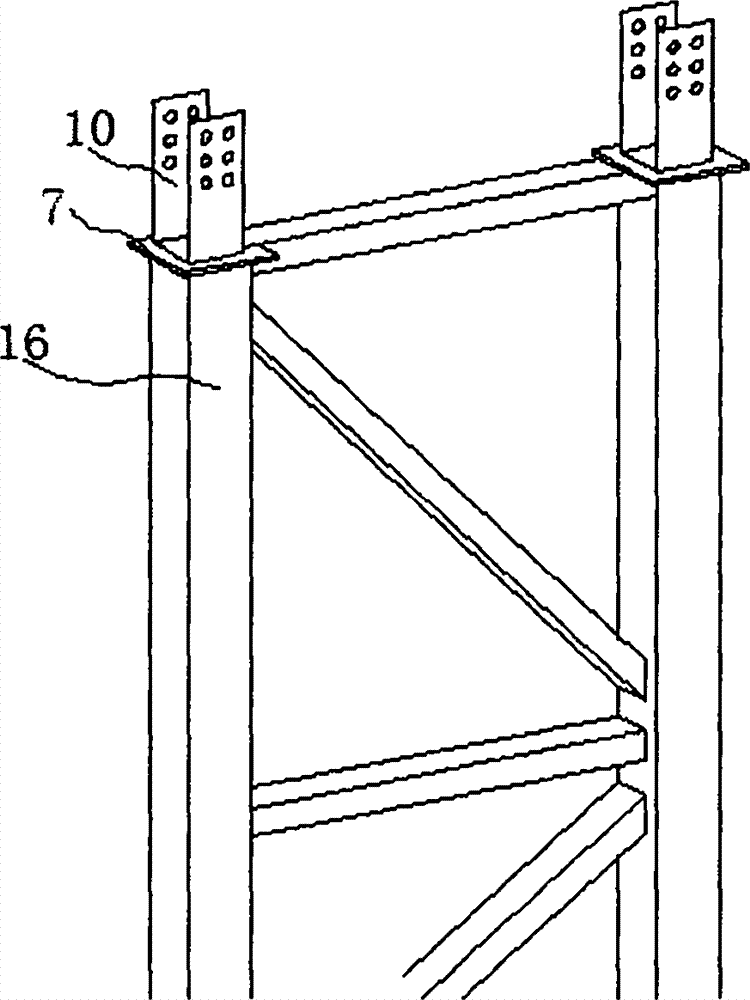

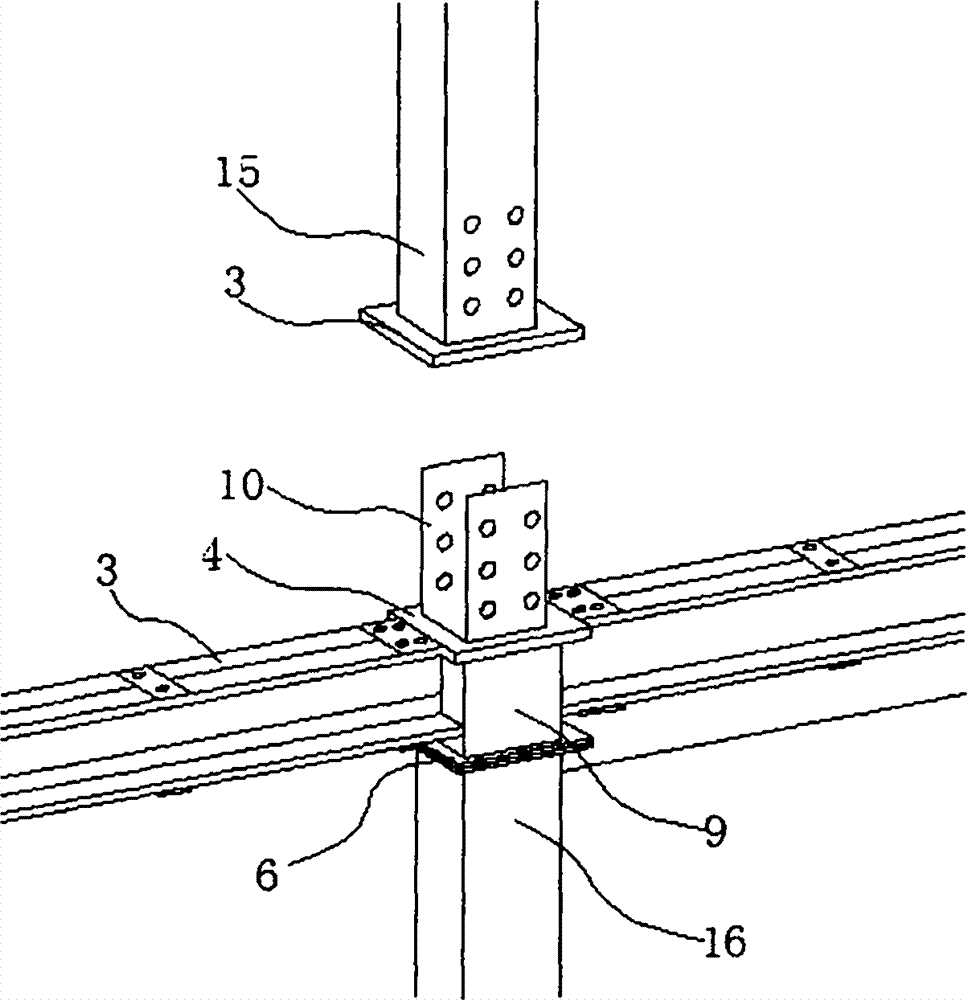

[0016] see Figure 1-3 , it includes a chord frame, and the chord frame includes a beam, a sleeve 9 arranged between the beams and a lower column 16 respectively plugged with the sleeve 9 and the upper column 15; the beam consists of two Composed of parallel angle steel beams 1, two adjacent angle steel beams 1 are welded into a whole through angle steel beam connecting plates 2, and the sleeve 9 as a whole is a cuboid structure with openings at both ends. The sleeve upper flange 4 and the sleeve lower flange 6 are respectively welded, and the upper part of the lower column 16 is welded with two lower column end plates 10 which are plugged with the sleeve 9, and the other end plate 10 of the lower column One end extends through the sleeve 9 into the upper column 15, and is screwed and fixed into one body by bolts.

[0017] The bottom of the upper column 15 is welded with an upper column flange 3 docked with the sleeve upper flange 4 , and the periphery of the upper column fla...

Embodiment 2

[0021] According to the structure disclosed in Embodiment 1, the chord frame, the upper column 6 and the lower column 8 are pre-processed in the factory. When transported to the construction site in the later stage, only the butt joint assembly operation is required. There is no welding operation requirement on site, and the bolts The layout is also easy to operate manually, which greatly improves the assembly speed and quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com