A treatment process for fracturing flowback fluid

A fracturing flowback fluid and treatment process technology, applied in filtration treatment, water/sewage treatment, mining wastewater treatment, etc., can solve the problems of high fracturing construction costs, environmental pollution, waste of resources, etc., to avoid leakage risks, High catalytic activity and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

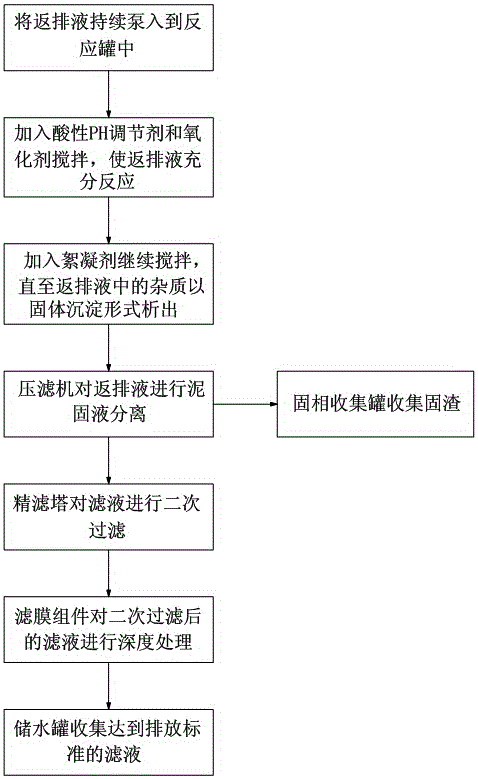

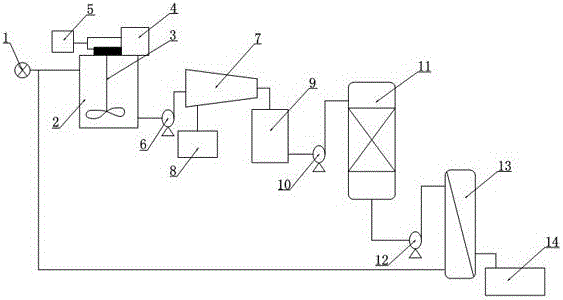

[0036] The invention provides a treatment system for fracturing flowback fluid, such as figure 1 As shown, the treatment system includes a flowback liquid reaction device, a first screw pump 6, a filter press 7, a solid phase collection tank 8, a filtrate fine filtration device, a third screw pump 12, a filter membrane assembly 13 and a water storage tank 14 . The flowback liquid reaction device is used to separate out the impurities in the flowback liquid in the form of solid precipitation, which includes a submersible sewage pump 1, a reaction tank 2 connected to the submersible sewage pump 1, and a A mixer 3 , a dosing tank 4 connected to the reaction tank 2 , and a control cabinet 5 respectively connected to the agitator 3 and the dosing tank 4 ; the reaction tank 2 is connected to a first screw pump 6 .

[0037] The filter press 7 is used to separate the solid-liquid from the flowback liquid after the solid impurities have been precipitated. As a preference, in this embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com