Individual bush separation mechanism of automatic identifying bush loader

An automatic identification and separation mechanism technology, applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of solder melting splash, scrap amount, precision bushing without gaps, etc., to achieve high identification efficiency, The effect of fast feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0009] see figure 1 and figure 2 , the embodiment of the present invention includes:

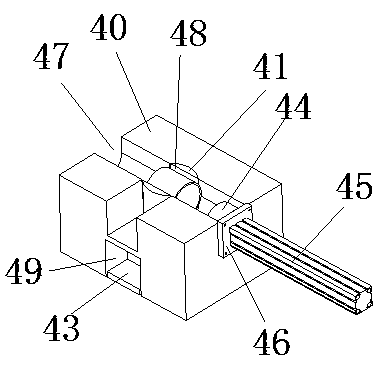

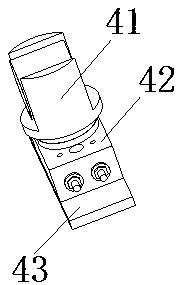

[0010] A bushing unit separation mechanism for a bushing automatic recognition feeder, the bushing unit separation mechanism for a bushing automatic recognition feeder includes a separation body seat 40, a separation rotary mold 41, a turntable cylinder 42, and a turntable cylinder pad Plate 43, pusher die 44, pusher cylinder 45 and pusher cylinder flange 46, the circular hole in the middle of the separation body seat 40 is provided with a rotatable separation rotary die 41, the groove 48 of the separation rotary die 41 and the separation The "T" groove 47 of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com