Asphalt pavement hot in-place recycling anti-rut agent spreader

A technology of anti-rutting agent and asphalt pavement, which is applied in the field of large-scale thermal regeneration construction and maintenance technology equipment of asphalt pavement, which can solve the problems of uniformity, high manual work intensity, cloth that cannot resist rutting agent, and physical injury of construction personnel, etc., to achieve Ensure uniformity and uniformity, improve work efficiency, and spread evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

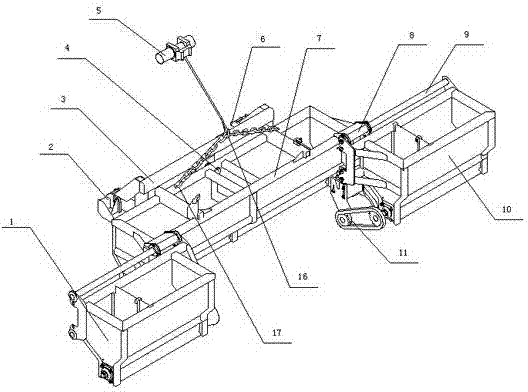

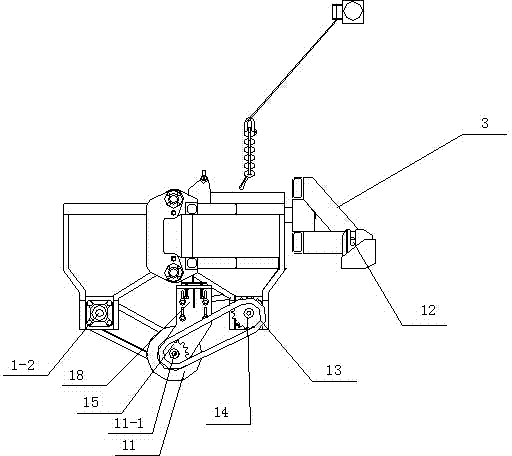

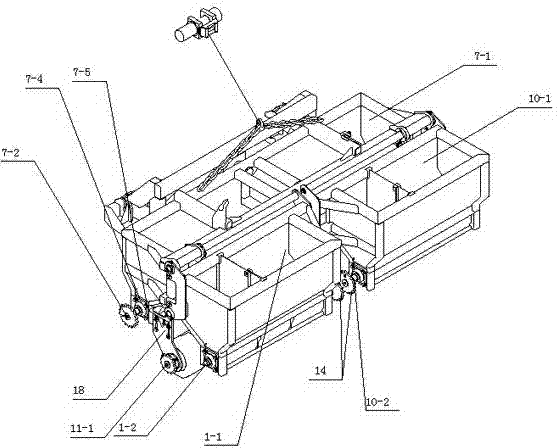

[0018] Hot-in-place regenerative anti-rutting agent spreader for asphalt pavement, including left spreading hopper 1, left fixed seat 2, rotating frame 3, pin shaft 4, winch 5, right fixed seat 6, spreading hopper 7, guide groove 8, guide post 9, Right spreading hopper 10, friction wheel 11, rotating shaft 12, closed chain 13, driven sprocket 14, driving sprocket 15, steel wire rope and steel chain ring 16, friction wheel support 18 etc. The left fixed seat 2 and the right fixed seat 6 are respectively welded into one body with the frame girder on the large-scale thermal regeneration equipment, and the winch 5 is welded to the steel part in the middle of the vehicle frame of the large-scale thermal regeneration equipment through the fixing bracket, and the left fixed seat 2, The right fixed seat 6 and the rotating frame 3 are hinged by the rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com