Separation and purification method of coarse diglycolamine

A technology of diglycolamine and diethylene glycol, which is applied in the field of separation and purification of crude diglycolamine, can solve the problems of poor separation effect and inability to use industrial production, and achieve the effect of simple process, easy operation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

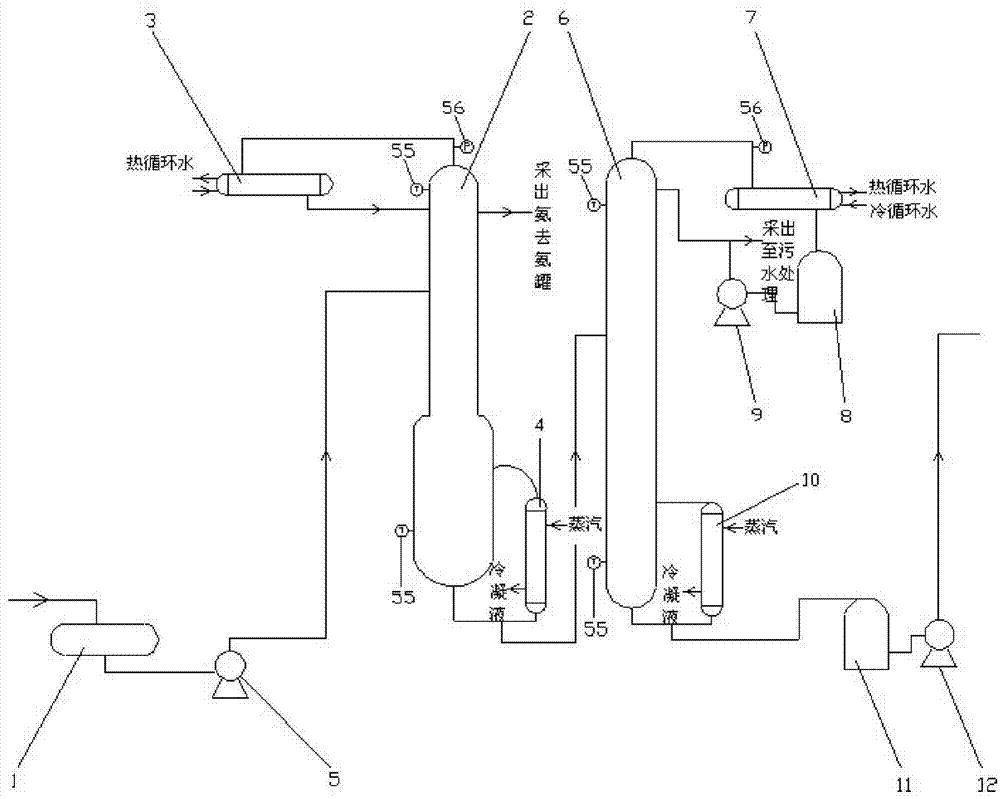

[0028] The present invention will be further described below in conjunction with accompanying drawing.

[0029] As shown in Figure 1, the crude diglycolamine from the crude diglycolamine storage tank 1 is pumped into the deammonization tower 2 through the deammonization tower feed pump 5 to carry out deammoniation, and is deaminated with medium-pressure steam (2.5MPa, 300° C. ) to heat the crude diethylene glycol material in the reboiler 4 of the deamination tower to control the temperature at the top of the tower to be 35-40°C, the temperature at the bottom of the tower to be 170-180°C, and the pressure inside the deamination tower to be 1.1-1.3MPa ( absolute pressure). After the gaseous ammonia coming out from the top of the deamination tower 2 is cooled by the top condenser 3 of the deamination tower to become liquid ammonia, it returns to the deamination tower 2 and is adjusted according to process requirements. A part of the liquid ammonia is refluxed as a reflux liquid, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com