A kind of soybean protein whey wastewater pretreatment method

A whey wastewater and soybean protein technology, applied in the field of soybean protein whey wastewater treatment, can solve the problems of high load of anaerobic and aerobic processes, increased operating costs of enterprises, low COD removal rate, etc. Good dehydration effect, COD and SS reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

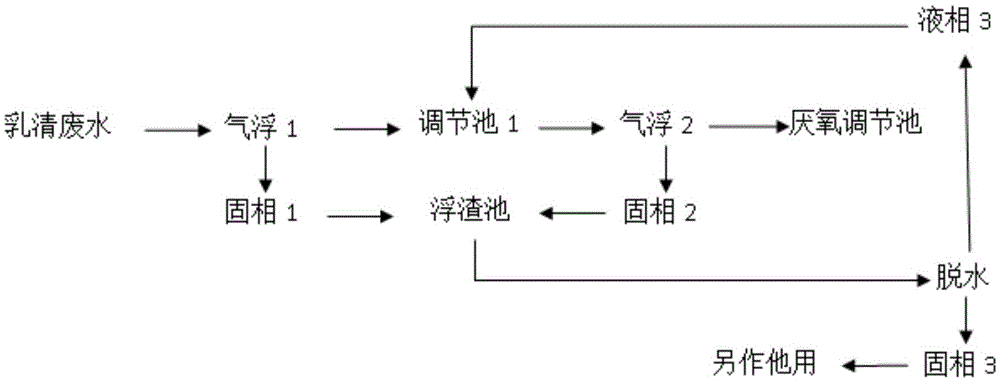

[0025] (1) Air flotation 1: The soybean protein whey wastewater is directly pumped from the production workshop into the sewage treatment workshop, and 1500ppm of polyferric sulfate and 15ppm of anionic amide are added successively, mixed by a mixer and then entered into the air flotation machine 1 for air flotation. The solid phase 1 enters the scum tank, and the liquid phase 1 enters the regulating tank 1;

[0026] (2) Air flotation 2: Add 10.0% calcium hydroxide turbid liquid to the clear liquid in the adjustment tank 1 to adjust the pH to 6.5, then add 1200ppm polyferric sulfate and 12ppm anionic amide successively, mix them with a mixer and enter The air flotation machine 2 performs air flotation, the solid phase 2 enters the scum tank, and the liquid phase 2 enters the anaerobic adjustment tank;

[0027] (3) Dehydration: add 10% calcium hydroxide solution to the solid phase mixture (solid phase 1 + solid phase 2) obtained by air flotation 1 and air flotation 2 to adjust ...

Embodiment 2

[0029] (1) Air flotation 1: soybean protein whey wastewater is directly pumped from the production workshop into the sewage treatment workshop, and 1800ppm of polyferric sulfate and 15ppm anionic amide are added successively, mixed by a mixer and then entered into the air flotation machine 1 for air flotation. Phase 1 enters the scum tank, and liquid phase 1 enters the regulating tank 1;

[0030] (2) Air flotation 2: Add 10.0% calcium hydroxide turbid liquid to the clear liquid in the adjustment tank 1 to adjust the pH to 6.8, then add 1000ppm polyferric sulfate and 10ppm anionic amide successively, mix them with a mixer and enter The air flotation machine 2 performs air flotation, the solid phase 2 enters the scum tank, and the liquid phase 2 enters the anaerobic adjustment tank;

[0031] (3) Dehydration: add 10% calcium hydroxide solution to the solid phase mixture (solid phase 1 + solid phase 2) obtained by air flotation 1 and air flotation 2 to adjust the pH to 11.0, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com